Spinal Biomechanics

maintenance of stability and performance of kinematic tasks renders the

human body one of the most complex machines known. Within its

structure, the multijoint nature of the human spine possesses its own

unique set of biomechanical challenges. A thorough understanding of the

physical forces that govern the static and the dynamic properties of

this anatomic structure is crucial. In this chapter, a basic and

elemental definition of mechanical concepts and terms is presented as

an initial step to understanding spinal biomechanics.

load has evolved from being an aspect of pure materials science to its

own specific discipline of biophysics called rheology. Commonly used “engineering terms,” such as elasticity, plasticity, viscosity, and strength,

although usually used to describe the properties of pure plastics or

metals, can be applied to the characteristics of the materials that

compose the human spine. These properties determine the relationships

between the individual components of the spine, including ligament,

bone, and disc. These terms can be used to describe and forecast the

interaction of implanted devices within the spine. Combined with

information concerning the biologic processes and the details of tissue

physiology, an understanding of the influence of the local mechanical

environment on fusion healing, disc degeneration, and scoliosis

progression can be achieved.

structure. Similar to a skyscraper, the behavior of the construction as

a whole is determined by the interaction of its individual parts and

materials. Steel, glass, and concrete each have their own mechanical

properties (e.g., elasticity, plasticity, ductility). When used in

combination, however, the properties of the new construction are

determined by the relative interplay between the different materials.

The spinal column is a composite structure of bone, ligament, and

intervertebral disc. Although the material properties of these

individual tissues can be defined easily, prediction of the interaction

between the tissues is much more complex and has been the focus of

countless biomechanical investigations.

through surgical intervention. The orthopaedic spine surgeon is obliged

to possess an understanding of basic biomechanics.

-

Force

-

Stress

-

Strain

is defined as the force required to accelerate a 1-kg mass at 1 meter

per second squared. Mathematically, this is written 1 N = 1 kg × 1 m/s2.

or pascals (Pa). Because of the great magnitudes, the typical unit

expressed for most materials concerning the spine is the megapascal

(MPa), which is equivalent to 106 Pa.

of a material under a particular force (or load). It is the ratio of

the new length over the original length and is expressed as ε = (Lfinal – Linitial) / Linitial = ΔL/Linitial. Because the denominator and the numerator have units of length, strain is a dimensionless parameter and has no units.

-

Elasticity

-

Plasticity

-

Viscoelasticity

are independent of geometry and are independent of each other; they include elasticity, plasticity, and viscoelasticity.

is by examining a spring. When a spring (or other elastic material,

such as bone, which has some springlike properties) is loaded, a

specific amount of deformation is achieved. The deformation is

proportional to the load applied. When the load is removed, the spring

returns to the original geometry. This ideally elastic spring is said

to recover fully from deformation. Up to a specific load, any elastic

material would deform under an applied force (F) and return to its

original geometry on removal of that force. For an elastic material,

the plot of applied forces and resulting deformation would be linear.

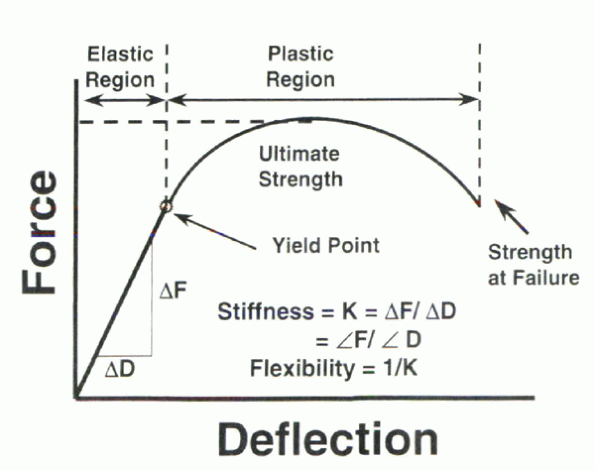

The value of the slope within this linear region defines the stiffness

of the elastic material. The stiffness is designated by K and by

definition possesses units of force/deformation (N/m). This quantity

often is expressed in units of N/mm to express the quantity more easily

because biologic samples such as bone typically do not deform to any

great extent (Fig. 31-1).

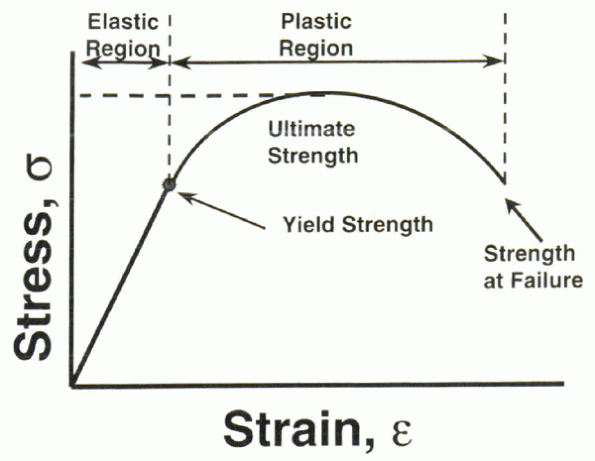

results in a permanent change in the geometry of the specimen on

removal of the deforming force. Plastic deformation is, by definition,

permanent deformation without return to original dimensions. The

plastic region of a material still may possess a linear region;

however, it “recoils” to a point beyond the elastic region. The plastic

region may be long, as the case is for steel or titanium, or it may be

short, as is the case for brittle materials, such as ceramic. The yield point represents the transition from the elastic to the plastic regions (Fig. 31-2). This is the “point of no return” for the material. Any additional deformation beyond the yield point is permanent.

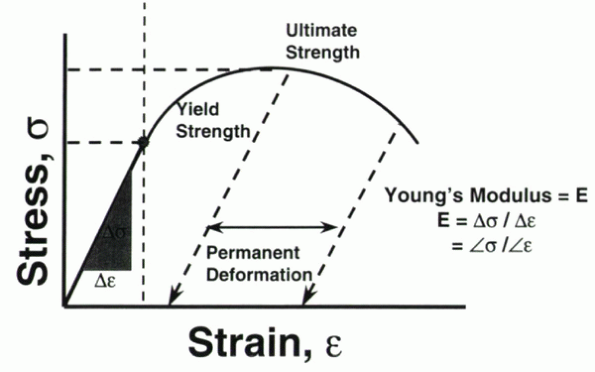

stress versus strain (or the load versus deformation) curve of a

material. In the elastic region of the curve, removal of the applied

load results in nonpermanent change in the geometric dimensions of the

material. When the identical process is repeated in the plastic portion

of the curve, however, a permanent change in deformation results. If a

line is drawn from the point of load release, parallel to the slope of

the elastic curve, it intersects the x-axis of strain (or deformation).

This value is the permanent deformation for the applied load (Fig. 31-3).

|

|

Figure 31-1

Characteristics of the load versus deformation curve under static loading conditions. (The terms “deflection” and “deformation” may be used interchangeably.) |

|

|

Figure 31-2 Stress versus strain curve illustrating the elastic and plastic regions of a material under static loading conditions.

|

Although the manifestation of this characteristic may be dramatic, as

in soft tissues (e.g., muscle, tendons, and ligaments), viscoelasticity

in harder materials (e.g., bone and cartilage) is more subtle.

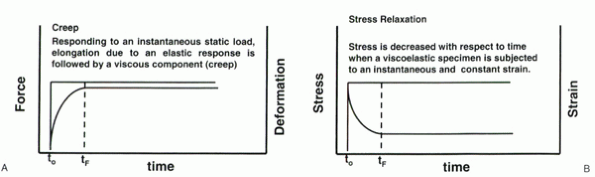

viscosity. Shear and flow are resisted by viscosity. Viscosity is time

dependent in nature (Fig. 31-4). In the case of

an instantaneous load application, a viscoelastic material displays an

initial exponential rise in deformation until a steady state of

deformation is obtained. This equilibrium is achieved when the internal

viscous and material forces are sufficient to resist the collapse of

the applied load. The viscous component of the force resistance is

termed creep and is common to all

viscoelastic materials. The comparable effect is observed when

instantaneous deformation is applied and maintained. In this case, the

viscoelastic properties balance and minimize the internal forces. The

initial stresses decay exponentially to an equilibrium level on

application of an instantaneous and constant strain. This phenomenon is

termed stress relaxation and, similar to

creep, is common to all viscoelastic materials. The resulting

deformation displayed by the material is related to the force magnitude

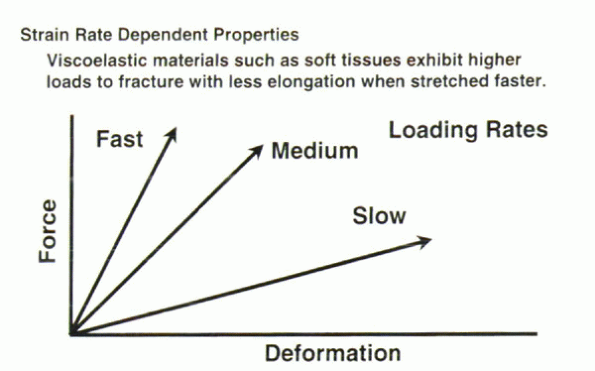

and the rate of force application (Fig. 31-5).

The deformation rate of a viscoelastic material is directly

proportional to the force magnitude applied. In contrast to

nonviscoelastic materials, no elastic return to the original geometry

results when the applied load is removed.

|

|

Figure 31-3

Characteristics of the stress versus strain curve under static loading conditions. Note the similarities to the load versus deformation curve in Figure 31-1. Permanent deformation results at load levels beyond the yield point. |

-

Strength

-

Ductility

-

Fatigue

material properties would be useful. The substance of which an object

is composed determines material properties, such as elasticity and

plasticity. These properties are independent of the geometry. The

structural properties of an object are determined by its shape or

geometry. The steel used to create a piece of sheet metal has the same

material properties as the steel used to create an I-beam. The I-beam,

for its intended use to span long segments and act as a weight-bearing

structure, is much stronger, however. Strength (and ductility and

fatigability) is determined partially by the material in addition to

the geometry or dimensions into which it is formed. A biologic

structure, such as bone, also has material and structural properties.

Bone has a specific elastic modulus, stiffness, and other material

properties. The geometry that the bone assumes, such as a hollow tube

(long bone), influences the strength of the bone. A purely structural

property is bending or torsional resistance. It is determined only by

the geometry of an object.

|

|

Figure 31-4 (A) Visual representation of creep resulting from an instantaneous application of a constant load. (B)

Visual representation of stress relaxation resulting from an instantaneous application of a constant strain. The stress values follow an exponential decrease until equilibrium is achieved. |

at which a material would fail. It is related to the magnitude of force

(or stress) required to cause a structural (rather than material)

failure in the material. Strength is the force beyond which

“catastrophic failure” occurs. It is beyond the yield point of the

material. The ultimate tensile strength describes the maximal tensile force or stress that a structure can sustain before catastrophic failure.

ductile, strong, and lightweight. These characteristics are not

interdependent and are defined uniquely by the characteristics of the

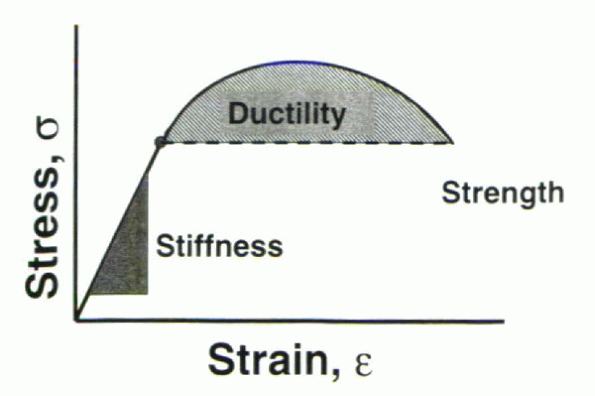

material. In the load-deflection (or stress-strain) curve, the

stiffness (or modulus in the stress-strain curve) is defined as the

slope of the linear region in the elastic portion of the curve (Fig. 31-6).

It is common practice to perform a linear regression of the load (or

stress) versus deformation (or strain) to compute the stiffness (or

modulus). It also is important to examine the regression coefficient, r2. This value ideally would be equal to unity (or 1) if the result were a perfectly straight line.

number of data points taken during the test. Too few data points decrease the r2

value despite a linear trend. This is an important point to note,

especially in the case of biologic tissues, in which viscoelasticity

and loading rate can influence dramatically the profile of the

load-deformation (or stress-strain) curve. In such cases, too few data

points may lead erroneously to a seemingly linear curve and inaccurate

computation of stiffness or the elastic modulus.

|

|

Figure 31-5 In viscoelastic materials, the maximal force achieved and the material stiffness are affected by the rate of applied loading.

|

represents the amount of plastic deformation obtained before failure

(i.e., the total deformation between the yield point and the failure point of the material or implant). Consideration of this property is vital in the design of spinal implants. If a device yields but possesses sufficient ductility such that it does not fail

under continued loading (and if this amount of deformation does not

cause pain clinically), the likelihood of clinical implant failure is

low. In contradistinction, if the implant possesses minimal ductility

and it mechanically yields under physiologic loads, failure is likely.

implant design. In the case of operative scoliosis correction, rods

should be stiff to maintain curve correction and to provide sufficient

spinal stability. The rods also must be strong so as to prevent failure

of the implant or construct under cyclic physiologic (fatigue) loading.

Finally, the rods must be ductile so that the surgeon can contour the

rods to the desired shape to achieve curve correction. If the rod was

not ductile, bending it would lead to potential breaking points that

eventually would lead to implant failure.

|

|

Figure 31-6

Ideal implants display a sufficiently high stiffness property in addition to a large region of ductility to prevent catastrophic failure. |

|

|

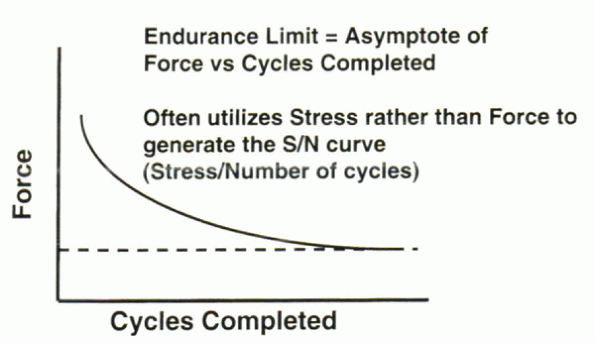

Figure 31-7 Typical load versus cycles to failure curve. At some applied load no failure will occur, regardless of the number of cycles.

|

The number of cycles to failure for a given material may be different

in different loading directions. Bone is strongest under compressive

loads, but it is weakest, and usually fails, under torsion or bending

loads.

This is the load magnitude below which failure would not occur

regardless of the number of cycles applied to the material. This

property is crucial when considering the design and selection of

material for an implant. The endurance limit of the final design should

be well above the anticipated maximal physiologic loads.

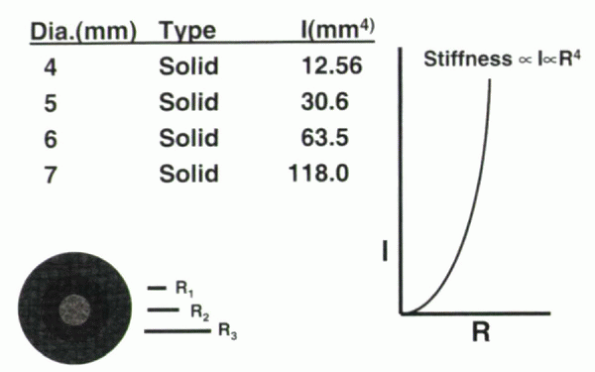

related to the cross-sectional area of a structure and is a fundamental

geometric property of the structure. The moment of inertia describes

the spatial distribution of material within a structure with respect to

a particular axis of rotation or bending. The equation is expressed as

I = Σ miri2—the sum of each elemental mass (mi) that is located at a distance (ri)

from the neutral or selected axis. For most geometric structures, with

a central axis of symmetry, such as a round rod or rectangular plate,

moments of inertia can be calculated using simple equations.

only and is not related to the material used. One of the most useful

applications of this property is calculation of resistance to bending

for various structures. A large increase in the bending resistance of a

rod can be achieved by small increases in the rod’s diameter (Fig. 31-8).

For cylindrical objects with a neutral axis through their center, the

moment of inertia is proportional to the fourth power of the rod radius

(r). The equation defining this relationship is:

the moment of inertia for a 7-mm rod is 10 times that of a 4-mm rod.

|

|

Figure 31-8

The moment of inertia for a cylindrical rod is proportional to the fourth power of the radius. Small increases in radii can manifest large increases in the moment of inertia and the resulting stiffness of the rod and construct. |

to the height cubed. To a lesser degree, increases in the height of the

object (or thickness) result in exponential increases in the bending

resistance. Using an equation, this can be expressed as:

inertia creates a stiffer rod. The overall effects of spinal implants

must be considered in concert with the mechanical properties of the

spinal column itself, however. Although the spine is a composite

structure by itself, it becomes more so with the introduction of

instrumentation. Using the example of the rod, the resulting stiffness

is a combination of spinal column stiffness and the rod. This stiffness

is highly influenced by the location of the implant within the spine

and the dimensions and materials properties.

definition unknown. Although various underlying genetic, neurologic,

muscular, and skeletal mechanisms have been suggested, none seem to be

solely responsible for development of this disorder. More recently, a

biomechanical explanation of the initiation of scoliosis has been

suggested. This explanation is grounded in considering the spine as a

buckling column.

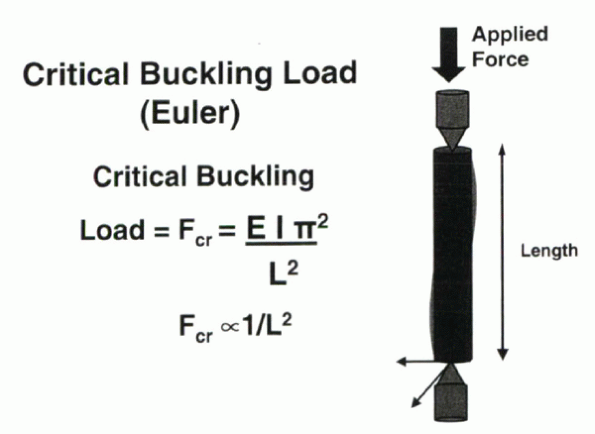

thin (compared with the dimensions of the entire body) column. Under

compressive loading, such a structure would fail primarily through

“buckling.” Euler computed that the critical buckling load is defined

by:

It is the load at which buckling is initiated, and it is inversely

proportional to column length. It follows that the longer the column,

the less force required to achieve buckling.

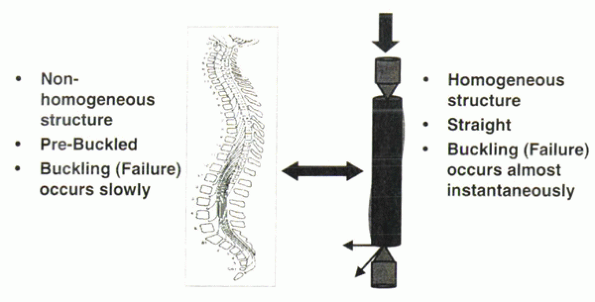

of homogeneous material. The human spinal column is not such a

structure. It is composed of discs and bone among a complex of muscles

and ligaments. The natural curvature of the spine (cervical lordosis,

thoracic kyphosis, and lumbar lordosis) resides in an already buckled,

or “prebuckled,” condition. Although Euler considered buckling to be

catastrophic for a structure, this is not the case for the human spinal

column.

occurs over time. It does not lead to catastrophic failure immediately.

Scoliotic buckling results in disharmony of the normal spinal

curvature, producing abnormal coronal buckling. The critical buckling

force to produce a scoliotic curve may be used to predict what loads

(from the head, trunk, and extremities) might lead to a progressive

scoliotic curve (Fig. 31-10). The critique of

such theoretical calculations is that they do not take into account the

osteologic and ligamentous responses to these forces, which would be

crucial in the growing adolescent spine.

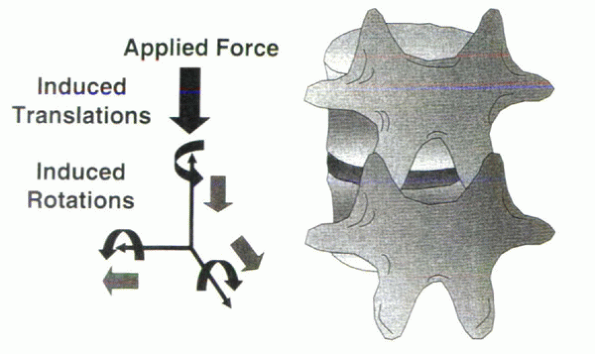

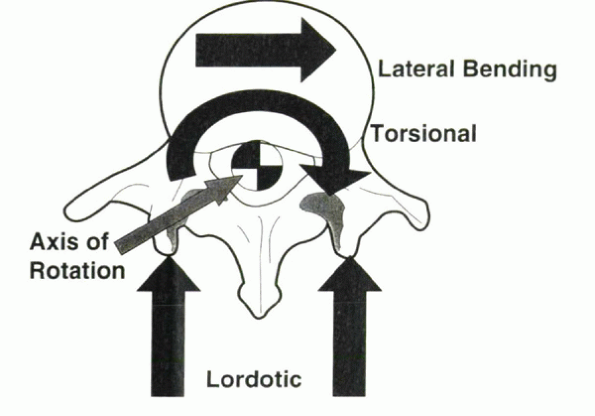

When the lumbar spine undergoes rotation, lateral bending also occurs.

This relationship is commutative, in that lateral bending of the spine

induces rotation. In reverse, derotation of the spine should correct

coronal deformity. This correction is maximized by resection of other

structures, such as the costovertebral joints in

the

thoracic spine that propagate rotation. The resultant coupled motion

decreases the scoliotic curvature. Conversely, the rotation of the

spine leads to rib cage deformity.

|

|

Figure 31-9

Euler’s formula for the force transmitted through a long cylindrical column supported and loaded by a single point. The critical buckling load for a column is inversely proportional to the square of the column length. |

|

|

Figure 31-10 The human spine is a prebuckled nonhomogeneous structure in which pathologic buckling occurs gradually.

|

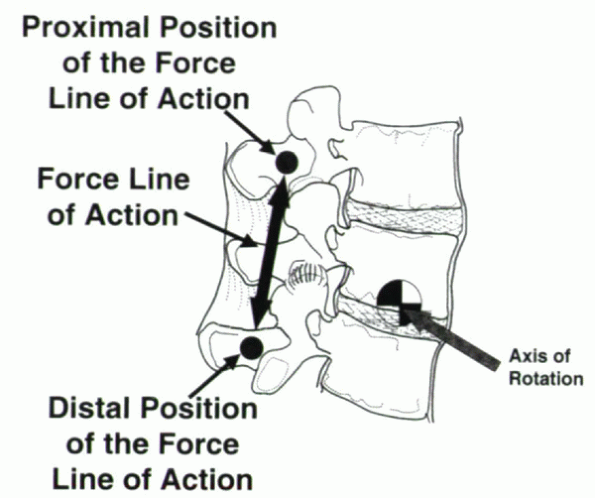

about which all other parts rotate. In the spine, the axis is not

located at a single point, but because of the intricacy of the

three-joint structure, it moves within a complex pattern (or

collection) of points. To preserve the relative position of the neural

elements, the axis of rotation in the transverse plane is located

within the spinal canal (Fig. 31-12). Although

considerable work has been done in attempting to locate the locus of

the axis of rotation during flexion/extension and lateral bending, the

definitive answer remains elusive because in vitro investigation can

only simulate in vivo motion, with one vertebra moving in relation to

an adjacent fixed vertebra. Physiologically, both vertebrae are moving

relative to a global reference frame and relative to each other (Fig. 31-13).

The local reference frame is in motion. With that said, it generally is

believed that the sagittal axis of rotation is located within the

center of the intervertebral disc (Fig. 31-14).

|

|

Figure 31-11 Force direction generated by proper instrumentation and implantation can be used to control spinal deformity in various planes.

|

|

|

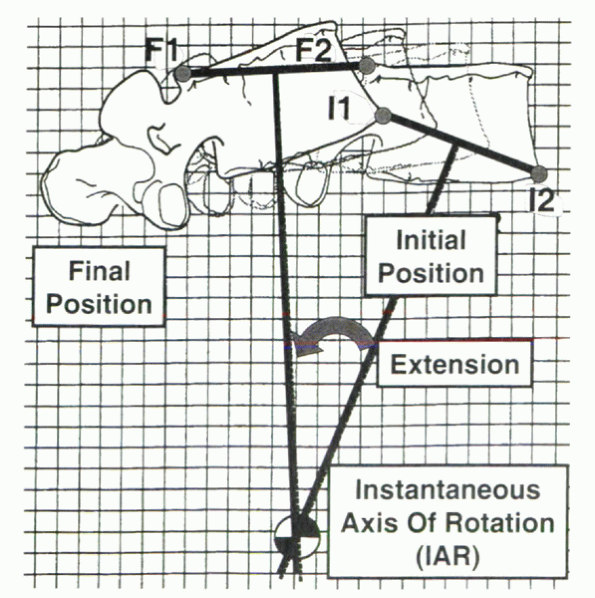

Figure 31-12 Instantaneous axis of rotation during motion of a single vertebral body in relation to a fixed location.

|

|

|

Figure 31-13

The instantaneous axis of rotation (IAR) in vivo is influenced by the relationship of one vertebra with another and the orientation of both vertebrae in relation to a global reference frame. |

|

|

Figure 31-14 During flexion/extension movements, the estimated axis of rotation is located within the center of the intervertebral disc.

|

generation of geometrically scalable anatomic models complete with soft

tissues. Although this undertaking may yield new insight, the focus

should remain on the influence of physiologic loading. From a practical

perspective, such complex loading conditions would be enormously

difficult to simulate in an in vitro setting. Even if computationally

possible, experimental verification would be nearly impossible, with

the task remaining an academic exercise.

L, Lange U, Knop C, et al. Evaluation of the mobility of adjacent

segments after posterior thoracolumbar fixation: a biomechanical study.

Eur Spine J 2001;10:295-300.

PJ Jr, Polly DW Jr, Cunningham BW, Klemme WR. The effects of hook

pattern and kyphotic angulation on mechanical strength and apical rod

strain in a long-segment posterior construct using a synthetic model.

Spine 2001;26:627-635.

PA, Jain GM, Wittenberg RH, Nolte LP. Load-sharing characteristics of

stabilized lumbar spine segments. Spine 2000; 25170-25179.

TR, O’Brien M, Felmly WT, et al. Instantaneous axis of rotation as a

function of the three columns of the spine. Spine 1992;17: S149-S154.