Biomechanics of Fractures and Fracture Fixation

of biomechanics, and demonstrates how these concepts can be used to

understand the basic functions of bone fracture fixation devices and to

avoid clinical problems associated with the mechanics of fracture

fixation. Emphasis has been placed on addressing practical problems.

First, fundamental concepts of mechanics as they apply to the practice

of orthopaedic fracture fixation are explained. This is followed by a

short discussion on the mechanical organization of bone, its ability to

carry load, and the relationship of applied forces and specific

fracture patterns. A discussion of mechanisms of bone and joint injury,

including specific mechanisms observed in car crashes is next

presented. Description of the mechanics of healing bone follows, which

is relevant to understanding the timing of applying progressive load to

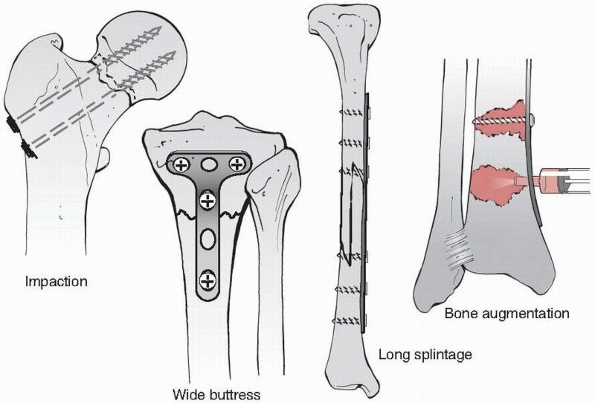

healing fractures in patients. Finally, the performance of various

types of fixation systems is discussed, with emphasis on fixation of

difficult fractures, such as the femoral neck and the tibial plateau,

and those involving osteoporotic bone. The focus of the discussion is

not on comparing the various specific devices available, but rather on

demonstrating the common mechanical principles involved in fracture

fixation so that potential problems common to various devices can be

recognized and avoided.

fixation, the fundamental mechanical question remains: is the fixation

system stiff and strong enough to allow the patient early mobility,

before bony union is complete, without delaying healing, creating bone

deformity, or damaging the implant, and yet flexible enough to allow

transmission of force to the healing fracture to stimulate union? The

issue of which brand of fixation is strongest or stiffest is not

specifically addressed because that is not the standard by which

different devices should be judged. Within a range of fixation

stiffness it has been shown that bone will heal, with the amount of

stabilizing callus compensating for more flexible fixation.

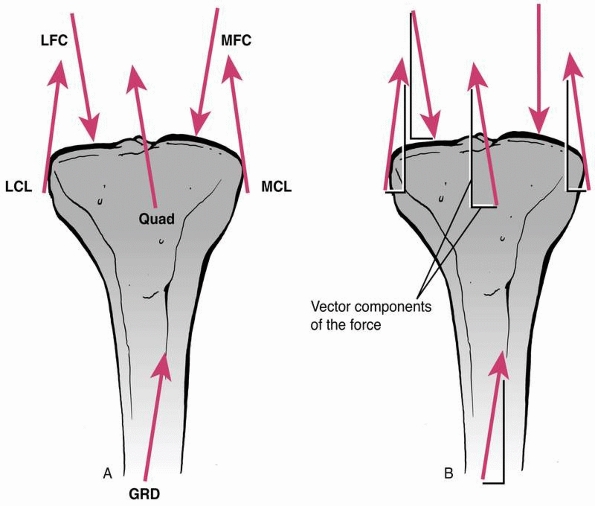

demonstrates, loads in many different directions may act on a fixed

fracture, including body weight, and forces induced by muscle

contraction and ligament tension. A force causes an object to either accelerate or decelerate. It has magnitude (strength) and acts in a specific direction, therefore it is termed a vector.

However complex the system of forces acting on a bone, each force may

be separated into its vector components (which form a 90-degree

triangle with the force). Any of several components, acting in the same

direction, can be summed to yield the net or resultant force.

As a simple example, consider the resultant force acting at the

shoe/floor interface during ambulation. It can be separated into a

vertical force because of

body

weight and a horizontal frictional force that produces the forward

thrust. Similarly, muscle forces can be separated in the same

manner—one force along the axis of the long bone and one perpendicular.

The components of the different forces that act in the same direction

can be added, and the resultant force acting on the bone can then be

found. This concept is important when designing fracture fixation

systems because it allows the designer to size the implants so that

they can withstand the mechanical loads applied without failure.

|

|

FIGURE 1-1

Force vectors acting on a long bone during functional use as a result of muscle, tendon, and external forces. A vector indicates that the force has both magnitude and direction. The complex system of forces can be divided into components acting perpendicular and parallel to the ground, or the axis of the bone, then added to arrive at an overall resultant force. |

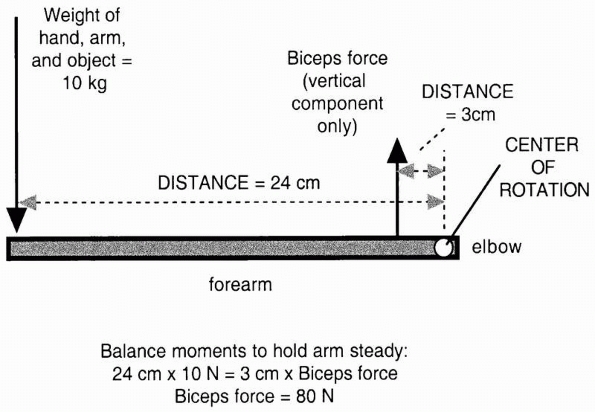

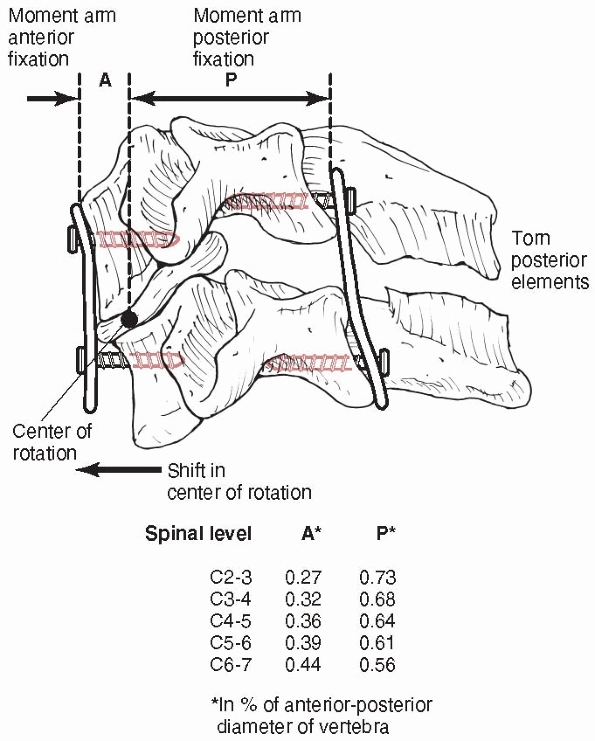

cause it to displace in a linear direction (translation) and those that

cause it to rotate around a joint center. Muscles typically cause a

bone to rotate (e.g., the biceps causes the forearm to rotate, the

anterior tibialis causes the foot to dorsiflex). When a force causes

rotation, it is termed a moment and has a moment arm.

The moment arm is the lever arm against which the force acts to cause

rotation. It is the perpendicular distance of the muscle force from the

center of rotation of the joint. As shown in Figure 1-2,

the moment or rotary force is affected not only by the magnitude of the

force applied, but also by its distance from the center of rotation. In

the example, two moments act on the outstretched arm. The weight

carried in the hand rotates the arm downward, while the balancing

muscle force rotates the arm upward. Equilibrium is reached by

balancing the moments so that the arm does not rotate and the weight

can be carried. Note that to achieve this, the muscle force must be 8

times as large as the weight of the object, arm, and hand because its

moment arm or distance from the center of the joint is only one eighth

as long.

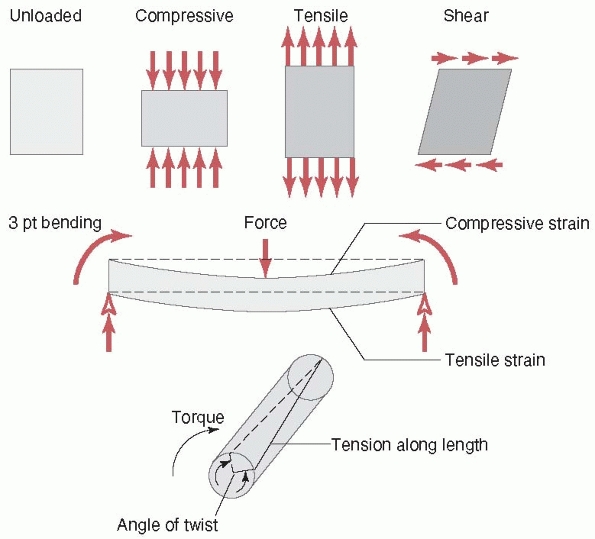

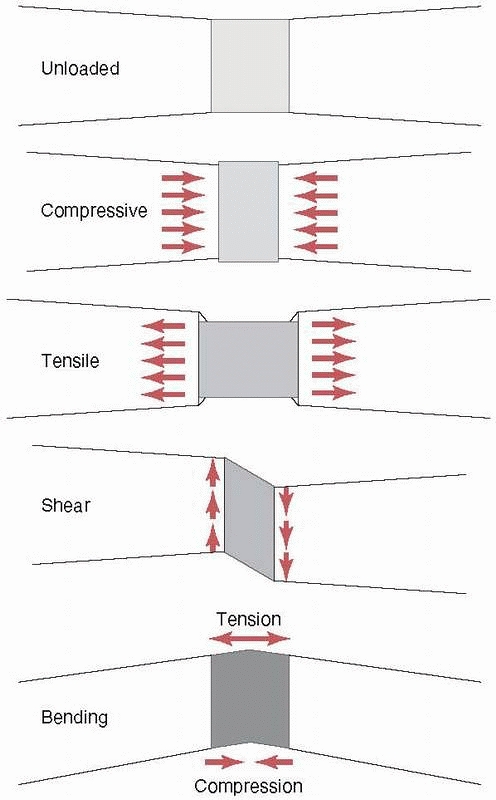

causes it to bow at the center. The forces and moments that act on a

long bone during functional use produce three basic stresses on the

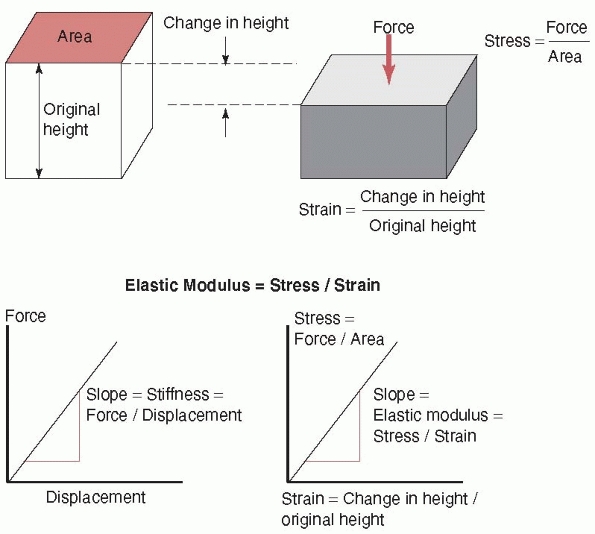

healing fracture region: tension, compression, and shear (as shown previously, all forces can be reduced to their basic components). Stress, as shown in Figure 1-4,

is simply the force divided by the area on an object over which it

acts. This is a convenient way to express how the force affects a

material locally. For example, comparing two bones, one with half the

cross-sectional area of the other, if the smaller bone is subjected to

half the force of the larger bone, the stress experienced by each bone

would be the same. Therefore, a smaller woman with less weight

has

proportionally smaller bones to keep the stresses on the bone tissue

similar to that of a larger and heavier man. The stresses acting on

fracture callus as a result of the different forces are shown (in an

idealized case) in Figure 1-5. Just as stress is normalized force (force per unit area), so can length changes be normalized. Strain

is simply the change in height or length that a bone undergoes during

loading divided by its original height or length, as shown in Figure 1-4.

Under the same force and for bones of similar composition, a bone twice

as long will experience twice the length change. Nevertheless, the

strain will be the same in both cases because the strain (in the longer

bone) will be twice the change in length divided by twice the original

length.

|

|

FIGURE 1-2

In this example the outstretched arm is a lever. The moment or load that rotates the arm downward around the elbow, the center of rotation, is defined as the product of the weight of the object arm and hand X distance from the elbow (for simplicity the center of gravity of the hand, arm, and object are combined). This moment must be counteracted by a moment in the opposite direction, because of the vertical component of the biceps muscle acting through its lever, which is smaller than the lever arm of the weight arm and hand. The biceps force is then calculated from (10 kg × 24 cm)/3 cm = 80 kg. The biceps force is much greater than the weight of the object arm and hand because its lever arm is smaller. |

|

|

FIGURE 1-3 Top:

Basic forces acting on a long bone and the deflection of the bone in response. Compression shortens the length, tension increases the length, and shear deforms the shape of the bone (middle), bending causes the bone to bow, and (bottom) torsion results in twisting about the long axis. |

|

|

FIGURE 1-4

The stress is defined as the force acting on a surface divided by the area over which it acts. Strain is the change in height or length of the object under load divided by its original height or length. Stiffness is defined as the slope of a force versus displacement graph; that is, the change in force divided by the corresponding change in displacement. Elastic modulus is the corresponding slope but of a stress versus strain graph. |

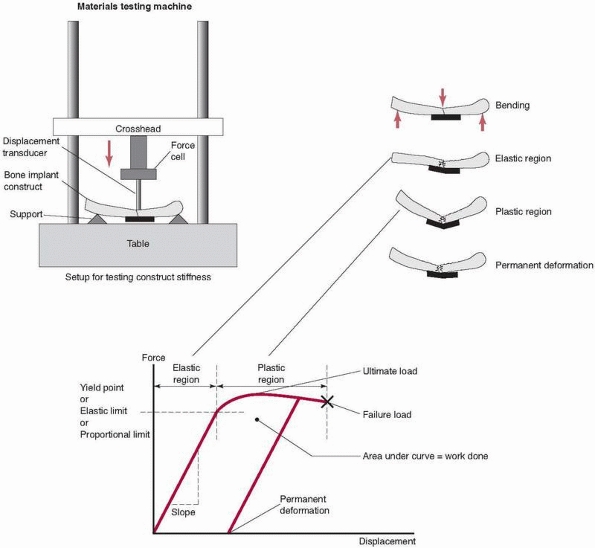

relate to the properties of the substances that make up each component

(bone, stainless steel, titanium). As load is applied to the construct

in a testing machine, the construct deforms. This deformation is termed

elastic because when the load is removed,

the construct will return to its original shape (an important

consideration in preventing malalignment of the bone fracture

components). At some load, however, the construct becomes overloaded,

entering the plastic

range. If the load is released after loading in the plastic range but before failure, some permanent deformation

remains in the construct. Practically, this represents a bent plate,

fixator, or rod and a malaligned fracture. The point at which elastic

behavior changes to plastic is termed the yield point.

The elastic range represents the working range for the fixation

construct. Its two most important properties are its yield point, which

defines its safe maximum functional load, and its stiffness, or the

amount it deforms under load in the elastic range. (A third very

important property, fatigue, will be discussed later.)

|

|

FIGURE 1-5

Resulting stresses acting in fracture callus in a idealized case with each of the basic forces applied (top to bottom): unloaded, compressive stresses along the bone axis and expansive stresses perpendicular to the bone axis as a result of compression, tensile and contraction stresses caused by tension, distortion as a result of shearing; and tension on the convex side, compression on the concave side, and internal shearing caused by bending. |

points and stiffnesses for loads acting in different directions. An

example is a half-pin external fixator construct applied to a tibia,

with the pins oriented anterior-posteriorly. The stiffness is much

greater in anterior-posterior bending than medial-lateral bending for

this construct. Another property to consider is the work done

in deforming a fixation construct. The product of the force applied and

the distance the construct bends is defined as the work done, and is

represented by the area under the forcedisplacement graph of Figure 1-6. Toughness

can be defined as the work done to fracture a construct or material,

including both the elastic and plastic regions of deformation. A

material may be flexible and tough (e.g., rubber, or a child’s bone

that deforms but is difficult to break) or stiff but brittle (e.g.,

glass, elderly bone), if it cannot absorb much deformation without

fracturing.

the material from which the fixation device is made and its shape

(considering an ununited fracture in which the fracture callus

contributes little to structural properties). A construct made of

higher elastic modulus materials will be stiffer (for example,

stainless steel as compared to titanium). The stiffness of a construct

is found by dividing the force applied by the deformation that the

construct exhibited. The elastic (or Young)

modulus is determined by dividing the stress applied by the resulting

strain. Unlike whole constructs, in which case it is difficult to

determine stress (because it is hard to define the area over which the

force is applied and at least two different materials are involved),

uniform blocks of materials can be characterized by their elastic

modulus. The moduli of some common orthopaedic materials are given in Table 1-1.

As shown, the elastic modulus of titanium alloy is about one half that

of stainless steel, so given two plates of the same size and shape, the

titanium plate has about one half the stiffness of the stainless steel

plate. This can be important to consider when using new devices made of

different materials.

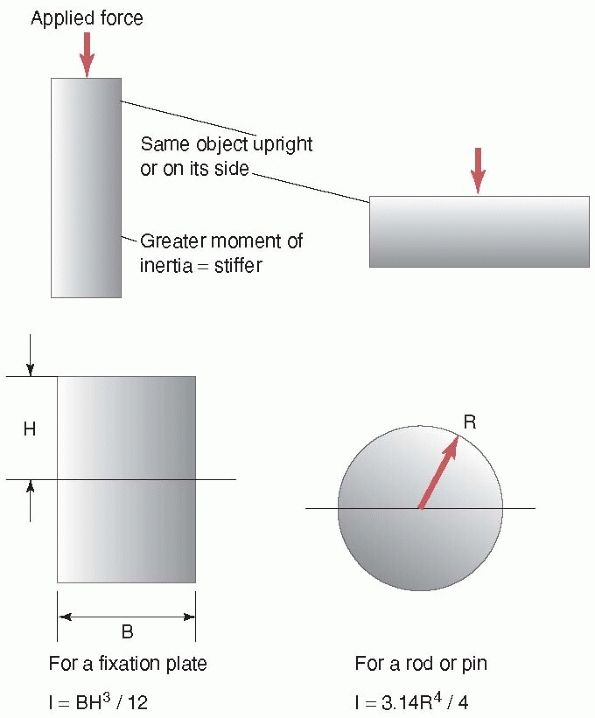

the same wooden 2 × 4 beam that bends easily when load is applied to

its wider surface becomes much stiffer when load is applied to its

narrower surface. This is because, in the latter case, the material of

the 2 × 4 resisting the load is distributed further away from the

center of the beam (note that in this example, the material of the beam

did not change, just its orientation relative to the load applied).

This concept of distribution of material is reflected in the shape

property, moment of inertia. The moment of

inertia provides a measure of how the material is distributed in the

cross section of the object relative to the load applied to it. The

farther away the material is from the center of the beam, the greater

its stiffness. Steel I-beams were developed to take advantage of this

concept; that is, gaining greater stiffness for the same amount of

material. For cylindrical objects like rods, pins, or screws, their

stiffness is related to the 4th power of their diameter. This is why,

as shown in Figure 1-7, for rods made of the

same materials and of similar thickness, a 16-mm diameter

intramedullary rod is 1.7 times as stiff as a 14-mm rod [(16/14)4], and a 7-mm diameter pedicle screw is 1.85 times as stiff as a 6-mm diameter screw.

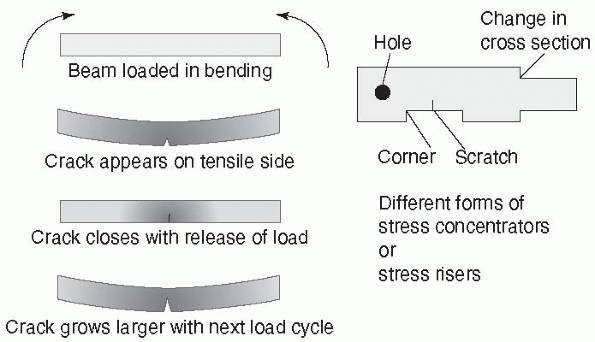

under cyclic loading. Load can be applied that remains below the yield

point of the construct, yet progressively creates a crack that grows

until the local stress in the region of the crack exceeds the yield

point and the construct fails. Some materials have an endurance limit

such that they can support a certain level of load indefinitely without

failure. An important aspect to fatigue performance of a fixation

construct is the effect of a stress concentrator.

In completely uniform materials, the stresses, in tension for example,

will be almost identical throughout the material. Fixation devices have

holes, screw threads, and other features in which shape changes occur.

A very radical change in shape (as shown in Figure 1-8,

the sharp corner between threads of different diameter in a fixation

screw) causes a stress concentrator at the corner. This explains why

the

base of a screw thread, the place at which it meets the shaft of the

screw, has rounded corners. The stresses on a fracture construct are

increased when applied in heavier patients, with poor bone-to-bone

contact across the fracture site, delayed union, early weight bearing

before the fracture has united, and when smaller low-profile fixation

devices are used. For these circumstances, consider the use of larger

implants, taking care not to create stress concentrators by scuffing or

scratching the implant, and delay weight bearing until some fracture

consolidation is apparent. These steps can increase the amount of load

cycles that the implant can bear without fatigue failure.

|

|

FIGURE 1-6 Top left:

A fixation construct (bone-fixation-bone) set up in a mechanical testing machine. In this example a long bone is fixed with a plate and subjected to bending. Top right: The construct during loading in the elastic region, plastic region, and with permanent deformation. Bottom: The resulting measurements from the testing machine, which measures force applied and displacement at the point of the applied load. The graph demonstrates the elastic region, in which the construct acts like a spring, returning to its original shape after the load is released; the plastic region, in which the plate may have permanently bent; and the failure load, in which the fixation fails. |

can occur. Stress corrosion combines the effects of the local growth of

the crack resulting from cyclic loading with galvanic corrosion. A galvanic cell

describes a local environment in which electrons flow from the more

negative to the more positive material when immersed in a liquid

conductor (saline in this case) (Fig. 1-9).

Material is actually removed from the more negative electrode, such as

the surface of the plate during galvanic corrosion. In a fixed

fracture, the dissimilar materials are the surface of the plate (for

example, stainless steel), which

creates

an oxide surface coating, and the same material within the just opening

crack, which has not yet developed the oxide film. The conductive fluid

is the blood and saline found in the surrounding tissues. Galvanic

corrosion can accelerate the failure of an implant, even when the

implant is loaded well below its yield point, by increasing the rate at

which the crack grows, because along with yielding at the site of the

crack, material at the crack is being removed by the corrosion process.

Another mechanism of corrosion, termed fretting,

results when the surfaces of two implants rub together, such as the

head of a screw against the surface of the plate through which it

passes. Crevice corrosion, which is not

common in modern orthopaedic materials, results from small galvanic

cells formed by impurities in the surface of the implant, causing

crevices as the material corrodes.23

|

TABLE 1-1 Basic Engineering Properties of Common Biologic and Implant Materials

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

FIGURE 1-7 Concept of moment of inertia or the effect of the geometry of an object on its stiffness. Top:

Looking at the edge of a wood 2 × 4 (used in home building); left, the 2 × 4 with the load applied on the narrower side is stiffer than the same 2 × 4 with the load applied on its wider side. The area of the 2 × 4 is farther away from the central axis when the load is applied on the narrower side. Bottom: The moment of inertia is a term used to describe how the material is distributed within an object. Left, for a plate, looking at its edge, the moment of inertia and the stiffness increase directly with the width of the plate and the cube of its height. For a tube, such as an intramedullary rod, the moment of inertia increases with the 4th power of its diameter. Therefore a 16-mm diameter IM rod is 1.7 times as stiff as a 14-mm rod, and 2.3 times as stiff as a 13-mm rod, if all the rods have the same thickness and are made of the same material. |

|

|

FIGURE 1-8 A stress concentrator is a region of an object in which stresses are higher than in the surrounding material. Left:

Taking the example of a fracture plate subjected to bending, the bottom surface elongates under load. In the region of highest tensile forces, a scratch starts to grow into a crack that closes when the load is released, then reopens slightly larger with the next load cycle, eventually growing to a point at which the plate fails. Crack growth is accentuated by stress corrosion, poor bone-to-bone contact at the fracture, and by loads applied by heavier patients. Right: Stress concentrators (sometimes referred to as stress risers) occur around holes, sharp corners, from scratches, and at corners from changes in cross section. |

|

|

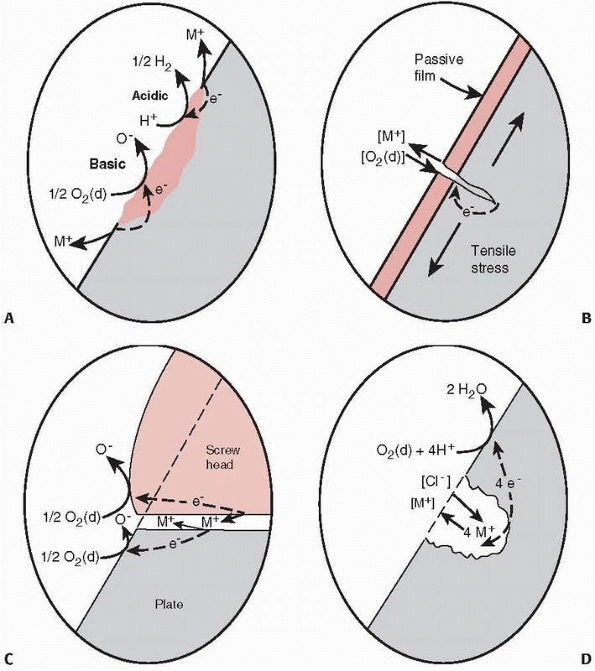

FIGURE 1-9 A.

Illustration of crevice corrosion, with a local galvanic cell caused by an impurity in the surface of a plate and ions, M+, being released, resulting in loss of material and formation of a crevice. B. Stress corrosion occurs by a local galvanic cell setup between the material at the tip of the crack, which just opened and has not oxidized, and the remaining oxidized surface of the plate. The released ions enhance crack growth occurring from loading. C. Fretting corrosion caused by the loss of the oxide layer on the surface of a plate caused by rubbing of the base of the screw against the plate. D. Galvanic corrosion around a scratch or pit in the plate.23 |

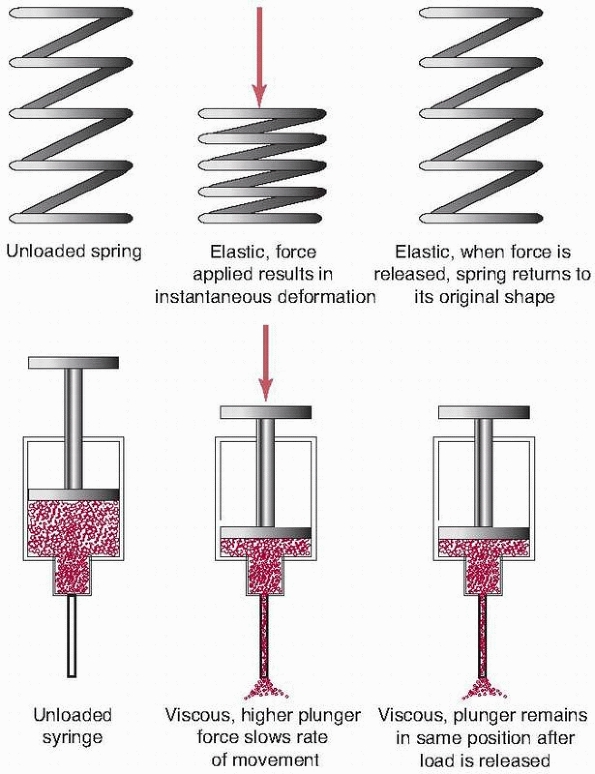

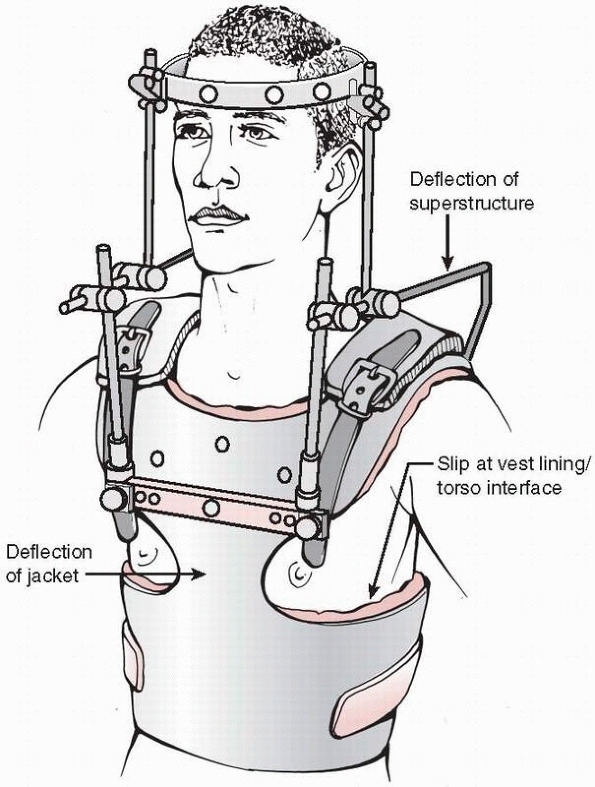

Biologic materials do not act as pure springs when load is applied to

them. (A spring deforms under load, then returns to its original shape

when the load is released.) For example, if a load is applied to a

tendon, and the load is maintained for a period of time, the tissue

will continue to deform or creep. This is

the basic principle behind stretching exercises. Under a constant load,

a metal fixation plate will deform and remain at that deformation until

the load is removed (elastic behavior). In contrast the tendon both

deforms elastically and creeps, exhibiting both viscous and elastic

behavior. This property has important implications for certain types of

fixation, especially those that rely on loading of

soft tissues, such as in certain types of spinal fixation (to be discussed later).

In simple terms, stretching a soft tissue can be thought of as

stretching two components, an elastic one and a viscous one, which make

up that tissue. For example, consider a spring connected in series to

the handle of a syringe (Fig. 1-10). When a

compressive force is applied, the spring instantly compresses,

representing the elastic response of the tissue. The syringe plunger

starts to displace and continues as it pushes fluid through the

orifice. If the force is held constant, the plunger will continue to

move, representing the viscous creep of the tissue. If the compressive

force is applied slowly, the syringe handle offers little resistance.

As the rate of force application increases, the resistance of the

syringe to motion increases. This represents the increase in stiffness

of the tissue at higher loading rates. That is, the stiffness of the

tissue depends upon the rate at which the load is applied.

to failure of ligament and bone. At low loading rates, ligament is

weaker than bone and the ligament fails generally in midsubstance. At

higher loading rates, the ligament becomes stiffer, and failure may

occur by avulsion of the bony attachment of the ligament. Stress relaxation

occurs if the applied force, instead of increasing, is held constant.

As the fluid flows out of the syringe, without further movement of the

plunger, the internal force decreases. These three properties—creep,

stress relaxation, and load rate dependence—make up the basic tissue

viscoelastic properties. It should be appreciated that the model used

in this discussion is a simple linear series model, for explanation

purposes only. Nevertheless, more complex models using combinations of

these basic components have successfully described the observed

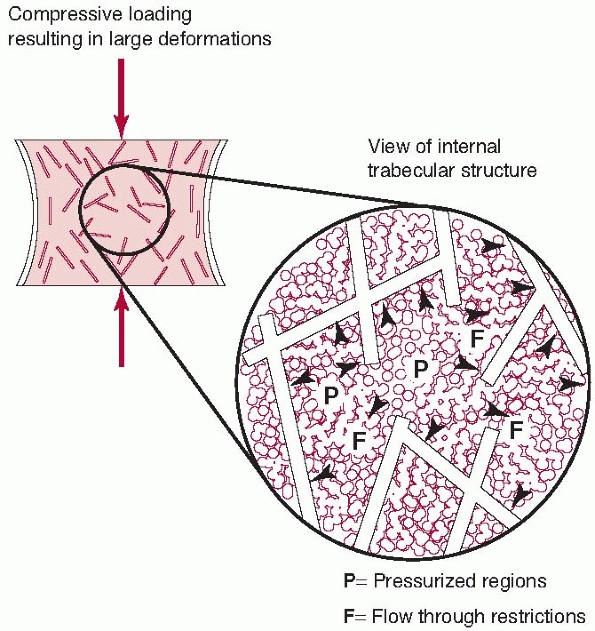

properties of tissues. Another example of tissue viscoelasticity,

besides tendon and other soft tissues, is found in trabecular bone (for

example, spinal vertebrae). In this case, the trabecular structure acts

as the spring component, while forcing the interstitial fluid through

the porous matrix as the trabeculae deform represents the viscous

component. Under higher loading rates, there is resistance to flow,

increasing the internal pressure and therefore the stiffness of the

structure. These effects have been observed at high loading rates, such

as during fracture (Fig. 1-11).32

|

|

FIGURE 1-10

Viscoelastic response in a biological tissue can be explained by considering and combining the properties of two devices, a simple spring and a fluid-filled syringe. The elastic or spring component instantly compresses when a load is applied to it. When the load is released, the spring returns to its original shape. When a load is applied to the viscous component, represented by the syringe, fluid is forced out the needle. If the load is released, the plunger does not return, but remains in its final position, representing the creep property of the tissue. Further, if the force is applied to the plunger more rapidly, there is greater resistance to motion, explaining the increased stiffness of tissue to increased rates of loading. Combinations of these simple components can be used to describe the mechanical properties of biologic tissues. |

forces, but these forces can be resolved into basic components that

create tension, compression, shearing, twisting, and bending. These

forces cause internal, compressive, tensile, and shear stresses in the

tissue. The stiffness of a fixation construct used to stabilize a

fracture describes how much it deforms under a given load acting in a

specific direction. Stiffness may vary with direction and is highly

dependent on the shape of the fixation construct. The effect of shape

is described by the moment of inertia. In combination with the moment

of inertia, the elastic modulus of the material describes how stiff the

fixation will be under load, and its ability to withstand the forces

of, for example the patient’s weight during ambulation. Failure of

fixation can come not only from loading above its yield point but also

as a result of repetitive stress. Repetitive loading can cause growth

of a crack at a stress concentrator, and can be significantly

accentuated by corrosion when the implant is immersed in bodily fluids.

Biologic tissues behave viscoelastically; that is, they creep under

constant load, stress relax when the elongation is fixed, and increase

in stiffness as the rate of load application increases.

In this chapter, these mechanical properties are described in basic units of measurements, defined in Table 1-2.

|

|

FIGURE 1-11 Trabecular bone possesses some features of the spring and syringe viscoelastic model described in Figure 1-10,

although it should be appreciated that this is an idealized model. The trabecular structure acts as the spring element. At higher loading rates, the interstitutial fluid resists flowing through the trabecular spaces, causing increased internal pressure and greater bone stiffness. This anatomical feature allows vertebrae and the metaphyseal ends of long bones to resist dynamic loads caused by rapidly applied forces.32 |

|

|

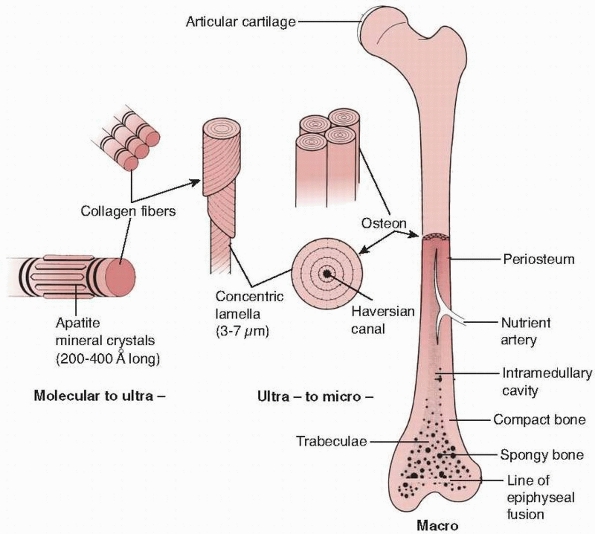

FIGURE 1-12

The hierarchical structure of bone is demonstrated. At the lowest level of organization, the ratio of mineral crystals to collagen fibrils determines elastic modulus of the combined material, as shown in Figure 1-13. At the next level, the fiber orientation is important in determining the difference in strength of bone in different directions. At the final level, the lamella of bone fibers form haversian systems that, particularly in cortical bone, are oriented in the direction of the major loads the bone must support. |

|

TABLE 1-2 Definitions of the Units Used to Describe the Basic Properties of Fracture Constructs

|

|||||

|---|---|---|---|---|---|

|

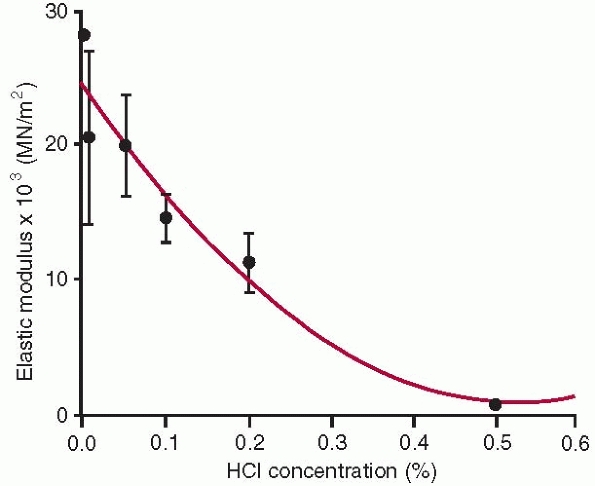

the lowest level of the structure consists of single collagen fibrils

with embedded apatite crystals. At this level of structure, changing

the collagen to mineral ratio has a significant effect on the elastic

modulus of bone,30,32,42 because it decreases with loss of mineral (Fig. 1-13).

This is important from a fracture healing perspective because

mineralizing healing callus goes through phases of increasing mineral

density and corresponding increased modulus as healing occurs. At the

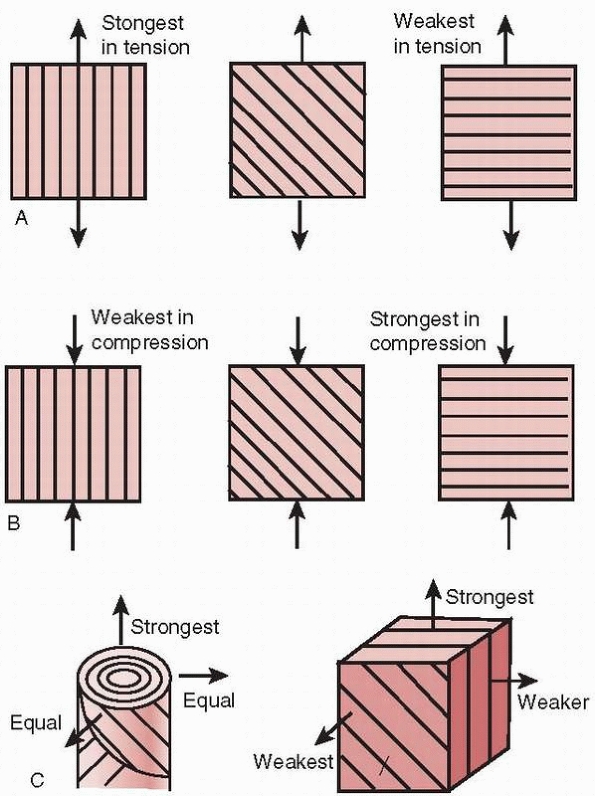

next level of structural organization, the orientation of the collagen

fibrils is important.9,10,11,12,55,56,57 As demonstrated in Figure 1-14, the orientation of its fibers affects the ability of bone to support loads in specific

directions. During fracture healing, the callus initially starts as a

disorganized random array of fibers, which progressively reorganize to

become stiffest along the directions of the major applied loads (body

weight and muscle forces) to which the bone is exposed. At the next

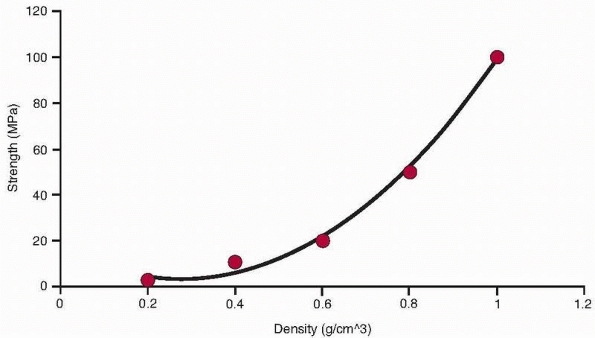

level, the density of the haversian systems affects bone strength. It

has been repeatedly demonstrated that a power law relationship exists

between bone density and strength at this level of structure (Fig. 1-15).

This means that as bone density decreases, its strength decreases as

the square of its density (as density decreases by half, strength

decreases by a factor of 4). This forms the basis for predicting

changes in bone strength as a result of conditions such as

osteoporosis. Similarly, the modulus changes with bone density by a

power of between 2 and 3.19,21,29,35,62

Noninvasive measures of bone density such as quantitative computed

tomography (qCT) have been shown to have a significant predictive

relationship to bone strength.3,43,44,103

|

|

FIGURE 1-13

Elastic modulus of bone samples tested in tension after exposure to different concentrations of HCl. Greater HCl concentration progressively demineralizes bone, ultimately leaving only collagen. This diagram illustrates the contribution of bone mineral to the tensile elastic modulus of whole bone.30 |

|

|

FIGURE 1-14 Effects of collagen fiber direction on the resistance to loads applied in different directions. A. Under tensile loading, the strongest arrangement is having the collagen fibers parallel to the load. B. Under compressive loading, the strongest arrangement is having the collagen fibers perpendicular to the load. C.

In bone that must accommodate different loading directions, the arrangement of the haversian system produces one strongest direction along the axis, with proximately equal strengths in other directions.57 |

bone. As discussed previously, bone is a viscoelastic material whose

strength and modulus both increase as loading rate increases (for

example, in fracture impact loading as compared with normal ambulation).29,38,39,40,108,163

The geometry of bone, specifically the size of the cross section and

thickness of the cortex, affects its moment of inertia and therefore

its strength.124 Age also affects

bone properties. The bending strength and modulus increase as bone

mineralizes and matures from childhood to adulthood and slowly decrease

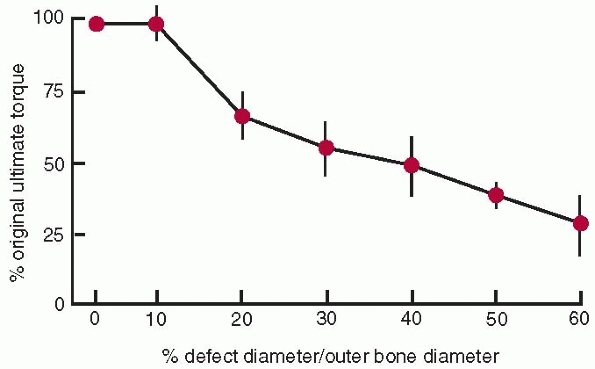

thereafter39,43,157 and the capacity to absorb impact energy decreases with age41 as bone becomes more brittle. Defects or holes in bone (for example from drilling for screws) also affect its strength.27,30,47,97,106 The torsional strength of bone decreases as the diameter of the hole or defect increases (Fig. 1-16).

As the hole increases in size to 30% of the diameter of the bone, bone

strength decreases to about 50% of that of the bone without a defect.

An important consideration, applicable in the resection of bone (such

as in removal of a tumor) is the shape of the hole or defect left after

tumor removal. Leaving a hole with square corners significantly

decreases bone strength compared to the same hole with rounded corners,

because the square corner is a large stress concentrator. Oval or

circular holes, while themselves still stress risers, do not contribute

the additional effect of the sharp corner.34 Table 1-3 summarizes the strength of cortical and cancellous bone material as well as the ultimate strengths of various whole bones.

in its mineral content, callus diameter, and fiber organization, as

discussed previously. The initial callus forms from the periosteal

surface outward, which is beneficial mechanically, because as the outer

diameter of the healing area enlarges, its moment of inertia and

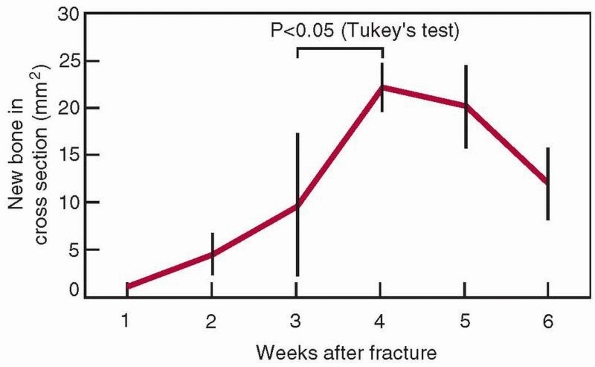

therefore its initial stiffness both increase, as shown in Figure 1-17.122 The cross-sectional area increases progressively, as shown in Figure 1-18, as does the mineral content of the callus.8 The mechanical results of these changes to bone as the fracture heals are shown in Figure 1-19.

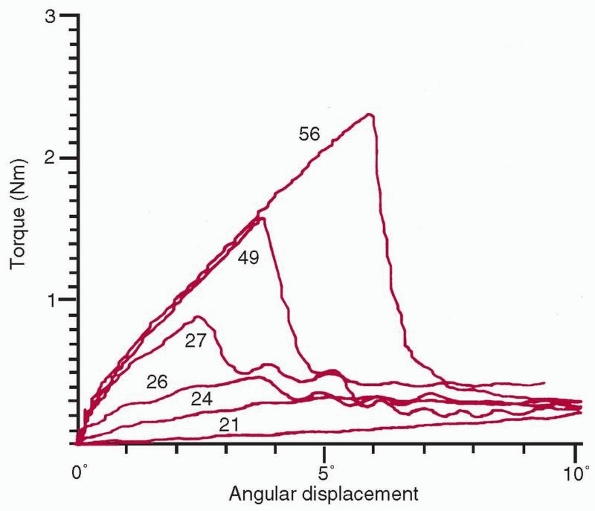

From torsional tests of healing rabbit long bones, progressive

increases were observed in stiffness and peak torque to failure with

time.159 Interestingly, in that

experiment, the stiffness appeared to gain normal values before the

peak torque to failure, showing that stiffness and strength are related

but not directly. Figure 1-19 shows that beyond 4 weeks (in rats, whose bones heal rapidly),

the cross-sectional area starts to decrease as the bone remodels to normal shape, while the bone tissue continues to mineralize.

|

|

FIGURE 1-15

The relationship of trabecular bone density to compressive strength and modulus demonstrates a power law relationship so that these properties decrease by a factor of about 4 when density decreases by half.32 |

system along with the available blood supply affects the type of tissue

formed in a healing fracture. The theory of interfragmentary strain

attempts to relate the types of tissues formed to the amount of strain

experienced by the tissue between the healing bone fragments.122

This theory is a simple representation and cannot describe the complex

stresses that the tissue is exposed to during actual healing.

Nonetheless, within the limitations of the theory, when large strains

occur in the tissues between healing bone surfaces, granulation tissue

is formed. Intermediate level strains produce cartilage and small

strains result in primary bone healing, or direct deposition of bone

tissue with limited callus formation.

|

|

FIGURE 1-16

The relationship of ultimate torque (failure torque) of a long bone to the diameter of the hole divided by the outer diameter of the bone. There is no change in ultimate torque until the defect size increase beyond greater than 10% of the diameter of the bone.47 |

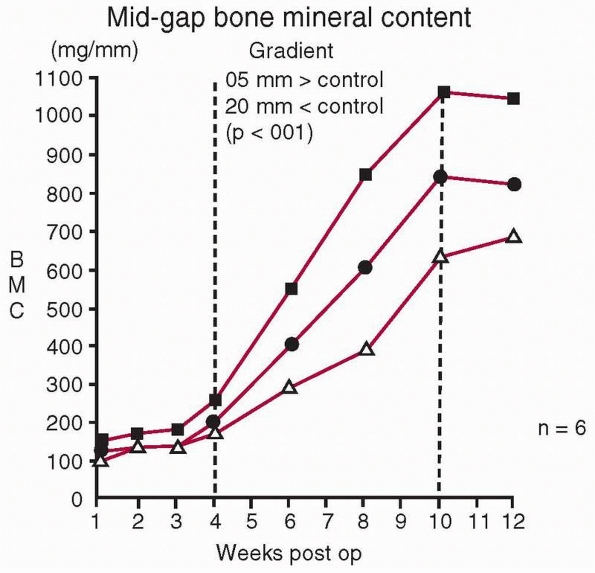

recognize that it doesn’t follow that zero strain will result in

maximum bone formation. Load and some resulting strain are necessary

within the healing fracture to stimulate bone formation. In a study in

which controlled daily displacements in compression were applied to

healing long bones using an external fixator, and the bone mineral

within the healing fracture was measured with time, there was an

optimal displacement above or below which less mineral was created in

the fracture callus (Fig. 1-20).158 Further, compression rather than tension is the preferred direction of loading.16

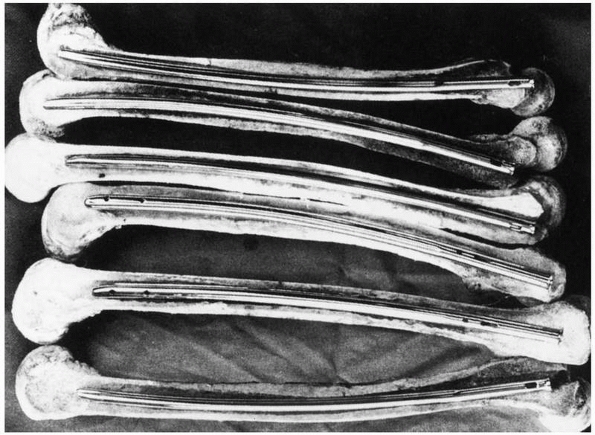

Fracture fixation constructs of different stiffnesses within a certain

range produce healed fractures with similar mechanical properties,

however, they may reach this endpoint by different routes. In a study

of femoral fixation using intramedullary rods of either 5% or 50% of

the torsional stiffness of the intact femur, the femurs fixed with the

lower stiffness rods produced an abundance of stabilizing callus, as

opposed to the femurs with more rigid fixation, see Figure 1-21.

This is because with more rigid fixation there was less necessity for

biological fracture stabilization. In both cases, however, the

mechanical properties of the healed fractures were ultimately similar.162

These studies demonstrate that some strain as a result of loading the

fracture stimulates healing, and that bone will adapt and heal within a

relatively wide range of mechanical stability environments.

and healing fractures. Increasing mineral content increases fracture

stiffness. Callus that forms on the periosteal surface is beneficial in

increasing the moment of inertia and therefore the stiffness of the

fractured region. Healing fractures exhibit several stages, with

stiffness returning to normal followed later by peak load to failure.

Bone will heal within a range of mechanical environments. To a certain

extent, healing bone will compensate for more flexible fixation by

forming a greater quantity of fracture callus; however, there is a

range of loading of a healing callus, sufficient to stimulate bone

formation, which increases as the callus matures.

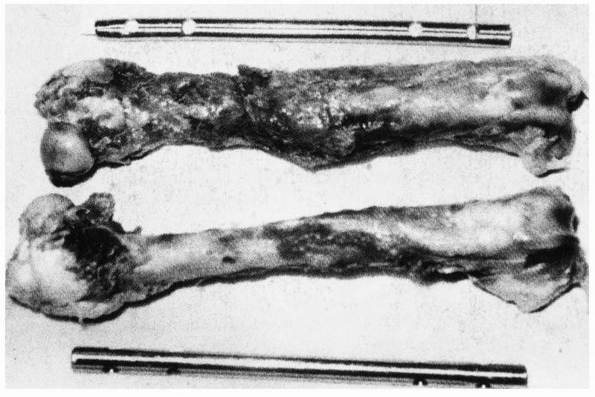

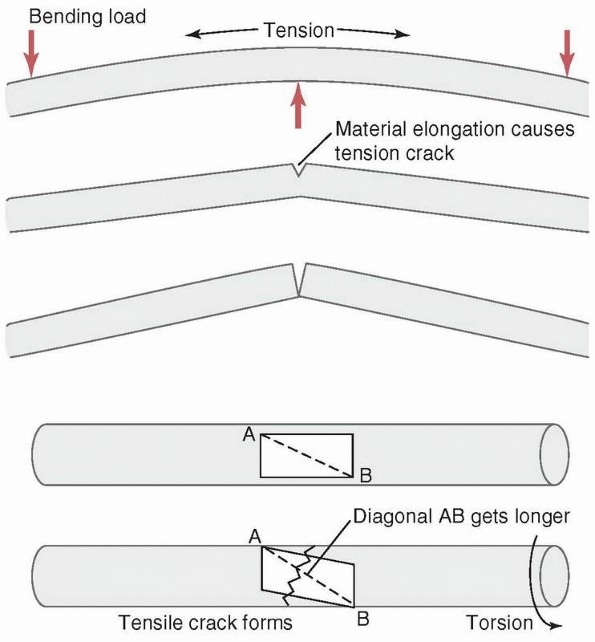

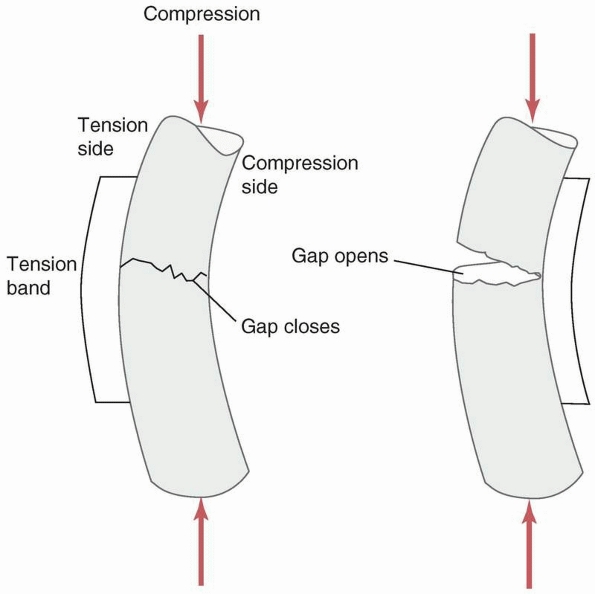

tension and strongest in compression. Therefore, when a force creates

tensile stresses in a particular region of a loaded bone, failure will

generally occur first in that region. The simplest example, shown in Figure 1-22,

is the transverse fracture created in a long bone subjected to pure

bending. Because in this example the upper, convex surface undergoes

the greatest elongation, it is subjected to the largest tensile

stresses, and failure, indicated by a crack, initiates here. The crack

then progresses transversely through the material, and layers just

below the outer layer become subjected to high tensile stress until

they crack as well. In this manner, the crack progresses through the

bone transversely until it fails. The concave surface is subjected to

compression so the crack does not initiate there. A second example is

the fracture line or crack that occurs when a bone is subjected to

torsion or axial twisting. In those cases, a spiral fracture results.

Consider, as shown in Figure 1-22, a

rectangular area on the surface of a long bone that is loaded in

torsion. The rectangle distorts as the bone twists, with one diagonal

of the rectangle elongating and the other shortening, depending on the

direction of twist. A crack will form perpendicular to the diagonal

that is elongating, and progresses around the perimeter of the bone

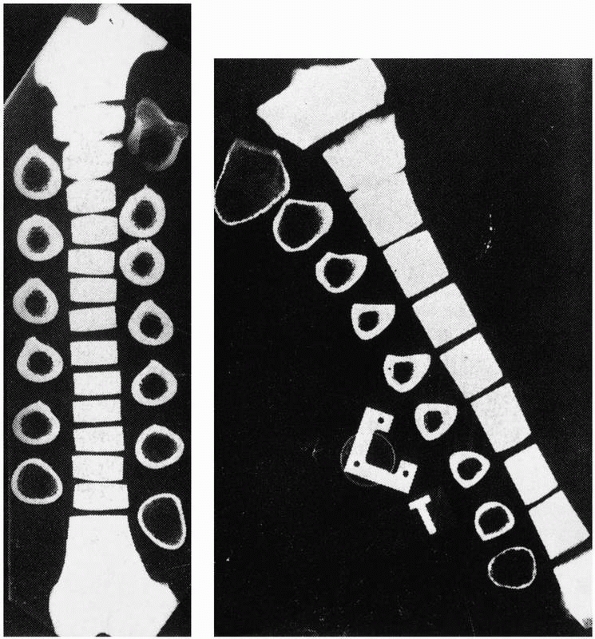

resulting in a spiral fracture. The region of bone with the smallest

diameter is usually the least stiff region, resulting in the greatest

distortion of the surface and is generally the location of the

fracture. This explains why torsional fractures of the tibia often

occur in the narrow distal third, see Figure 1-23.

|

TABLE 1-3 Mechanical Properties of Bone Material and Whole Bones in Different Loading Directions

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

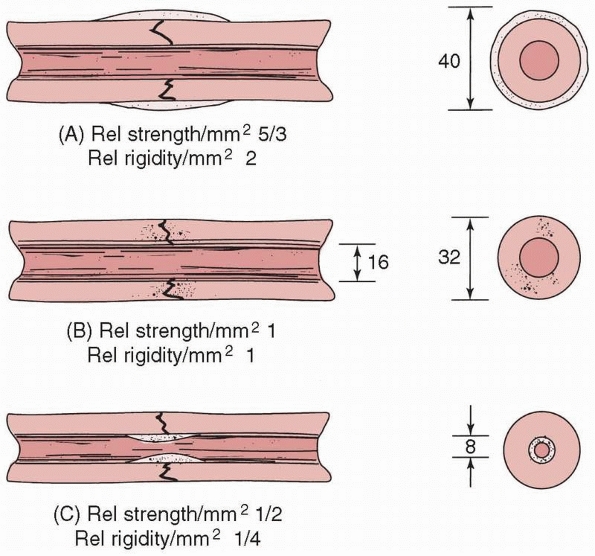

FIGURE 1-17 A comparison of the moments of inertia and resulting strengths when fracture callus is located (A) on the outer surface, (B) on the bone surfaces, or (C)

in the medullary canal. The strength and rigidity are significantly increased when callus is located over the periosteal surface, compared to within the medullary canal.118 |

|

|

FIGURE 1-18

Changes in the cross-sectional area of a healing femoral fracture, which peaks and slowly decreases. There is a similar increase in the mineral content. (The data come from rats, which heal more rapidly than humans, indicated by the 4-week time to peak mineralization.8) |

|

|

FIGURE 1-19

A comparison of superimposed torque-angular displacement plots taken from experimental long bones at different stages of healing shows the significant increase in both stiffness and peak torque to failure with increased duration of healing. Numerical values are time in days postfracture in rabbits.159 |

|

|

FIGURE 1-20

The effect on bone mineral of different cyclic displacements applied daily within a healing fracture (upper curve, 0.5 mm; middle curve, 1.0 mm; lower curve, 2.0 mm for 500 cycles/day). This shows that some displacement (in this experiment, 0.5 mm) stimulates bone formation, but that greater displacements (1.0 mm and 2.0 mm) do not enhance bone formation. These results point to an optimal range of displacements for maximum bone formation.158 |

|

|

FIGURE 1-21 A comparison of the different healing responses of dog femurs with midshaft fractures fixed with (top) IM rods of 5%, or (bottom)

50% of the torsional stiffness of the intact femur. The femurs fixed with rods of lower stiffness produced more callus as additional stabilization against functional loads, but there was ultimately no difference in mechanical properties between the femurs fixed with rods of different stiffnesses.162 |

|

|

FIGURE 1-22 Top:

A transverse fracture is created by the progressive tensile failure of bone material starting from the convex surface in which elongation and therefore stress is greatest, with the crack progressing to the concave side. Bottom: A spiral fracture is created by the progressive failure in tension of fibers on the bone surface along the diagonal that elongates as the material on the surface distorts when torque is applied. (A rectangle on the surface becomes a parallelogram, with one diagonal elongating. The crack will be transverse to the diagonal.) |

|

|

FIGURE 1-23 Cross sections through (left) a femur, and (right)

a tibia. The small cross section of the distal third of the tibia results in more distortion and higher stresses and explains why torsional failure often occurs in this area. |

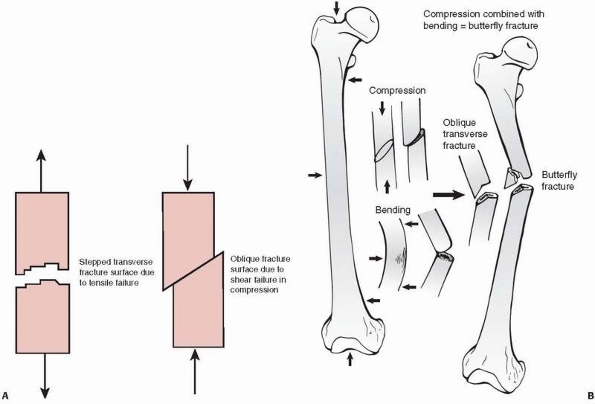

by shear, indicated by slippage along the diagonal, because bone is

weaker in shear than in compression (Fig. 1-24).

In this case, compressive loading causes an interface within the bone

at 45 degrees to the applied load to slide along another at an oblique

angle. At very high loads, such as during impact fractures, crushing or

comminution of bone also occurs, especially at the weaker metaphyseal

ends of a long bone. The trabecular bone at the metaphyseal ends is

weaker in compression than the diaphyseal cortical bone is in shear.

Because of this, it is unlikely that shearing failure will occur in the

diaphysis caused by pure compressive forces. The butterfly fracture (Fig. 1-24)

results from combined bending and compression. Bending load causes the

fracture to start to fail in tension producing a transverse crack, but

as the crack progresses and the remaining intact bone weakens, it

starts to fail in compression, causing an oblique (shear) fracture

line. As the ends of the failing bone are driven together, a third

fragment—the butterfly—may result as the

oblique

fragment splits off. The production of a butterfly fragment probably

depends on the timing and magnitude of the two basic applied loads:

compression and bending.

|

|

FIGURE 1-24 A. Left:

Tensile fracture causes a stepped surface as fibers pull apart. The crack progresses, then steps to an adjacent region in which failure continues. Right: Pure compression of cortical bone results in failure by shearing or sliding along oblique surfaces. In reality, pure compression of a long bone (in a fall for example) results in crushing of the much weaker metaphyseal trabecular bone with a pilon fracture of the distal tibia or a tibial plateau fracture as the result. B. Some fractures that combine bending and compression demonstrate transverse cracking as a result of bending followed by an oblique crack characteristic of compressive failure. The butterfly fracture with additional splitting of the fragment secondary to the initial fracture is an example. |

force required to fracture bone and the types of fractures that occur.

As shown in Figure 1-15, trabecular bone

stiffness varies with the cube (3rd power) of its density and strength

approximately with the square of its density.32

Bone mass normally peaks around age 25 to 30 years and decreases up to

1% annually thereafter. If the density of trabecular bone is decreased

by 30% in a 60- to 70-year-old as a result of osteoporosis, the bone

compressive strength is about half of that of a 30-year-old. Typically,

fractures as a result of osteoporosis occur in the vertebrae, the

distal radius, and the femoral neck. In addition, osteoporosis changes

the cross-sectional shape of long bones, decreasing thickness by

increasing the endosteal diameter while causing the periosteal diameter

to increase. If cortical outer diameter—for example, in the

femur—increased and cortical thickness decreased at the same rate, the

moment of inertia of the bone cross section would be larger. That is

why large-diameter thin tubing can be substituted for smaller diameter

thicker tubing in structures (for example, sailboat masts), saving

weight while not sacrificing strength. However, in the femur, the inner

surface of the cortex also becomes more irregular and porous,

decreasing its material strength. A common result of loss of femoral

bone mass combined with other factors, such as poor balance, is a hip

fracture usually resulting from a fall.1

mechanisms have been observed. Fracture of the calcaneus or the

malleoli of the foot and ankle can occur through a combination of the

foot being forced against the brake pedal by the weight of the occupant

during a high speed frontal collision, or in combination with the floor

pan of the auto crushing into the space in which the foot resides.127

Drivers who were braking during a crash were shown to be much more

likely to injure their right foot compared with their left foot.15

If the Achilles tendon applies load to resist the forced dorsiflexion

of the foot on the brake pedal, the combination of these two loads make

cause three point bending loading of the calcaneus, with the posterior

facet of the talus as the fulcrum. A crack initiates on the plantar or

tensile side of the calcaneus and a tongue type calcaneus fracture can

occur. Inversion or eversion, in which the foot is not securely planted

on the brake pedal and rotates with compression, is likely to result in

a malleolar fracture,61

although the combinations of forces causing these high energy fractures are not entirely predictable.

with the dashboard of the vehicle in a frontal collision, especially

for unrestrained drivers who submarine or slide forward in the seat.154 Tensing the quadriceps and hamstrings muscles during a crash applies significant additional compression along the femur.154

The anterior bow of the femur causes the external compressive force

from contact of the knee with the dashboard, and internal muscle forces

to bend the femur, resulting in bending and transverse or oblique

fractures. If the femur of the occupant hits the dashboard in an

adducted orientation, the femur can be displaced from the acetabulum,

causing a fracture of the acetabular roof and dislocation of the hip

joint. Pelvic fractures result from loading in side impact crashes, in

which the door punches inward against the hip and pelvis. The actual

fracture pattern (symphysis, sacroiliac joint, or both) is probably the

result of the specific alignment of the pelvis with the applied loads

at impact. Pelvic fracture classifications are based on the presumed

mechanism of injury and specific forces applied.139,141,166,167

Bilateral hip fractures have been found to occur in crashes in which

the vehicle has a large center console that tends to trap the pelvis as

force is also applied on the hip opposite that which contacts the door.

Auto crashes also create, in occupants with lap but not shoulder belts,

the classic “Chance fracture,” which is combined compression and

flexion failure of a lumbar vertebra, usually at the level in which the

lap belt forms a fulcrum. Upper extremity injuries in auto crashes have

been found to be related to airbag deployment and entrapment of the arm

in the steering wheel.65

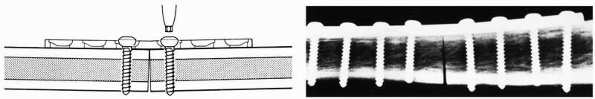

devices for skeletal fracture fixation are discussed. Observed fixation

problems with devices such as wire, cable, screws plates, IM rods, and

external fixators are explained with the objective of reducing the

potential for mechanical damage or failure of these devices during use.

However, solid wire is very sensitive to notches or scratches. Testing

shows that notches as small as 1% of the diameter of the wire can

reduce its fatigue life by 63%.132

For this reason, cable has been introduced for cerclage applications.

Cable has significantly better fatigue performance compared to wire, as

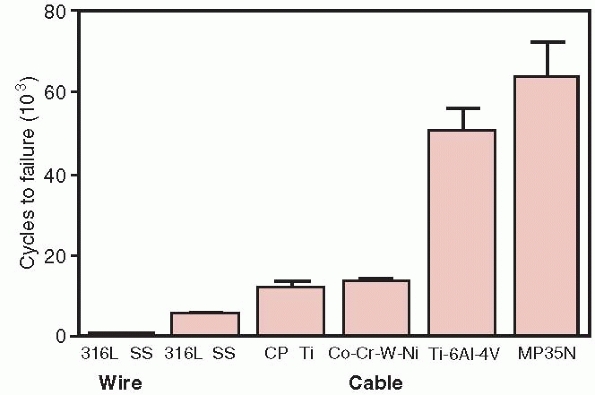

shown in Figure 1-25.64

Because cables consist of multiple strands of single thin wires, damage

to any particular strand does not result in failure of the whole cable.

Single loops of suture such as Ethibond are about 30% as strong as

18-gage stainless steel wire in tension, and Merseline tape is about

50% as strong. Four loops of Ethibond were shown to have tensile

strength equivalent to stainless steel wire.70

|

|

FIGURE 1-25

A comparison of the fatigue resistance of wire and cables made of the indicated materials. Wire, 316 SS (stainless steel), cable 316 SS, Cp Ti, commercially pure titanium, Co-Cr-W-Ni, cobalt chrome, Ti 6Al 4V, titanium alloy, MP35N, nickel alloy.64 |

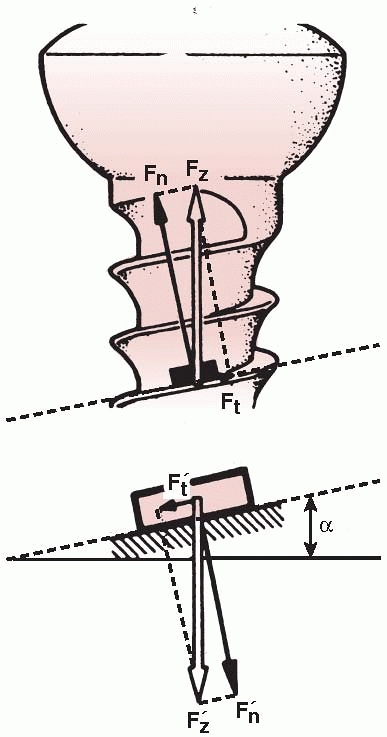

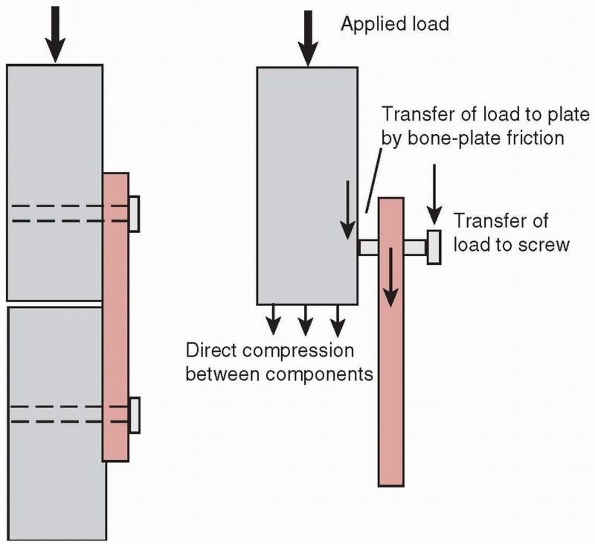

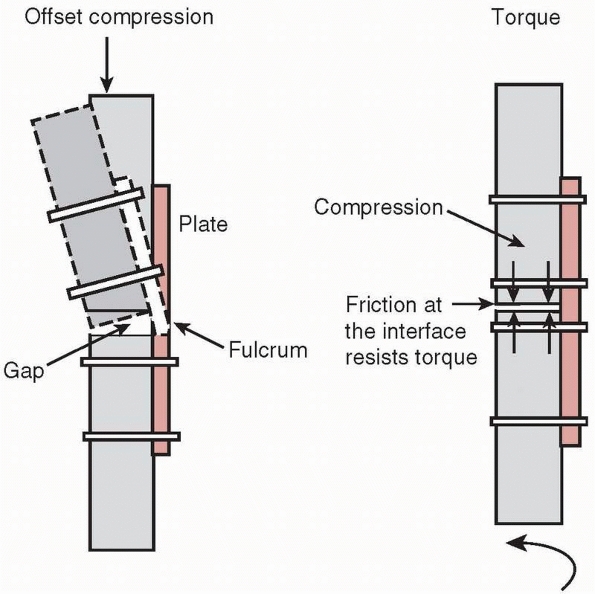

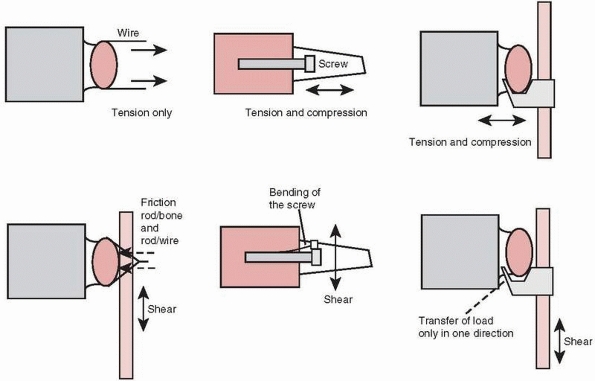

rotary load (torque) into compression between a plate and bone, or

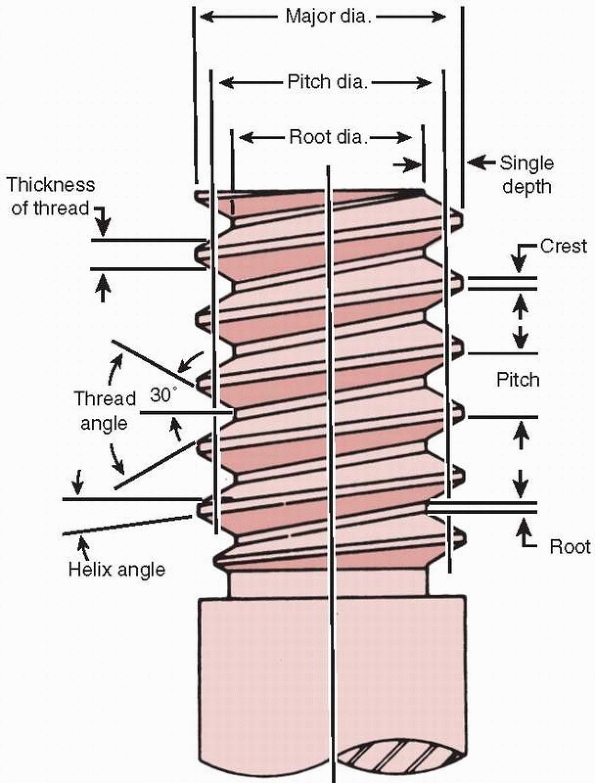

between bone fragments. As shown in Figure 1-26,

the thread of a screw, if unwound from the shaft, is really a ramp or

inclined plane that pulls, for example, underlying bone toward

the fixation plate, causing compression between them.123 The basic components of a screw are shown in Figure 1-27.

Because of its function, the screw head and shaft should be free to

turn in the plate; otherwise the compressive force generated may be

limited. (This doesn’t apply to screws that are designed to be threaded

into the plate holes in locking plates.) One common problem is that

sometimes threads are tapped into both bone components. The bone

component in which the screw head will rest should be drilled oversize

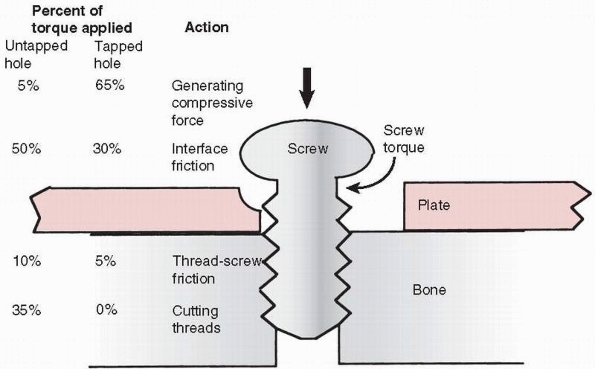

to allow the shaft of the screw to turn freely. Tapping is necessary in

cortical bone so that the torque applied by the surgeon is converted

into compression instead of cutting threads and overcoming friction

between the screw thread and bone (Ft in Figure 1-26) that it is being driven into (Fig. 1-28).75

At the same time, self-tapping screws are available and, when used,

those with multiple cutting flutes at the tip of the screw appeared to

be the easiest to insert and had greater holding power.165

With cancellous bone, as discussed later, tapping is less advantageous,

unless the bone is very dense. One common problem during screw

placement is shear failure of the screw, typically the head twisting

off leaving the shaft embedded in bone and difficult to remove. This

can occur especially when using smaller (less than 4 mm diameter)

screws in dense bone, especially without tapping. The stiffness and

strength of a screw are related to the 4th power of its diameter (the

effect of moment of inertia, for screws of the same material). A 6-mm

diameter screw is approximately 5 times as stiff as a 3-mm diameter

screw and 16 times as resistant to shear failure by over-torquing the

screw during insertion.

|

|

FIGURE 1-26

A screw is a mechanical device that converts torque into compression between objects. The screw thread is actually an inclined plane that slowly pulls the objects it is embedded into together. For this reason, the head and screw shaft in one part must be free to rotate. If this part of the screw is threaded into the hole of the first part (for example, the plate) it will not allow the surfaces to compress (Fn, normal or compressive force acting against the screw head; Ft, tangential or frictional force acting along the screw thread; Fz, resultant of the two forces, α, angle of the screw thread. The smaller the angle α [finer thread] the lower the frictional force). |

|

|

FIGURE 1-27

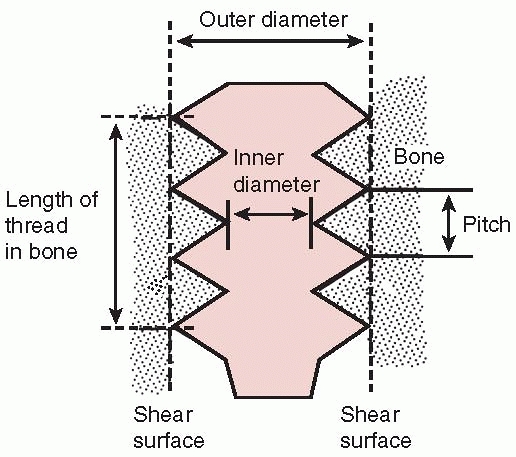

Nomenclature of screws. The root diameter is the inner diameter of the screw and the pitch defines the distance between threads. |

|

|

FIGURE 1-28

Schematic diagram showing the approximate distribution of torque acting on screw placed into cortical bone. With a pretapped hole, about 65% of the applied torque goes to produce compression and 35% to overcome the friction associated with driving the screw. When the hole is not tapped, only about 5% of the torque is used to produce compression, the rest going to overcome friction and to cut threads in bone. These observations do not apply in cancellous bone. |

a screw can withstand along its axis, the pullout force, depends upon

the size of the screw and the density of the bone it is placed into. As

shown in Figure 1-29, when the force acting on

the screw exceeds its pullout strength, the screw will pull or shear

out of the hole, carrying the sheared bone within its threads, because

it is usually the bone that fails and not the screw. The pullout force

increases with larger screw diameter, a longer embedded length of screw

shaft, and greater density of the bone it is placed into.33,45,58,134

The diameter and length of the embedded screw can be thought of as

defining the outer surface of a cylinder along which the screw shears.

Given the maximum stress that bone of a particular density can

withstand, increasing the surface area of the screw cylinder increases

the pullout force (because force = stress × area over which it acts).

To enhance screw purchase, consider embedding the largest diameter

screw possible into bone of the greatest density over as long a

purchase length as possible.33,45 Pullout strength also increases significantly if the screw is placed through both bone cortices.

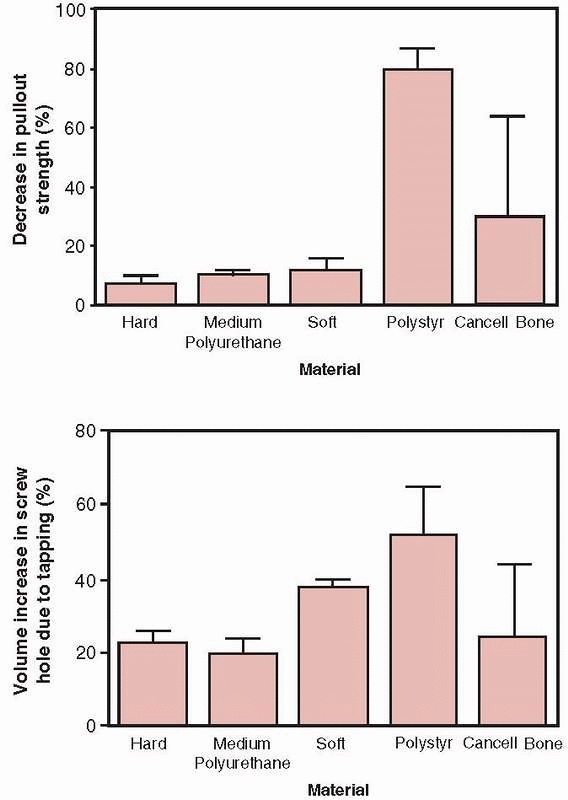

problem because the porosity of cancellous bone reduces its density and therefore its shear strength.148

Hole preparation, specifically drilling but not tapping, improves the

pullout strength of screws placed into cancellous bone (such as pedicle

screws in the vertebral body).33 The reason that tapping reduces strength in cancellous bone, as shown in Figure 1-30,

is that running the tap in and out of the hole removes bone,

effectively increasing the diameter of the hole and reducing the amount

of bone material that interacts with the screw threads. Tapping has

more effect as bone density decreases and can reduce the pullout

strength from 10% to as much as 30%. It should also be noted that the

findings of studies related to pullout strength relate to the time

immediately after insertion. As the bone heals, it also remodels around

the screw, possibly doubling its initial pullout strength.134

|

|

FIGURE 1-29

The factors that determine the pullout strength of a screw are its outer diameter and length of engagement (this defines the dimensions of a cylinder of bone that is carried in the threads and is sheared out as the screw is pulled out of bone) and the shear strength of bone at the screw/bone interface, which is directly related to its density. A finer pitch screw produces a small gain in purchase.33 |

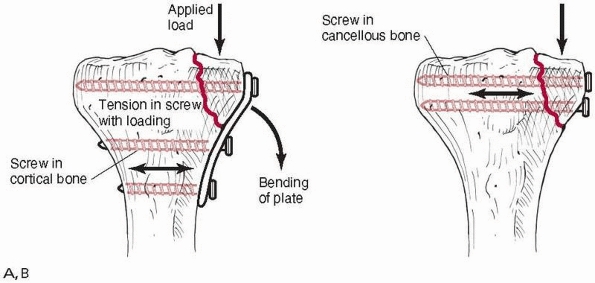

This mode of loading could occur during functional use; for example,

with a dynamic compression plate (DCP) but not a locking plate. The

screw should be tightened against the DCP plate to the maximum extent

possible and the tightening torque effectively transferred to

compressive force between plate and bone (see Fig. 1-28).

The screw holds the plate against bone partly by frictional contact,

which depends on the frictional force generated between the

undersurface of the plate and bone. The frictional force is directly

dependent on the compressive force generated by the screws. If any

sliding occurs between the plate and bone, bending load will be

transferred from the head of the screw into the plate, where

screw-plate contact occurs. Bending loads perpendicular to the axis of

the screw, along with possible stress corrosion and fretting corrosion,

may cause the screws to fail rapidly in fatigue. Zand et al168

showed that screws tightened against a plate with only 10% to 15% less

force than the maximum possible failed in less than 1000 loading

cycles, by bending fatigue, compared with fully tightened screws that

were able to sustain over 2.5 million loading cycles. Screws that lock

into the plate reduce this problem. Small fragment screws, around 4 mm

outside diameter, can fatigue because their core diameters are small.

The trade-off in use of these devices is choosing a screw with a larger

core diameter and shallower thread to reduce the possibility of

fatigue, or a smaller core diameter and deeper thread to increase

purchase strength in bone.111

|

|

FIGURE 1-30 Top:

The decrease in pullout strength in various types of foam used to test bone screws demonstrating the percentage decrease in pullout strength between screws placed into holes that were either drilled only or drilled and tapped. Bottom: The percentage increase in volume comparing holes that were drilled only and those that were drilled and tapped. Tapping in cancellous bone increases hole volume, which decreases pullout strength.33 |

the significant advantage that they can be precisely guided into

position over a guide wire, which itself may aid in reduction of a

fracture fragment. Nevertheless, drilling precision for the screw or

guide wire is decreased with increasing density of bone, and the use of

longer and smaller diameter drill bits.74

Cannulated screws follow the same mechanical principles as solid

screws, however, to create the central hole, material must be removed

from the center of the screw. Manufacturers commonly increase the minor

diameter (the diameter of the screw at the base of the thread) to

accommodate the loss of this material. The same size cannulated screws

usually have less thread depth compared with solid screws. The

result—depending on the screw size—is less pullout strength. For 4-mm

diameter screws, cannulated screws of the same outside diameter had

about 16% less pullout strength.151 Alternatively, to keep the same thread depth, the outer diameter of the screw may be increased.

|

|

FIGURE 1-31

A mechanism for rapid failure of screws in cyclic bending occurs when the screw has not been tightened sufficiently to keep the plate from sliding along the bone surface (the plate-bone gap shown here is exaggerated for clarity). The result is that bending loads are applied transverse to the long axis of the screw, which in combination with fretting corrosion caused by the screws rubbing against the plate results in early failure of the screw. |

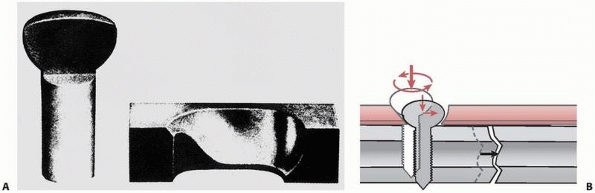

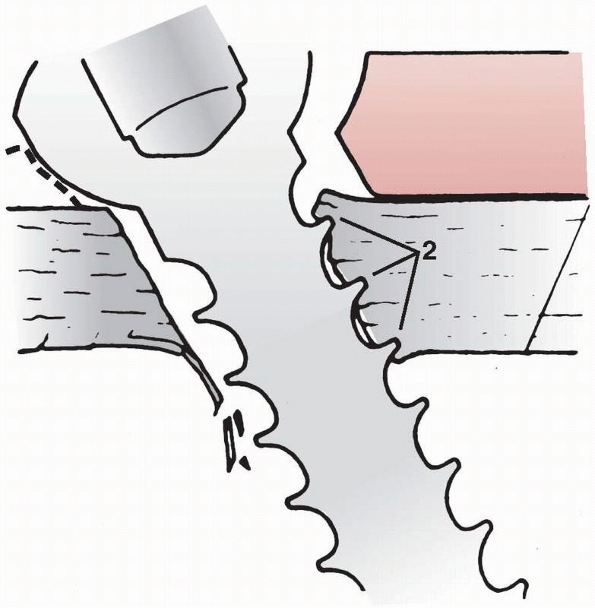

fracture by driving the ends of the fracture together, compressing

them. This is beneficial to fracture healing because it improves

stability, opening the possibility for primary bone healing with

minimal callus formation, and by enhancing the resistance of the plate

to bending fatigue failure. Observing the cross section of an oval hole

in a dynamic compression fracture plate, Figure 1-32,

shows that one border of the hole actually has an inclined surface.

When the head of the screw displaces downward toward the bone surface,

the screw and the fragment of bone it is attached to slide toward the

center of the plate. This action, which occurs in both fracture

components, causes the fracture surfaces to be driven together2 and creates significant compressive forces across the ends of the fracture.37

Compressing the ends of the fracture significantly improves the

stability of the construct and reduces bending and torsional stresses

applied to the plate, increasing its life. Stability is improved

because the bone ends resist bending forces that close the fracture

gap, and torsional loads are resisted by the frictional force and

interlock between the ends of the fracture components. Also, the

fracture gap that must be healed is smaller.

|

|

FIGURE 1-32 A. Cross section through the head of a bone screw and the hole in a fracture plate showing the geometry. B.

As the screw is tightened, the head slides down the inclined border of the plate, which displaces the screw sideways, and therefore the screw and the bone fragment to which the screw is attached are displaced toward the opposite fragment. |

|

|

FIGURE 1-33 Left:

When a gap is left on the cortex opposite that to which the plate is attached, bending of the plate at the fracture site can cause the plate to fail rapidly in bending. Right: Compressing the fracture surfaces not only allows the bone cortices to resist bending loads but the frictional contact and interdigitation help resist torsion. |

vulnerable to bending failure, because plates are thin, relatively easy

to bend (compared to bone), and have low moments of inertia. They are

designed to apply compressive force to the ends of the fracture, and

the stabilized bone can then resist the bending loads applied during

functional use. If a gap is left on the side opposite the plate, Figure 1-33,

the fracture site becomes a fulcrum around which the plate bends under

combined compressive and bending loads such as those which occur during

ambulation (if the compressive force is not located directly down the

tibial

shaft,

which occurs during heel strike and toe off, then bending loads will be

applied along with the compressive force). Gapping can also occur when

a segment of bone is missing at the fracture site, or if the plate is

not properly contoured during application. Figure 1-34

demonstrates how a flat, noncontoured plate tightened against a flat

bone surface will cause a gap to appear on the opposite cortex.118

This is why a plate should be prebent sufficiently to create an initial

gap between it and the bone surface it will be applied to.68,119,136

Gapping at the fracture also occurs when the plate is applied to the

predominantly compressive side instead of the tensile side of a long

bone during functional loading that causes bending. Figure 1-35 demonstrates that placing the plate on the compressive side will cause a gap to open under load.

|

|

FIGURE 1-34

A demonstration of the gapping that occurs on the opposite cortex when a flat plate is applied to a flat bone surface. Slightly prebending the plate causes the ends of the opposite cortices to be driven together when the plate is applied.118 |

In comminuted fractures in which it is difficult to approximate the

fracture ends, screws should be placed as close as possible across the

fracture gap to reduce strains in the plate.53

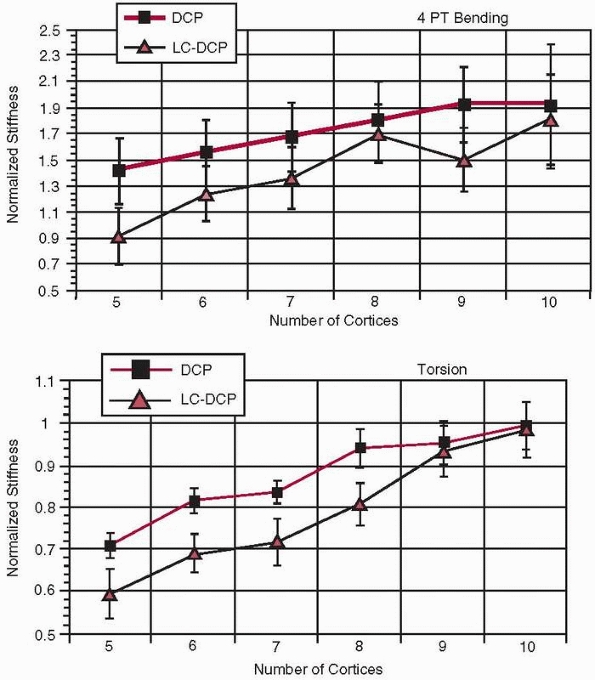

Torsional and bending stiffness of a fracture construct can be

significantly increased, and therefore plate strain reduced, by

increasing the length of the plate itself133 as well as with several cortices of fixation (i.e., screw-cortex contact). However, as shown in Figure 1-36,

there is an optimum number of cortices, eight for DCP plates and nine

for LC-DCP plates, beyond which there is little additional gain in

torsional stiffness54. Figure 1-37

shows several interesting aspects related to plate fixation with

screws. First, plate strains are highest at the two holes adjacent to

the fracture gap and become very small five holes away. Second, this

occurs regardless of whether the screws were placed near the fracture

(locations 2, 3, 4, and 5), far from the fracture (locations 7, 8, 9,

and 10), or were mixed (locations 2, 6, and 9).53 This data also indicates that not all holes of the plate need to be filled with screws to provide similar fixation stiffness.

|

|

FIGURE 1-35

The application of a plate on the compressive as opposed to the tensile side of a bone subjected to bending causes a gap to open on the opposite side of the plate during functional loading. |

in which the screw head has a machine thread, separate from the bone

thread, which locks it to the plate. The screws and plate form a rigid

connection. In addition, the screws have been designed with a finer

thread for unicortical fixation.53

The LISS plate functions differently biomechanically from the dynamic

compression plate (DCP). The DCP plate is compressed against the bone

fragments by the screws and requires bone to plate contact to produce a

stable fracture construct. Buttressing of the opposite cortex is

important in maintaining fracture stability and reducing plate stresses

with the DCP plate. Bending loads applied to the screws in the

nonlocking DCP plate caused the screws to rotate within the plate

resulting in fracture fragment motion, higher plate stresses, and

reduced stability at the fracture site.

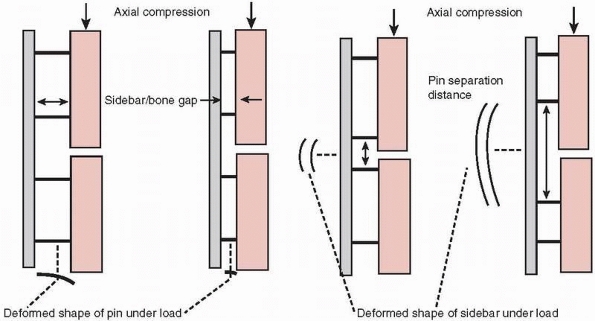

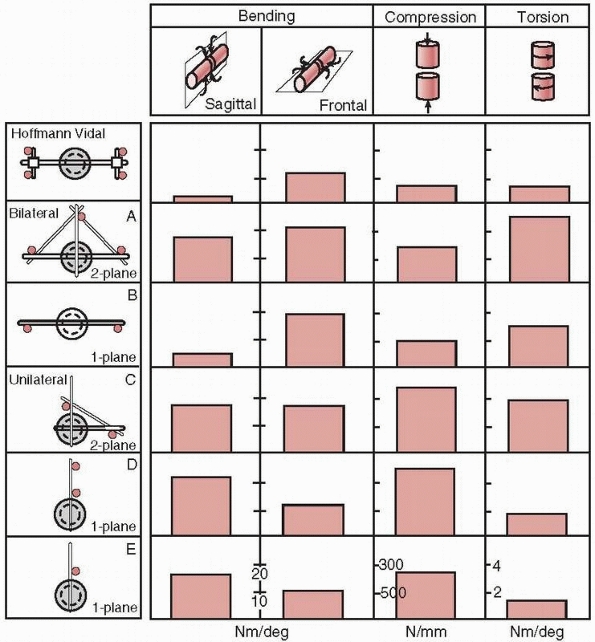

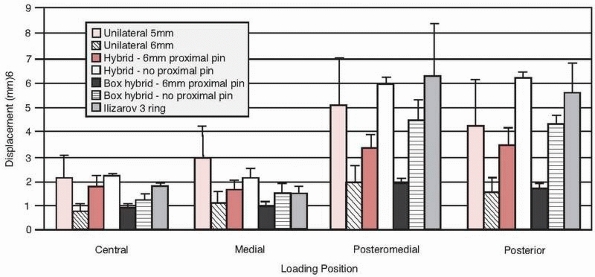

in which the pins (screws) are rigidly connected to the side bar (the

plate) and bone to fixator contact is reduced in the low contact plate

version. This produces less interference with the biological processes

of fracture healing, especially helping to preserve the blood supply

near the fracture site. Also, the LISS plate provides more stability in

comminuted fractures142 in which

cortical buttressing and compression are difficult to achieve and

fracture mechanical stability occurs mainly from the hardware.50

LISS plates do not allow the screws to be directed obliquely, except

when specifically designed into the implant, and do not generally

develop interfragmentary compression at the fracture site. Bending

loads applied to the screws from bone are resisted by the locking

interface between the threads in the screw head and the threads in the

plate. Therefore, these plates are not as dependent on cortical

buttressing for stability as the DCP plate. Dynamic fatigue testing has

shown that LISS plates have fatigue strengths similar to other systems

and are able to support loads comparable to 1 bodyweight for 2 million

cycles, which should be sufficient for normal fracture healing. Because

screw

pullout strength is related directly to the length of screw purchase in

bone cortex, the unicortical screws used in some systems have lower

pullout strength than bicortical screws. More screws must be used to

compensate for the inherent lower pullout strength of the unicortical

screw. As with other systems, the LISS plates have mechanical

sensitivities. For example, accurate placement of the locking screws is

important. As Figure 1-38

shows, angulation of the screw causes incomplete engagement and,

therefore, lower mechanical stability of the construct. In fact,

comparatively, the bending stability of a 4.5-mm LISS plate was reduced

to 63% and 31%, respectively, caused by a 5- or 10-degree misalignment

of the locking screws in the plate.81

|

|

FIGURE 1-36 Relative stiffness of a plate-bone construct in (top) torsion and (bottom)

bending as a function of the number of cortices through which screws have been placed (DCP, dynamic compression plate, LC-DCP, limited contact dynamic compression plate).54 |

|

|

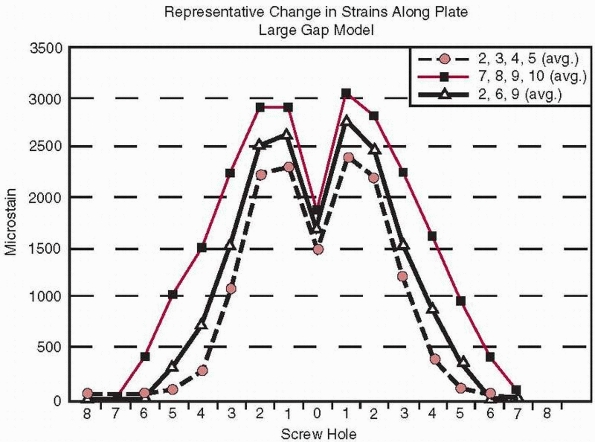

FIGURE 1-37 Distribution of strain (measured in microstrain or strain × 10-6)

at various locations along a plate regardless of placement of the screws in different locations (holes 2, 3, 45), (holes 7, 8, 9, 10), or holes (2, 6, 9).53 |

|

|

FIGURE 1-38 A demonstration of the importance of accurate placement of locking screws into the plate.81

|

provide flexibility of fixation of bone fractures with complex

geometries. It is not necessary to place screws in every hole in the

plate,46 but the effects of screw

placement on fixation stiffness should be understood. The screw hole

will be an area of elevated stresses on the plate, unless the plate is

made thicker near the holes to compensate, as is the case with some

plates. Placing the plate so that an empty screw hole is located over

the fracture will significantly increase the potential for fatigue

fracture of the plate. The plate material around the holes will have

higher material stresses than occurs in the solid regions of the plate.

Around the holes, the force acts through a smaller cross-sectional

area, so the material stresses must be higher. A second consideration

related to multihole plates is that separating the screws so that there

is a greater distance between them across the fracture site results in

lower stiffness of the plate-fracture construct. As with any beam

(plate), the greater the distance between the supports (screws), the

greater the bending displacement and the higher the stresses will be

for the same applied load. It is best to avoid placing screw holes over

or near the fracture site and it is beneficial, in terms of improving

fixation stiffness, to place screws as close together across the

fracture site as possible.

large compressive forces across fracture fragments, and these forces

are applied directly across the fracture site. The head and upper part

of the shaft of the screw must be allowed to glide in one fracture

component so that it pulls the other fracture component towards it to

create compression across the two. As shown in Figure 1-39,

a fully threaded lag screw blocks the gliding action between the two

components. Comparing the compressive forces across the fracture site

using fully and partly threaded lag screws demonstrated that the

average compressive force at the opposite cortex (i.e., the force in

the screw itself) was about 50% greater when a partly threaded screw

was used.86

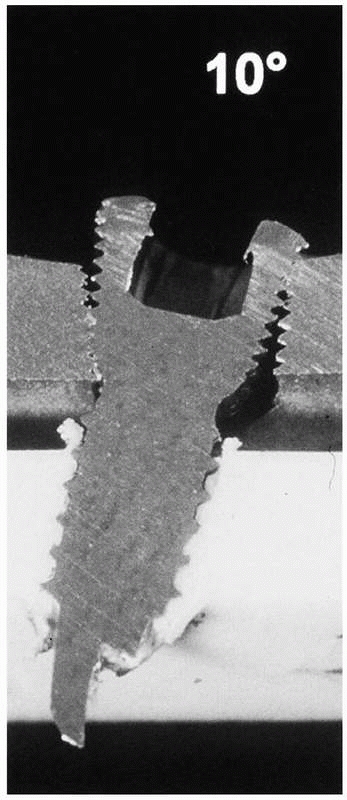

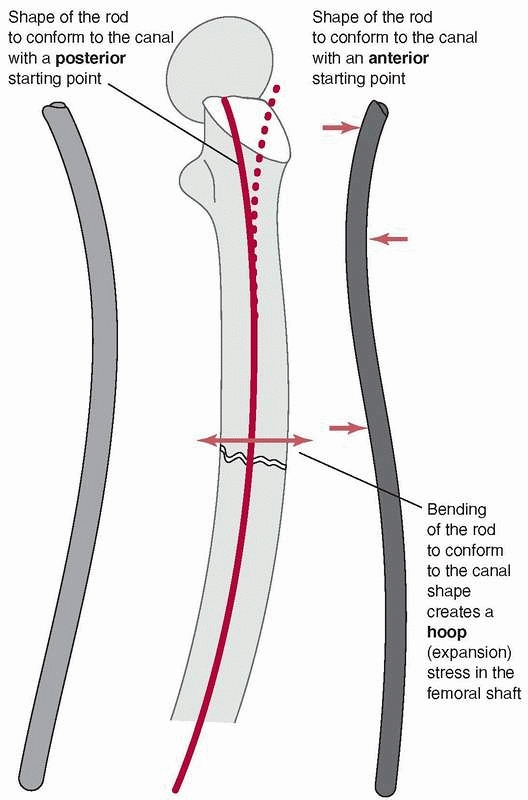

can lead to difficulties because the femur has a significant anterior

curvature,169 shown in Figure 1-40.

Current femoral nails have radii of curvature that range from 186 to

300 cm, compared with the average for a large sample of femora, which

was 120 +/- 36 cm. Therefore, current femoral nails are considerably

straighter than the femora they are inserted into.49

The rod, which also has a curved shape to accommodate the femoral bow,

must conform to the curvature of the femur as insertion progresses.

Placing a rod, which is essentially a steel curved spring, down the

femoral canal causes the rod to bend, because the femur is generally

much stiffer than the rod, Figure 1-41. In fact, the nail must conform not only to an anterior-posterior

bow but also canal curvature medially and laterally.51 Figure 1-42

demonstrates that rod contact with the internal surfaces of the femur

generates forces which resist insertion. These rodfemur contact forces,

directed perpendicular to the surface of the medullary canal cause the

femur to expand and will result in splitting if they become too large.80

|

|

FIGURE 1-39

Using a fully threaded lag screw causes the threads to engage in bone on both sides of the fracture. This inhibits the screw from compressing the bone fragments together.86 |

|

|

FIGURE 1-40 Cross sections of various femora demonstrate the curvature that an IM rod must conform to when it is fully inserted.169

|

|

|

FIGURE 1-41

Mismatch of the curvature between the IM rod and the medullary canal results in bending stresses that could cause splitting of the femur during insertion.80 |

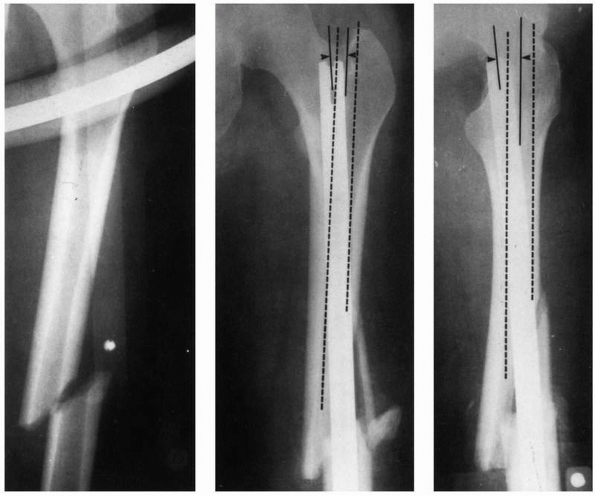

during insertion and the resulting internal forces acting within the

femur are the proximal starting hole position, the length of the

proximal fragment, the initial curvature of the IM rod compared with

the curvature of the femur, and the rod bending stiffness. Stiffnesses

of rods can vary considerably.131 Figure 1-42 demonstrates examples in which rod proximal starting hole position resulted in femoral splitting during rod insertion.80 Some newer IM nails employ a valgus bend to be used with a femoral trochanteric entry portal.120

The optimal entry point for retrograde nailing, used selectively when

antegrade nailing is not possible, was found to be about 1.2 cm

anterior to the femoral origin of the posterior cruciate ligament and

at the midpoint of the intracondylar sulcus.91

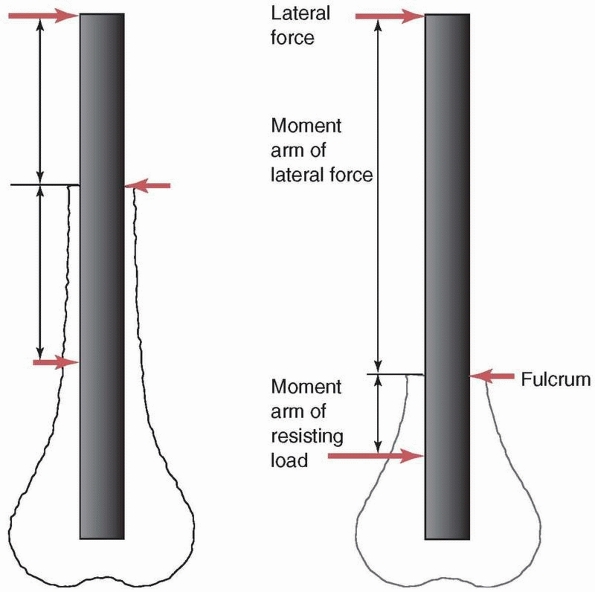

occasionally during healing. The most demanding mechanical situation

for IM rod fixation of the femur or tibia occurs when the fracture is

very distal. Figure 1-43 compares the forces

acting on idealized femora with more proximal and more distal

fractures. For a specific location of the external load (muscle load or

body weight), the more distal fracture results in a longer moment arm

(the perpendicular distance from the load to the fracture site)

creating a greater moment, and therefore higher stresses in the rod.

The highest stresses in the rod occur near the fracture site. With a

distal fracture, in addition to the greater moment, the locking

holes—which are significant stress risers—are usually located just

distal to the fracture site. It has been shown that the maximum

stresses acting in the rod increase rapidly once the distance between

the fracture and the most superior of the distal screw holes is reduced

to less than about 4 cm.28 Cyclic

loading of nails used to fixed distal fractures, with peak loading of

about 1 times bodyweight, confirm that titanium alloy nails can survive

more than 1 million loading cycles when the more proximal of the distal

locking screws is more than 3 cm from the fracture site.7

In addition, placing the distal locking screws can be difficult because

they must be inserted freehand under fluoroscopic guidance. Sometimes

the corner of the screw hole of the rod can be nicked by the drill or

while driving the screw, creating an additional stress riser that can

accentuate the fatigue process. Awareness of these potential problems

has led to design changes such as closing the proximal section of the

rod, increasing material thickness around the screw holes, and cold

forming, which increases the strength of the rod material.

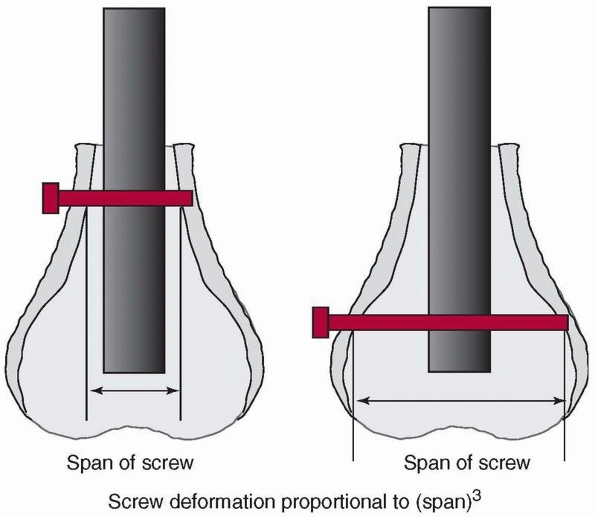

screws are placed into bone with relatively low bone density, the screw

is supported mostly by the cortices. The distal end of the femur widens

rapidly (Fig. 1-44), so the unsupported length

of the screw between the cortices can be quite variable. For the same

diameter and material, the stiffness and strength of a screw subjected

to bending decreases with the third power of its unsupported length

(the distance between cortices, assuming no support from the trabecular

bone). If the unsupported length of one screw is twice as long as that

of another, and assuming that the trabecular bone does not contribute

to support of the screw, one can expect the stiffness and strength of

the screw with the longer unsupported length to be 8 times less than

that of the screw with the shorter length between cortical supports,

and therefore the deformation will be 8 times greater under the same

load. This does create a tradeoff in fixation of

these

fractures with respect to screw placement. If the screws are too close

to the fracture, the stresses in the rod increase, while if they are

located within the flair of the metaphysis, with poor trabecular bone,

their unsupported length increases, decreasing stiffness and strength.

The fatigue life of the distal locking screws is directly related to

the diameter of the root of the thread and the resulting moment of

inertia, so it has been proposed to remove the threads to increase

fatigue life by 10 to 100 times.73

|

|

FIGURE 1-42

The starting position selected for rod entry into the medullary canal affects the degree to which it must bend and the internal forces generated in the femur. A starting position offset from the axis of the medullary canal, coupled with a stiff rod and a longer proximal segment that requires the rod to bend more during insertion, generate higher insertion forces and internal femoral forces. In this example of a midshaft femoral fracture (left), the starting hole was selected medial relative to the axis of the medullary canal (middle) and posterior (right). The medullary canal is outlined in dashed lines. Therefore the rod must bend both medially and posteriorly as it is inserted into the canal and has created internal stresses which have split the distal end of the femur.80 |

|

|

FIGURE 1-43 If the same force acts on IM rods placed in femora with more proximal (left) or more distal (right)

fractures, the moment arm of the force will be longer in the case of the more distal fracture and therefore the moment acting at the fracture site on the implant will be larger. For the more distal fracture, the high stress region close to the fracture site is also significantly closer to the distal locking screw holes which are significant stress risers. |

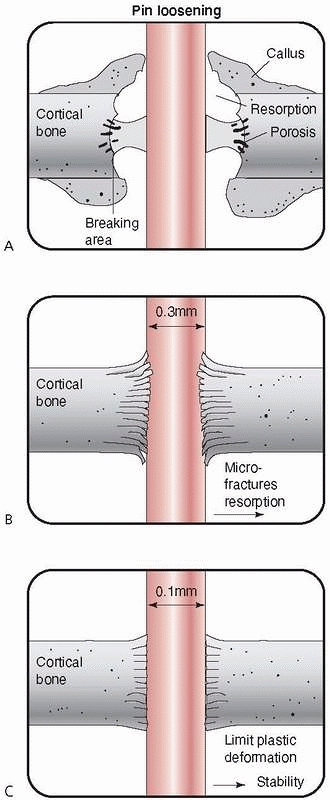

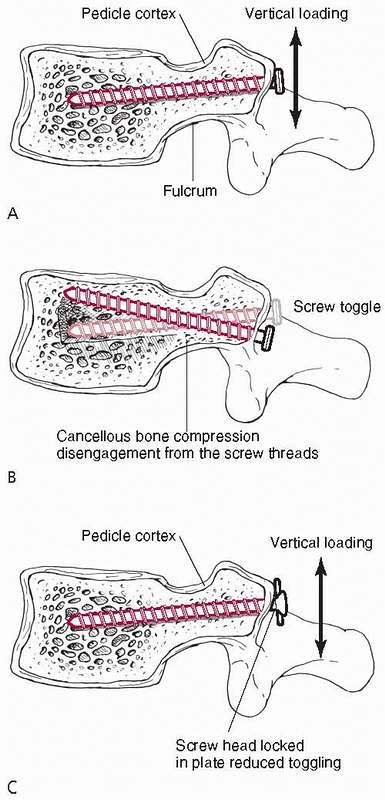

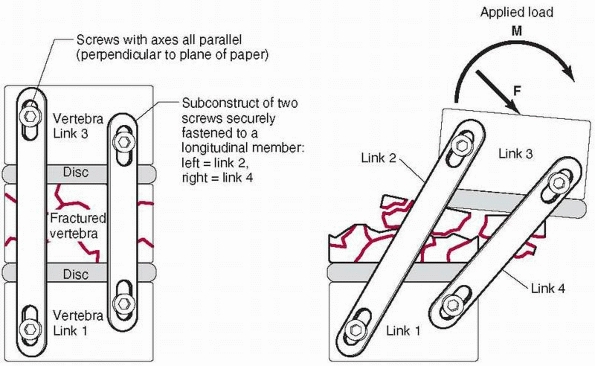

from several causes. The shape of the end of the pin itself, because it