PRINCIPLES OF INTERNAL AND EXTERNAL FIXATION

II – FRACTURES, DISLOCATIONS, NONUNIONS, AND MALUNIONS > General

> CHAPTER 11 – PRINCIPLES OF INTERNAL AND EXTERNAL FIXATION

combines five chapters from the second edition of Operative

Orthopaedics, written by Timothy J. Bray and David C. Templeman (screw

fixation), Fred Behrens (external fixation), David H. Gershuni (wire

and pin fixation), Thomas P. Rüedi (plate fixation), Harry B. Skinner

(materials), and myself. Much of the original material by these authors

has been retained in this chapter, and I wish to acknowledge and thank

them for their contributions.

employs an incredibly broad range of techniques, from fine

microvascular surgery to bone fixation implants, to large metallic and

polymeric composite implants for joint replacement, to sophisticated

methods of external fixation involving all regions of the skeleton.

Successful use of these implants and devices requires sophisticated

technical knowledge on the part of the surgeon, as well as respect for

the biology of the tissues being handled, for the best chance of a

successful result. The surgeon must be certain that the indications for

surgery are appropriate and that the patient is suitable for the

operation: Even the best-performed procedure will fail if the

indications are not correct and if the patient cannot benefit.

fixation implants are critical to achieving bone union in the

appropriate position and to avoiding implant failure. It is essential

that resident and neophyte surgeons master the general principles and

that mature surgeons constantly remind themselves of them, particularly

when they are employing fixation techniques that they do not perform

often.

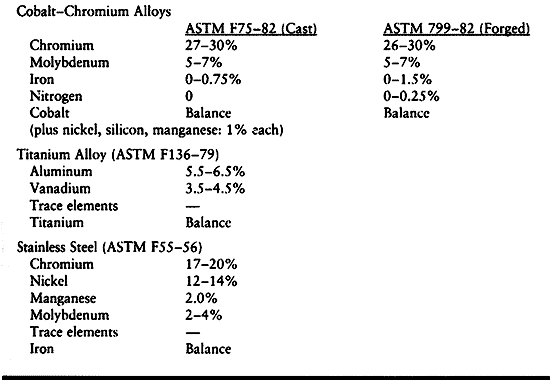

presence of a constituent element that has the ability to form an

adherent oxide coating that is stable and chemically inert. Materials

that do not form stable oxides or that permit the oxide to become

detached from the underlying metal, such as common carbon steel, are

not biocompatible and continue to undergo degradation in the body. The

common metallic alloys [e.g., cobalt chromium (ASTM F75-82, ASTM

799-82), titanium alloy (ASTM F136-79), and stainless steel (ASTM F55,

F56)] have at least one element that forms an adherent oxide coating.

The composition of these alloys is shown in Table 11.1. Detailed specifications of the composition are given in the American Society for Testing and Materials (ASTM) standards.

|

|

Table 11.1. Nominal Compositions of Implant Alloys

|

use of the material. For example, if ductility is not a requirement,

carbon is used to strengthen cobalt-chromium alloy (F75-82), although

carbon reduces the alloy’s ductility. Other phases present in each

alloy tend to stabilize the crystal structure. Forged cobalt-chromium

alloy is strengthened by nitrogen as a minor impurity. Certain elements

are deleterious to the properties, such as oxygen in a titanium alloy,

which tends to make it brittle. Similarly, carbon in stainless steel

decreases ductility unless it is allowed to precipitate in the grain

boundaries as chromium carbide, where it decreases resistance to

corrosion.

elements together to produce a liquid solution that subsequently

becomes a solid solution of each element in the matrix after cooling.

This material is shipped as a bar, rod, or plate for further processing

by the implant manufacturer. Titanium alloy can be shaped by machining

from bar stock or sheet stock; stainless steel implants can be produced

the same way. After initial forming of the more ductile version of the

cobalt-chromium alloys, forging significantly strengthens the alloy and

brings it to its final shape by applying mechanical work. The casting

process can be used for titanium alloy or cobalt-chromium alloy to

produce intricate shapes. A wax mold of the prosthesis is coated with

ceramic and fired. The wax melts out of the ceramic mold (i.e., lost

wax process); after cooling, liquid metal is poured into the ceramic

shape and allowed to solidify. Final shaping is done by machining and

grinding. Machining and forging done under appropriate conditions do

not diminish the mechanical properties of the alloy. However,

investment casting typically weakens the material by causing an

increase in the grain size. This mostly affects the fatigue life,

because for most materials the fatigue strength is inversely

proportional to grain size.

deformation and plastic or permanent deformation. Deformation at

strains lower than this level obey Hook’s law, which states that the

elastic modulus (Young’s modulus) is the proportionality constant in

the linear portion of the stress-strain curve below the yield point.

Fatigue strength refers to the ability of a material to resist

repetitive loading. Typical yield and fatigue strengths and elastic

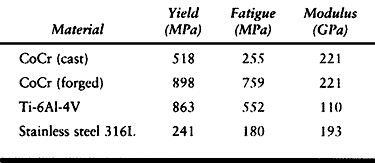

moduli are presented in Table 11.2.

|

|

Table 11.2. Typical Yield and Fatigue Strengths of Metal Alloys Used in Orthopaedic Surgery

|

material generated by the attraction of atoms within the material, and

it has essentially no variation with thermal or mechanical history.

Fatigue strength, however, can be significantly improved or diminished

by heat treatment. Cast cobalt-chromium alloy has a fatigue strength of

about 255 megapascals (MPa), which is only about twice that of the cast

stainless steel used in total hip prostheses in the early 1970s that

failed in fatigue. Titanium alloy, although quite strong in fatigue

strength in the “as received” or forged condition, can undergo

significant deterioration of its fatigue properties as a result of

applying a porous coating. Failure is caused by the creation of stress

concentration sites by the porous coating, and the grain growth caused

by the heat treatment used to apply the porous coating. Much of the

deterioration in properties of titanium alloy can be alleviated by the

use of a diffusion bonding process that lowers the temperature of

sintering. The notch sensitivity problem is managed by design

modifications that remove the porous material from areas subjected to

tensile loading. These concerns regarding the effect of porous coating

do not apply to implants for internal fixation.

the Rockwell test or the Vickers test, in which the material is

indented by a very hard object. The resistance to this plastic

deformation indicates the tensile strength of the material and its wear

properties. These tests are suitable for metallic alloys.

used material for bone fixation implants. The 3.16L alloy is still used

most commonly; however, other stainless steel alloys are also in use

and provide useful characteristics such as increased strength in hip

fixation implants, which can be subjected to high bending loads and

fatigue stress because of delayed healing (Table 11.1).

A major concern about stainless steel implants has been their

stiffness, which is approximately seven times that of human bone.

Uhthoff and Dubus (103) and others (16,27,63)

have demonstrated in animal experiments that when rigid internal

fixation is applied with stainless steel implants, prolonged exposure

of the bone can lead to porosis and weakening of the bone due to stress

protection. This is also seen in total joint arthroplasty, particularly

about the proximal portions of the stem in the femoral components of

total hip arthroplasty. Perren et al. (81,82)

have shown that the porosity and weakening observed is in part due to

the revascularization response resulting from the surgical procedure

itself; in spite of this, however, stress protection remains a

significant problem, particularly where the size and stiffness of the

implant is significant compared to that

of the bone. Chapman et al. (27),

in a review of 174 forearm fractures, found no refractures of the

radius or ulna after removal of AO 3.5 mm dynamic compression (DC)

plates, whereas in all three patients in whom the larger narrow DC

plates and 4.5 mm screws were used, refractures occurred either through

the screw holes or the fracture site.

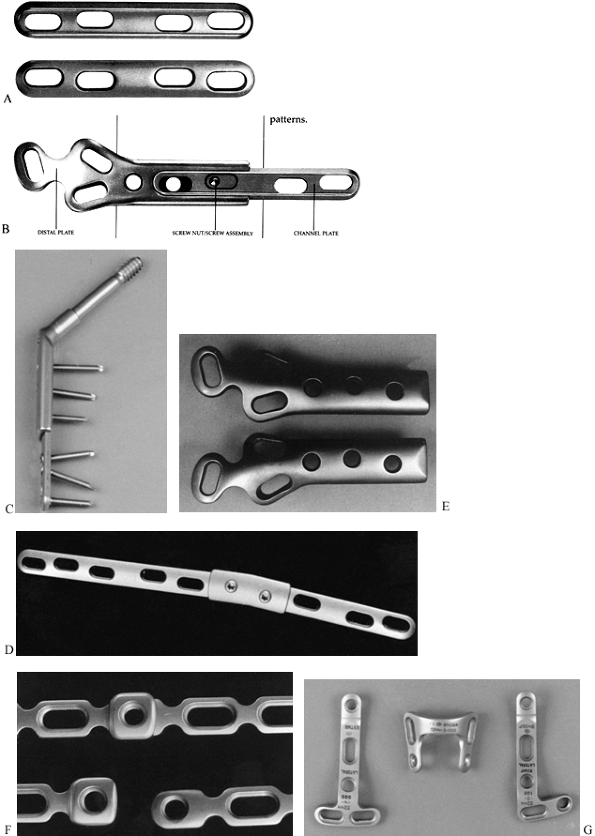

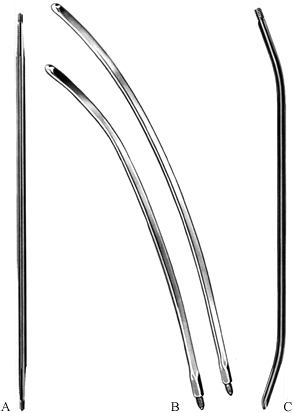

for plates and nails that is closer to bone in its mechanical

characteristics, yet would be stiff enough to permit fracture healing

and strong enough to avoid fatigue failure prior to fracture union.

Titanium and its alloys, widely used in military aircraft and

submarines, have proven, in part, to meet this need. Most manufacturers

have used a titanium alloy containing 6% aluminum and 4% vanadium (6-4

titanium). The mechanical characteristics of commercially pure (CP)

titanium were not suitable for internal fixation implants until

recently; however, the AO group has used plates and screws of CP

titanium, which have proven to be clinically useful. By utilizing

particular forging and other techniques, they have been able to render

the CP titanium sufficiently strong. Other alloys of titanium,

particularly beta alloys, offer even better mechanical properties for

internal fixation implants than the 6-4 titanium, and some of these are

listed in Table 11.1. Overall, titanium alloys

are approximately twice as flexible as stainless steel and at least

one-third stronger. A primary disadvantage of titanium is that it is

difficult to manufacture, which increases costs. Also, it is more

brittle than stainless steel: Cracks occurring from notches in the

metal tend to propagate much more easily than in stainless steel, which

influences implant design and how the surgeon uses the implants.

Titanium alloys become particularly useful in smaller implants, such as

nonreamed intramedullary nails, and in smaller plates, which employ

smaller-diameter screws, where the superior strength of the titanium

results in much less screw and nail breakage compared with stainless

steel. In spite of the increased cost, most major implant manufacturers

today offer bone fixation implants composed of titanium. Some entire

implant systems, both plates and intermedullary nails, are offered in

titanium.

than stainless steel, which has a tendency to experience crevice

corrosion at the contact point between screw heads and plates. Plate

failure can take place through these corrosion pits. Titanium

aggressively forms an oxide, which provides superior passivation of the

implants. I have removed numerous titanium plates and screws and have

never seen any visible evidence of crevice corrosion.

metallic ions into the local soft tissues and general circulation.

Although concerns have been raised about the potential toxic or

carcinogenic effects of these minute amounts of ions, and sarcomas have

been described in association with implants, no evidence has been

presented that implants are a significant health risk to patients. On

the other hand, current implant materials have been used for

approximately 60 years. Whether exposure to these implants for up to 80

or 90 years in our long-lived population will produce diseases is not

yet known. When placing these implants in children and young adults, a

discussion with patients and their parents regarding this issue is

appropriate. If concerns are expressed after implantation, and removal

of the implant will not incur unacceptable risks, then removal is

usually advised.

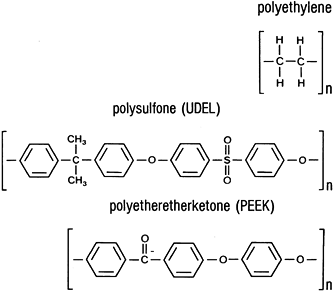

a routine basis. These are ultrahigh-molecular-weight polyethylene

(UHMWPE), polypropylene, polytetrafluoroethylene (PTFE, Teflon), and

polymethylmethacrylate. Other polymers show promise as matrix materials

for composite biomaterials, including polysulfone (UDEL),

polyethersulfone, and polyetheretherketone (PEEK). Their chemical

structures are shown in Fig. 11.1.

|

|

Figure 11.1. Chemical structures of implant polymers.

|

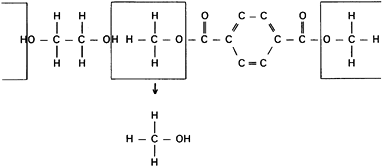

produce addition or condensation reactions. Condensation reactions

produce polymers by a combination of an organic acid and an organic

base to produce water or an alternative third compound (Fig. 11.2).

Reactive moieties on both ends of each type of molecule permit the

reaction to grow long chains. Additional polymerization produces the

polymer chains by adding one more link to a chain that was begun by an

initiator molecule reacting with a carbon double bond, such as found in

ethylene. Most implant

polymers are thermoplastic, because they can be melted and cooled until solid again with no composition change.

|

|

Figure 11.2. A condensation reaction showing the method used to produce polyester (Dacron).

|

possible, molding of granules of a polymer under heat and pressure,

called compression molding, is more common for production of

polyethylene components. Machining of implants from stock is another

technique that can be used. Both methods produce acceptable articular

surfaces for implants.

for metallic implants, but their interchangeability is not as great.

Polypropylene is used as a ligament augmentation device for knee

reconstructive surgery, UHMWPE is used as the bearing surface in total

joint arthroplasty, and Teflon is expanded to form a Gore-tex material

used in knee reconstructive surgery. Polymethylmethacrylate is

partially polymerized, provided as granules, and combined with monomer

and an initiator to form a final polymerized mass (e.g., Zimmer bone

cement). When copolymerized with polystyrene, polymethylmethacrylate is

used in a similar manner to form Simplex-P (Howmedica, Rutherford, NJ).

(copolymers of the two acids), and polydioxanone find their main uses

as resorbable suture materials under the brand names Dexon (Davis and

Geck; US Surgical, Norwalk, CT), Vicryl, and PDS (both manufactured by

Ethicon, Johnson and Johnson, Somerville, NJ). These materials are also

available as resorbable pins, primarily for fracture fixation in the

hand, foot, ankle, and skull (3). These

materials can be made relatively stiff and are slow to resorb.

Polylactic acid is now available as screws and pins because its slow

rate of resorption may reduce the level of inflammatory response.

Attempts at improving the stiffness of polylactic acid have included

mixture with hydroxyapatite fibers.

produced by high-temperature processing. Typically, ceramics have high

thermal and electrical resistance and high elastic modulus, low

ductility, and low tensile strength. Excellent biocompatibility results

from chemical inertness.

strengths, but brittle failure occurs after minor plastic deformation.

Although the failure strength is quite high in many cases, relatively

low failure stresses can occur occasionally.

but they have not proven practical because of the inability to conform

them to the bone, and because of their high failure rate caused by

their brittle nature. Because of the unique characteristics of

ceramics, they enjoy much more practical application in the bearing

surfaces of total joint replacement prostheses and in the coatings of

prosthetic implants where direct bone–implant ingrowth is desired.

which the mechanical performance of the composite is superior to that

of either component alone. In man-made composites, usually one

component is a fiber and the other is a matrix material. Bone itself

achieves most of its mechanical properties as a natural composite

material composed of calcium phosphate ceramics in a highly organized

collagen matrix.

made by an orthopaedic surgeon, was the plaster of Paris bandage. This

has been refined to fiberglass with a polymeric matrix in the current

synthetic casting materials. A composite for internal prosthetic

applications is based on the addition of chopped carbon fiber to

improve the mechanical properties of polyethylene components.

must be biocompatible. Three potential matrix materials that have

undergone at least preliminary biocompatibility studies are

thermoplastic and have similar structures (Fig. 11.1).

These are UDEL, polyethersulfone, and PEEK, discussed above. The fiber

materials strengthen and stiffen the matrix and can be used as chopped

fibers or as long fibers. The chopped fiber material usually produces a

composite that is isotropic, having stiffness and strength properties

that do not vary with direction. The long fibers can be woven, wound,

or formed in many geometric orientations to provide desirable

mechanical properties. Only carbon fiber is being studied for

orthopaedic applications.

which all the fibers run in one direction and are held together by a

thin coating of the polymer matrix material. It is produced by passing

the fibers through the polymer, allowing it to be coated, and

subsequently sticking the layers together and pressing them. This

laminate is combined with other laminates to form a bulk composite; the

properties of this composite vary depending on the orientation of each

layer of the laminate. The primary direction of the fibers is called

the zero direction, and other layers, or laminae, are oriented in

relation to this (e.g., 0°, 45°, -45°, 90°, +30°, and -30°) to vary the

properties of the polymer. A polymer that has equal numbers of layers

in the 0°, 45°, -45°, and 90° orientations is called a pseudoisotropic

polymer because the mechanical properties in any direction in the fiber

plane are the same. An alternative means of producing a composite

structure is to wind one or more continuous fibers in a particular

orientation to form the desired prosthetic shape.

strength and the modulus. The strength generally mirrors the modulus,

and both of these depend on the orientation of fibers. The elastic

modulus can be estimated for laminated structures from the two “rules

of mixtures.” The modulus parallel to the fibers (Eparallel) is proportional to the amount of fiber in a simple linear relationship:

are the volume fractions of the fiber and matrix, respectively. In the

range of typical polymer fiber used in a laminate of 0.4–0.7 volume

fraction fiber, the elastic modulus varies linearly in that range

parallel to the fibers. The modulus relationship perpendicular to the

fibers is more complicated and less applicable to all composites:

radiolucent, roentgenographic examination of fractures fixed with

external fixation devices made of these materials can be performed with

relative ease. Similarly, halo rings made of these materials are

compatible with magnetic resonance imaging, allowing studies of the

brain and cervical cord to be performed.

composites have been used experimentally for internal fixation. Their

potential advantages include radiolucency (making observation of

fracture healing easier), the ability to vary the modulus of the

material, and the potential for using an absorbable polymer. None of

these materials are currently in clinical use because of the inability

to modify the shapes of the implants intraoperatively to fit the bone;

because of liberation of carbon fibers into the adjacent tissues; and

because the difficulties of predicting the resorption of polymers in

larger load-bearing implants, as opposed to screws and pins, has thus

far precluded their use for these larger implants. No doubt, implants

in this category will be available in the future, perhaps even

containing bone inductive proteins.

were used for fracture fixation. Later, silver wire was introduced by

Lister to treat a patellar fracture. Parham and Martin (77)

described steel bands used around the shaft of fractured long bones in

1913, and in 1922 Johnson developed stainless steel, which is the

material still used for most types of wire and pin fixation. This form

of fixation includes fine Kirschner wires, larger Steinmann pins, and

flexible wire used for provisional and definitive fracture

stabilization, osteotomy fixation, and skeletal traction.

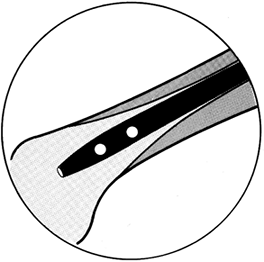

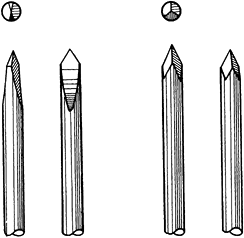

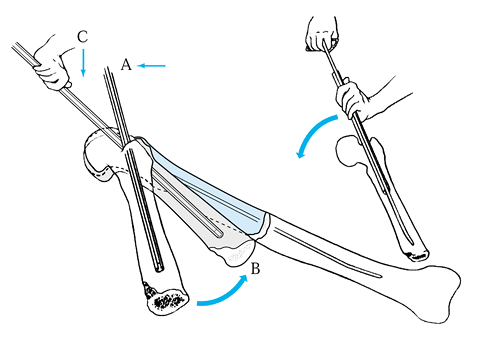

Germany, was the first to use thin wire pins for fracture management,

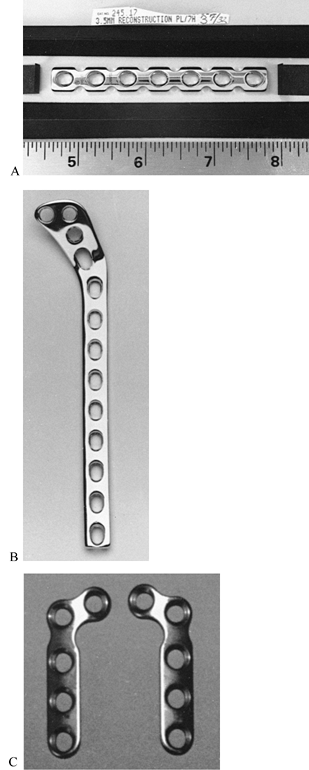

in 1909. Kirschner, or K- wires are manufactured in lengths from 7 to

31 cm and in diameters from 0.6 to 3.0 mm. They may be smooth or

threaded, but threaded wires have poorer bending strengths for a given

pin diameter and may be difficult to remove at a later date. The wire

may be pointed at one or both ends. In the latter case, the pin can be

inserted antegrade from the fracture site to exit from the distal

fragment and then retrograde back into the proximal fragment. K-wires

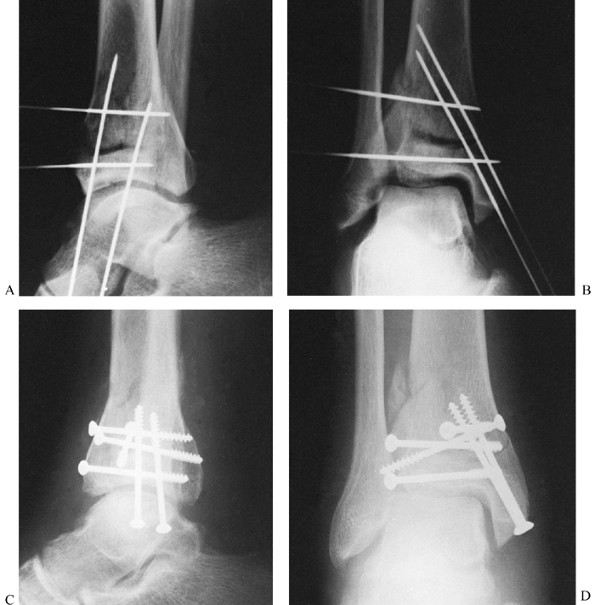

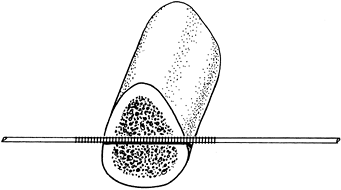

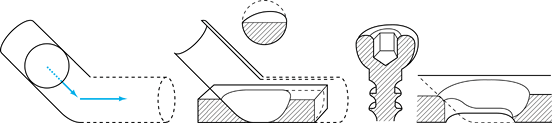

may be trocar or diamond pointed (Fig. 11.3). The trocar point

is somewhat easier to insert into dense cortical bone and there is less of a tendency to overheat.

|

|

Figure 11.3. Ends of Kirschner wires or Steinmann pins with trocar points on right and diamond points on left.

|

introduced with a power drill and a pin stabilization system, which may

be a telescopic guide attached to the end of the drill chuck, or an

external guide with a handle. The drill itself may have the capability

of rapid locking and release of the wire; advancement therefore can be

made from the barrel of the drill, which acts as the guide.

Small-diameter pins can be inserted through large bore needles. An

alternative is to introduce a gentle bow into the wire while drilling.

This prevents oscillation of the wire. Two disadvantages of this

technique are that the direction of the wire may be more difficult to

control and the wire will overheat more rapidly. When K-wires are used,

wire cutters and instruments for wire bending are required. The wire

benders may be simple metal tubes into which part of the wire is

inserted before being manipulated, or special pliers can be used (Fig. 11.4).

|

|

Figure 11.4. Instruments for wire bending. A: A metal tube with a flanged end. B: Special pliers.

|

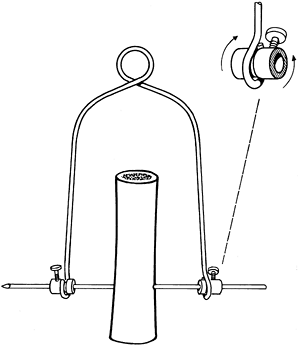

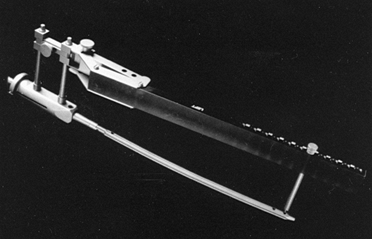

flexible, but the wire may be stiffened by applying tension with a

traction bow. The construct is thus made strong enough to apply a load

of approximately 20 kg, providing the bone is able to sustain this

weight (Fig. 11.5).

|

|

Figure 11.5. Kirschner wire tensioner and traction bow.

|

skeletal traction, particularly in children, in whom smaller traction

loads are required and the cosmetic advantages of a smaller skin entry

point pertain. K-wires can be used in any of the common sites for

skeletal traction in the treatment of extremity fractures such as the

upper end of the tibia, the lower end of the femur, the olecranon, and

the digits. In children, passage of traction pins across the upper

tibia risks damage to the physis, resulting in its partial closure and

a subsequent growth deformity. If the proximal tibia must be used, the

wire must be inserted posterior and distal to the physeal line.

unit area directed against the bone by the K-wire is greater than that

exerted by a larger-diameter pin. Osteopenic bone is therefore a

relative contraindication to use of a K-wire for traction. See Chapter 10 for additional details.

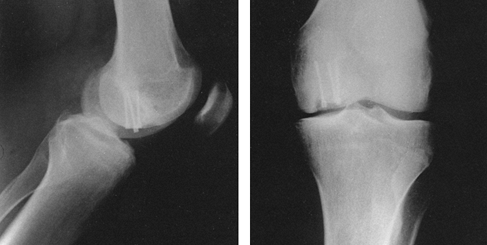

fractures, especially in the presence of comminution, in which the

definitive fixation of two fragments may impede the subsequent

reduction of the rest of the fracture, is that the fracture be

initially provisionally fixed. K-wires are particularly

useful,

and many of them may be used in combination, with little damage to the

bone or its vascularity. They may be used alone or in combination with

bone-holding forceps or cerclage wires. A complicated fracture can be

fully and accurately reduced and temporarily fixed with K-wires.

Radiographs may then be taken on the operating room table to

demonstrate the anticipated result or to demonstrate any defects in the

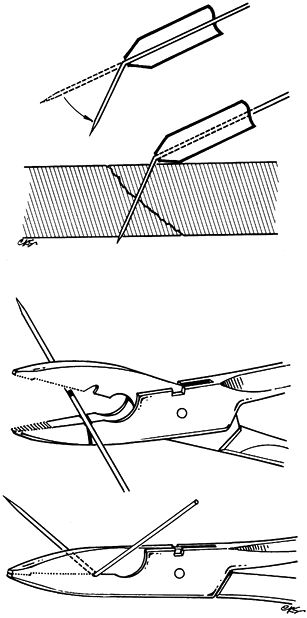

reduction and facilitate their correction (Fig. 11.6).

|

|

Figure 11.6. Tibial plafond fracture. A: Lateral radiograph shows provisional Kirschner wire fixation. B: AP radiograph shows provisional Kirschner wire fixation. C: Lateral radiograph after definitive screw fixation. D: AP radiograph shows definitive screw fixation.

|

provisional K-wire fixation to prevent the wires from interfering with

the later exchange to the definitive fixation with, for example, plates

and screws. Where K-wires are to be replaced by lag screws, introduce

the wires in the same direction that will be used later for the screw

fixation. Nonparallel K-wires will interfere with production of

satisfactory compression by lag screws across the fracture site (Fig. 11.6).

If crossed wires must be placed, remove them after the screw is in

place and before final compression. A simple trick to facilitate plate

application in the presence of multiple K-wires is, first, to place the

plate on the bone and mark the location of the holes on the bone with a

marking pen. Then, insert all the K-wires through the location of the

holes.

subsequent loading on a fractured bone is anticipated to be small

because the fracture is close to a joint or if the overall length of

the bone is not great. Thus, intra- and extraarticular fractures of the

phalanges, metacarpals, and metatarsals, and other bones of the carpus,

tarsus, and distal radius, may be stabilized with crossed Kirschner

wires.

-

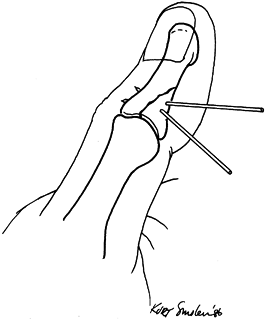

Insert the first K-wire at right angles to the fracture plane.

-

Compress the fracture fragments and place a second K-wire obliquely to lock and maintain the compression (Fig. 11.7).

In the fixation of transverse phalangeal fractures, it has been found

that four crossed wires provide the strongest fixation; and in oblique

phalangeal fractures, three wires at right angles to the fracture

provide the best stabilization (106).

Stabilization with K-wires in these cases must almost always be

supplemented and protected by plaster-cast fixation, but early motion

is important. Figure 11.7.

Figure 11.7.

Kirschner wire fixation of an intraarticular phalangeal fracture. One

wire is inserted at right angles to the fracture line, and the second

wire locks the reduction by its oblique insertion.

supracondylar fractures of the humerus in children: After closed or

open reduction, two K-wires inserted from the lateral side can maintain

good reduction when combined with external cast immobilization (see Chapter 164).

proximal end of the wire is left straight, there is a significant

likelihood of migration of the wire into or from the bone. Therefore,

the exposed end of the wire should always be bent with an appropriate

instrument if it will be left buried. If only a very small segment of

the wire is left exposed above the surface of the bone, it may be very

difficult to find later when metal removal is required. Another

alternative is to leave the end of the wire longer and just under the

skin to facilitate removal. Pressure on the skin from within (and

possibly from without due to dressings or plaster casts) may produce

skin necrosis and infection around the wire tip. It is therefore

recommended that either the wires be left buried with a bent end to

facilitate removal, or the tip of the wire be left protruding by a

centimeter or so from the skin. Prevent tension on the skin around the

wire and protect it from unwanted blows. Either cap the wire with a

commercially available wire cap or bend the end of the wire over. The

former is preferable as it prevents catching the end of the wire on

clothing. Reaction of the skin around the thin wire is minimal and

infection unusual as long as it is stable in the bone. Subsequent

removal of the pin is almost always easy and relatively pain free. In

situations where K-wires are used in a tension band construct and

functional postoperative therapy will be instituted, bend the ends of

the wires into a U shape and impact them into the bone.

Switzerland, introduced pins that were thicker than those of Kirschner

but otherwise very similar.

lengths of 150 to 300 mm. The pointed end is usually of the trocar or

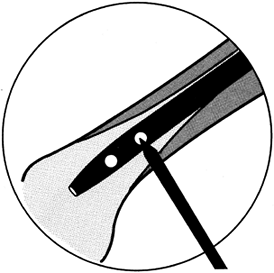

diamond-pointed design (Fig. 11.3), but cove points are also available (Fig. 11.8). The

cove point has a positive rake angle, which cuts bone rather than

scraping it as occurs with the trocar and diamond tips. Flutes

facilitate removal of chips from the hole made in the bone. Heat

generation when using the cove point is probably less than with the

trocar or diamond-tip Steinmann pin. In general, however, predrilling

with the appropriate drill bit is recommended before pin placement into

cortical bone. Predrilling is usually not necessary in cancellous bone.

|

|

Figure 11.8. The cove point of a Steinmann pin.

|

of the pin facilitates fixation within the bone so that infection,

which is facilitated by metal–bone motion, is prevented. Steinmann pins

that are threaded only in the central region are easier to introduce

and are as effective as fully threaded pins (Fig. 11.9). The thread diameter is 0.5 mm larger than the pin, so that the threaded segment is no weaker than the remainder of the pin.

|

|

Figure 11.9. Centrally threaded Steinmann pin with the threads spanning the cortices of the bone.

|

femur, the tibia (proximal or distal end), or the os calcis. Traction

is best applied with the use of a Böhler stirrup or bow, which fits

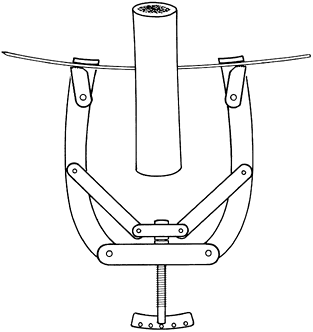

over the ends of the pin. The design of the clamps holding the pin is

such that movement of the stirrup does not rotate the Steinmann pin and

cause it to loosen, because the bearings on the stirrup clamps allow

free rotary movement on the pin (Fig. 11.10). See Chapter 10 for technical details.

|

|

Figure 11.10.

Böhler traction stirrup showing its fixation to the Steinmann pin while allowing rotary movements of the stirrup around the pin. |

pins into each end of a long bone fracture and then, after reduction,

incorporation of the pins into a cast (i.e., “pins-and-plaster”

technique) was used for many years. The stability of this construct is

not very satisfactory, however. There is always a tendency for the

plaster cast to loosen and, by its weight transmitted to the pins,

provoke pin loosening and pin tract reactions (see Chapter 10).

The use of pins-and-plaster techniques has largely been replaced by the

more efficient and advantageous external skeletal fixators, which are

discussed later in this chapter and in the various sections on

fractures.

and T-handle or hand drill into soft bone, but this technique tends to

lead to inaccurate pin placement. Particularly in hard cortical bone,

such as the upper end of the tibia in young people, free-hand

introduction of a Steinmann pin is very difficult and inaccurate; in

this situation, always predrill the pin tract with a drill bit having a

cutting tip that does not generate heat. The use of a power drill to

insert the Steinmann pin directly into dense bone may generate

sufficient heat to cause bone necrosis; infection frequently ensues

with loss of fixation and development of a ring sequestrum and

osteomyelitis.

are used in the external fixation of bones, are discussed later in this chapter.

-

Make an initial skin stab incision with its long axis in the line of subsequent traction pull.

-

Use a soft-tissue guide over the appropriate drill bit and drill a pin tract at right angles to the subsequent traction pull.

-

Then introduce the Steinmann pin by hand

into the bone with a Jacobs chuck and T-handle, making the skin

incision at the exit site of the pin tip. Little heat is generated with

a sharp drill, so bone necrosis does not occur; infection, loosening,

and sequestrum formation are much less likely, and greater accuracy of

pin placement is achieved. -

Apply a Böhler traction bow or stirrup to the pin and apply traction.

-

Release any skin compression developed on

applying the traction by incising the skin next to the pin; this is

necessary to prevent skin necrosis and subsequent infection. Keeping a

snug fit of the skin on the pin in the absence of tension on the skin

minimizes motion of the skin on the pin and helps to prevent infection,

so close any excessive incision. Keep the pin sites dressed in a

sterile fashion and cap the pointed tip of the Steinmann pin to prevent

injuries.

understanding of active and passive muscle forces allows the use of a

minimal amount of fixation material to obtain excellent fracture

stability and immediate functional movements of the contiguous joints.

The principle of the tension band wire is that tensile fracture

distracting forces, which the wire can easily absorb, are converted

into stabilizing compression forces passing through the bone. It is

essential that the cortex distant from the tension band side be strong

enough to bear the applied compressive load. Loss of bone stock or poor

bone quality will allow development of bending stresses, leading to

wire fatigue and failure of the fixation. Tightening of the tension

band wire produces static compression, particularly through the cortex

under the wire. On active joint flexion, dynamic compression results

across the whole of the fracture surface.

considerable ductility, combined with a high yield point and ultimate

tensile strength. The wire is usually available in diameters from 0.4

to 1.5 mm made from type 316 stainless steel or Vitallium. The modulus

of elasticity of Vitallium is higher than that of steel and for the

same strain should support higher loads than stainless steel of equal

diameter. Wire is weakened by cold working (e.g., kinking, bending,

twisting), so care must be taken to avoid damage during implantation.

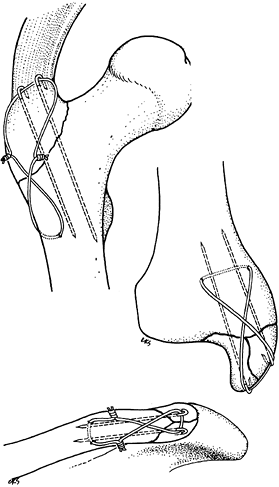

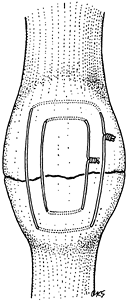

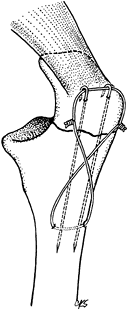

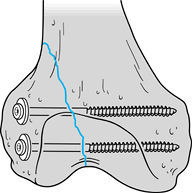

wire alone, as in a transverse fracture of the patella in which an

irregular fracture line allows perfect reduction by interdigitation of

the fracture surfaces (Fig. 11.11). In most

situations, however, axial rotational stability cannot be obtained

without the addition of two parallel, longitudinally placed K-wires (Fig. 11.12).

In comminuted fractures, the K-wires also assist in providing some

interfragmentary stability, which is completed by the tension band

wire. The K-wires must be inserted in a parallel fashion. Crossed wires

provide much less rotational stability and interfere with

interfragmental compression. The K-wires also provide anchorage points

around which the tension band wire can be placed.

|

|

Figure 11.11. Transverse patellar fracture stabilized by two tension band wires.

|

|

|

Figure 11.12. Transverse patellar fracture stabilized with two parallel, longitudinally placed K-wires and tension band wire.

|

|

|

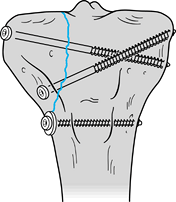

Figure 11.13. Transverse olecranon fracture stabilized with two parallel, longitudinally placed K-wires and a figure-eight tension band wire.

|

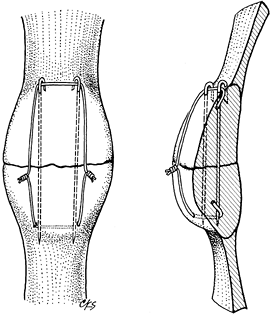

-

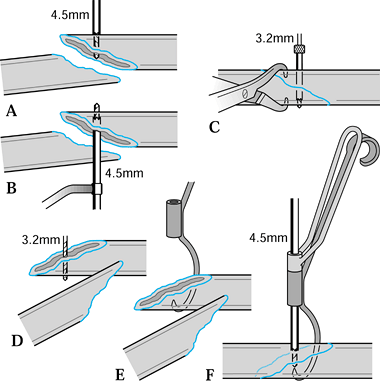

After exposure of the fracture, place a 2

mm drill hole 2–3 cm distal to the fracture in a transverse fashion,

passing just ventral to the dorsal cortex (Fig. 11.13). Then pass a 1.0 mm (18-gauge) or a 1.2 mm (16-gauge)

P.319

diameter wire through the hole and displace the wire distally out of the proximal fracture field. -

To control fragment rotation, insert two

1.6 mm diameter K-wires parallel from the tip of the olecranon into the

distal fragment (Fig. 11.13). This can be

achieved using a 2 mm triple guide, or the wires can be inserted

retrograde from the fracture site to exit the tip of the olecranon. -

After fracture reduction, advance the 2

K-wires 3 or 4 cm into the distal fragment. Alternatively, the wires

can be inserted in an antegrade manner from the tip of the olecranon

before fracture reduction, allowing their accurate placement within the

medullary canal to be confirmed before reduction and driving of the

wires across the fracture site. With more experience, after anatomic

reduction of the fracture, the K-wires can be inserted from the tip of

the olecranon across the fracture site and into the distal fragment.

More secure fixation is obtained by drilling the wires through the

anterior cortex rather than placing them in the medullary canal. -

Place the ductile wire around the

protruding proximal tips of the K-wires in a figure-eight fashion. Be

certain that they are against bone. Throw a simple loop in the midpoint

of one limb of the figure eight, and complete the opposite limb by

twisting the two ends of the wire (Fig. 11.13).

Twisting the loop and two ends of the wire alternately allows

well-controlled and equal tension in the whole figure-eight wire.

Achieve wire tightening with bullet-nosed pliers, being careful that

the wire ends are arranged in a helical fashion one around the other

and that the pliers do not score the tensed wire. Shorten the twisted

wire ends and the twisted loop to about three helical twists, and bend

the wire ends away from the subcutaneous region to lie alongside the

bone. Bend the proximal protruding K-wires twice, shorten them

appropriately, and then impact them, like a staple, into the bony tip

of the olecranon (Fig. 11.13); this prevents

migration of the pins. Even with some comminution of the olecranon, the

tension band wire technique can still be used after reduction and

fixation of the minor fracture fragments with lag screws; thus,

excision of the olecranon can usually be avoided. -

Commence immediate postoperative active

flexion exercises for the elbow; extension exercises should proceed

with more care because the bone–fixation complex is less stable in

extension. If the proximal ends of the K-wires are not sufficiently

impacted into bone, they can back out and protrude under and even

through the skin (68). Another occasional

complication is for the tension band wire to cut out of the distal

fragment if it has not been inserted deeply enough below the dorsal

cortical surface. After fracture union, the tension band wires tend to

be uncomfortable. Removal is often necessary. The tension band wiring

technique can similarly be employed for transverse and comminuted

patellar fractures, fractures of the femoral greater trochanter,

fractures of the malleoli (particularly where small or osteoporotic

fragments are involved), and fractures of the distal end of the

clavicle (Fig. 11.12 and Fig. 11.14).![]() Figure 11.14.

Figure 11.14.

Tension band wiring techniques employed to stabilize greater

trochanteric, comminuted medial malleolar, and distal clavicular

fractures.

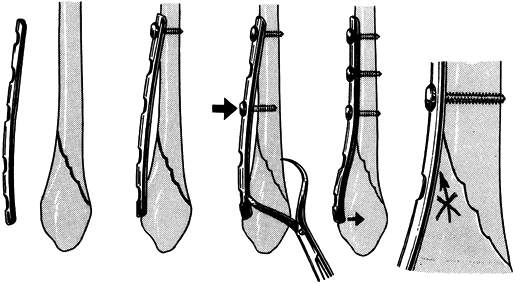

provisional fixation of long-bone fractures or for definitive fixation,

usually in combination with other fixation devices.

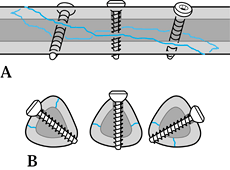

that described for use in tension band wiring. Wire diameters of 0.8 to

1.25 mm are commonly used, and the strength varies directly with the

square of the diameter. Two wires may be twisted to form a double

strand, which may have greater flexibility than a single wire and is

less likely to slip on the bone. Some cerclage wires are manufactured

with a loop in one end, so that after passage around the bone the other

end can be threaded through the loop and kinked backward to quickly

achieve temporary fixation (Fig. 11.15).

Regular wire can be tightened around the bone by twisting the two ends

one around the other in a helical fashion with the aid of bullet-nosed

pliers or one of the many available wire tighteners, while maintaining

adequate tension on the wire (Fig. 11.15). A

minimum of two full twists is necessary for maximum strength with 1.0

or 1.2 mm diameter wire, and the pitch of the twists should be as high

as possible (50).

|

|

Figure 11.15. Methods of joining ends of wire. A: One end of the wire is passed through a loop in the other end and kinked backward for temporary fixation. B: Helical twisting at a high pitch at the ends of the wire for temporary or definitive fixation. C: Technique like (A) but with one end of the wire passed under itself and against the underlying bone.

|

than the yield strength of the wire is satisfactory. For definitive

cerclage wiring, it has been suggested that tying a formal square knot

between the wire ends produces a fixation least likely to disengage (50).

After the first throw of the knot and subsequent tightening, however,

it is very difficult to maintain wire tension during the second throw

of the knot (47,86).

Although it is unlikely to completely unfold, with time the knot will

commonly relax and precipitate failure of fixation. Knots therefore are

suitable only for wire securing soft tissues. Helical twisting of the

wire ends is easily applied, maintains the initial fixation tension,

and will untwist only at tension loads beyond an acceptable limit.

Anchoring the twisted wire tips by folding them down into a predrilled

hole has been shown to produce the least slippage compared with other

methods (48). The AO loop with bending of the

free end under the wire also produces a satisfactory fixation strength,

but the passing of the free end of the wire between bone and the

tightly opposed cerclage can be very difficult (Fig. 11.15) (50,111).

use by yielding, elongating, or fatiguing due to repetitive loading.

This is especially true if the wire has in any way been scored before

or during application (29).

condemned as interfering with the periosteal circulation and thus

producing bone necrosis. However, it has clearly been shown that the

bone cortex receives most of its vascular supply in a centrifugal

fashion from the medullary cavity, and even complete loss of periosteal

blood supply may

not

lead to cortical necrosis. The periosteal vessels also tend to pass

vertically into the cortex and not run along the cortical surface.

Therefore, thin cerclage wires placed circumferentially at intervals

are unlikely to severely damage periosteal blood supply in mature or

immature bone (46,85,112).

This contrasts with previously used wide Parham bands, which did

eliminate periosteal blood supply from relatively wide segments of

underlying bone (77,85).

Recent modifications of Parham bands, as described by Partridge, are

made of nylon and have elevations on the underside of the band that

prevent wide contact and constriction on the bone by the band (78).

This modified form of cerclage fixation may be useful in situations in

which severely osteoporotic bone prevents other forms of stable

internal fixation.

control butterfly fragments in femoral shaft fractures, in which

erosion of the bands into the cortical bone has sometimes been found (54).

circumferentially around the bone in the treatment of patellar

fractures is now considered obsolete. This technique is not efficient

and permits fracture fragment separation and mobility (108). Tension band wiring techniques described in this chapter are much more applicable to the problem.

butterfly fragment is diametrically opposite the line of approach to

the bone, the judicious application of a temporary cerclage wire may

hold the butterfly fragment reduced so that lag screws may be inserted

into it (Fig. 11.16). After stable screw fixation, remove the cerclage wire.

|

|

Figure 11.16. Temporary cerclage wiring to facilitate lag screw fixation.

|

prophylactically around the femur to prevent splitting during press-fit

insertion of an uncemented femoral prosthesis.

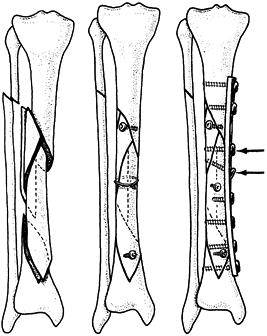

incisions to treat oblique or spiral diaphyseal fractures appears at

first to be attractive (24,86).

Even if stable fixation is initially obtained, however, the likelihood

of the development of fracture angulation and loss of stability is

significant because of the inevitable loading of the bone.

Supplementation with some form of external casting is required, and

this obviates early functional treatment of the limb. Stable closed

intramedullary nailing of a diaphyseal fracture usually solves the

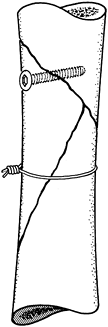

problem more efficiently than cerclage wiring alone. However, several

cerclage wires may be used in a supplementary fashion at 1 cm intervals

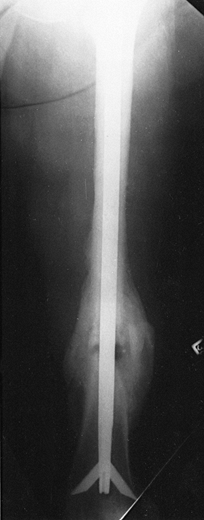

along the shaft with intramedullary nailing (Fig. 11.17) or Ender rodding and as an adjunct to the Zickel nail in subtrochanteric fractures (53,73,118).

|

|

Figure 11.17. A: AP radiograph of femoral fracture with one large, free fragment. B: AP radiograph of femoral fracture treated with intramedullary nailing and three cerclage wires.

|

-

Pass the wires at 90° to the long axis of

the bone so as not to slip longitudinally and loosen. All cerclage

wires around the bone should be placed under the same tension to

distribute the subsequent strain evenly between the wires; a wire

tightener whose tension can be calibrated is necessary. -

Use a wire passer to facilitate passage of the wire around the bone and minimize soft-tissue trauma.

-

Obtain anatomic reduction of the fracture

before wire tightening; otherwise, wire loosening in the postoperative

period is likely as settling of fracture fragments occurs. Cerclage

wiring techniques may also be used in the proximal femur where a

fracture has occurred during or after the insertion of a femoral

prosthesis. Cerclage wiring can be very effective in this situation if

care is taken to slightly notch the bone to prevent the wire from

sliding distally along the taper of the femur.

developed a cerclage system employing two different sizes of cable that

can be crimped to a grappling device. Similar devices are available

from most orthopaedic implant companies. The mechanical properties of

the multifilament cable are superior to monofilament wire in resistance

to fatigue, and the cable has a higher yielding and breaking strength.

The cable is also easy to work with because it does not have a tendency

to kink. The cable-grip system was originally developed to facilitate

reattachment of the greater trochanter in total

joint arthroplasty, but it has proven to have many applications in internal fixation (34).

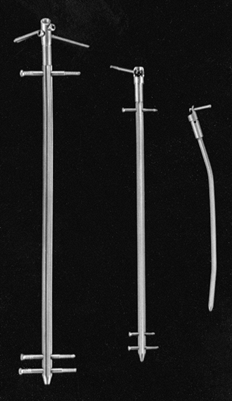

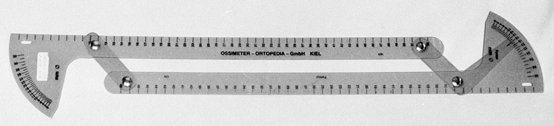

popularity, and designs of external fixators have changed continuously.

A variety of reliable pin fixators are now available with different

clinical and mechanical properties (13). Ring

fixators have become accepted tools for correcting limb-length

discrepancies and malalignments, compensating for bone loss, and

correcting soft-tissue contractures (72).

Additional indications for ring fixators include severely comminuted

peri- or intraarticular fractures, particularly in osteopenic patients.

Recent efforts to make external fixators safer and more effective have

made them invaluable tools in the care of injured and deformed

patients. The devices are as reliable as plaster casts and internal

fixation, yet more versatile, and they encompass a wider range of

indications (13,14,37).

External fixators are most useful when other methods of skeletal

fixation seem too risky or when temporary fixation is required until

tenuous soft-tissue conditions have resolved and definitive internal

fixation is safer.

for pin and ring fixators, this chapter focuses on pin fixators that

predominate in the treatment of acute, traumatic, and infective

conditions. See Chapter 32 for a thorough

discussion of ring fixators. Comminuted juxtaarticular fractures,

particularly in the proximal and distal tibia and distal femur, are now

frequently managed with hybrid external fixators, putting to best use

the advantages of a ring fixator adjacent to the joint and a unilateral

half-pin fixator on the diaphysis.

confusing, closer analysis shows that each device comes with a limited

number of similar components. These can be assembled into four frame

types with distinct clinical properties and mechanical features (9,13).

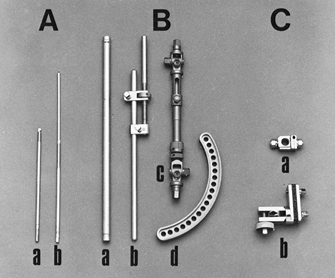

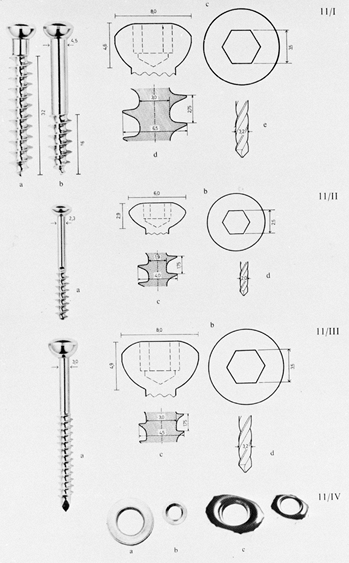

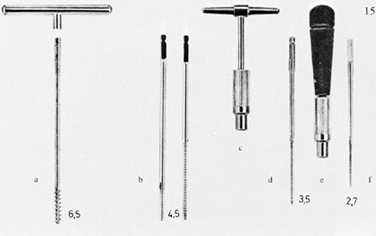

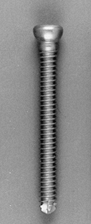

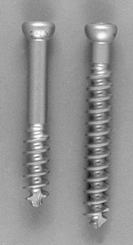

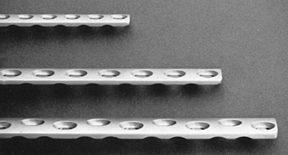

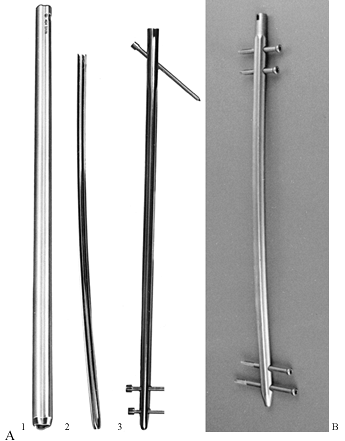

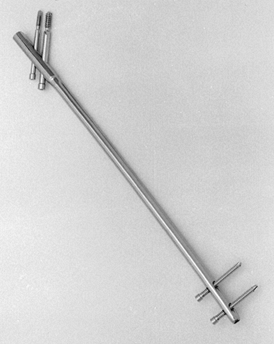

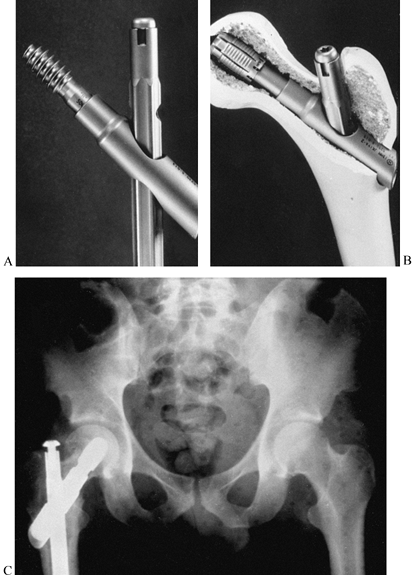

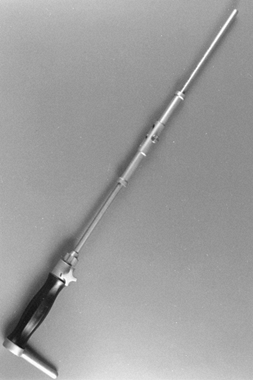

on one end and rounded or sharp tips. I prefer self-cutting and

self-tapping pins (Fig. 11.18) as they are

simple to use. Various diameters and lengths are available, from the

smallest for the digits up to the largest for the femur and pelvis.

|

|

Figure 11.18. A: Pins. a, Half-pins; b, centrally threaded transfixion pins. B: Connecting elements. a, Simple rod; b, rod with compression and distraction capabilities; c, rod with terminal universal articulations and capability for compression, distraction, and free axial sliding; d, circular connecting element. C: Articulations. a, Simple, adjustable clamp; b, universal clamp.

|

same or in different bony fragments. Complex rods have in addition a

built-in capability to compress or distract, provide axial loading

across the fracture at specific loads and excursions, and provide

articulations for angular adjustments.

pins, two rods, or a pin and a rod. Modular articulations hold two or

more pins in one clamp, which is connected by a universal joint to a

longitudinal rod.

quantitative torque-measuring capabilities, to tighten the

articulations; hand-held devices to insert and remove pins; drill bits;

drill guides; depth gauges; pin caps; removable compression devices;

and pin cutters.

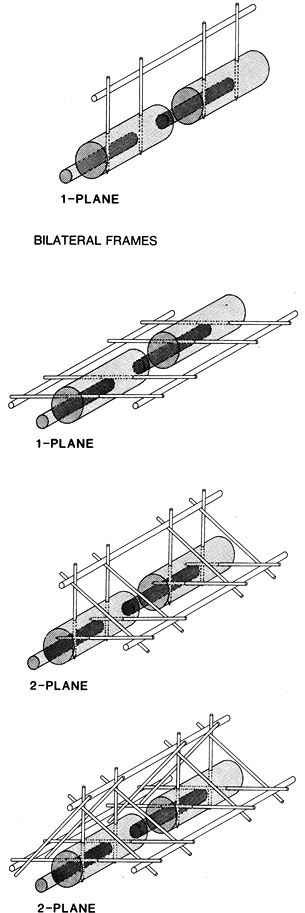

components of a device is called a fixator frame or fixation

configuration. In accordance with a frame’s space requirements, we

differentiate between unilateral and bilateral frames (11)

and multiplanar devices. Each of the former two frame types can be

applied in a one- or two-plane configuration. One-plane configurations

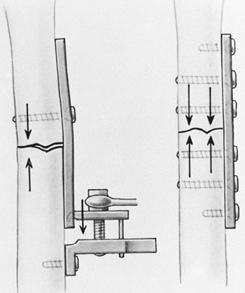

are less cumbersome, and two-plane configurations are more effective in

neutralizing bending and torsional moments (Fig. 11.19).

|

|

Figure 11.19.

The four basic configurations of external fixation frames. (From Behrens F, Searls K. External Fixation of the Tibia: Basic Concepts and Prospective Evaluation. J Bone Joint Surg Br 1985;68:246, with permission.) |

In the past, however, they were afflicted by a high rate of pin tract

infections, malunions, nonunions, and component failures (25,96,105).

Weight bearing was often possible only after advanced consolidation of

the fracture callus. Most of the mechanical disadvantages of these

configurations have been resolved through the introduction of stiffer

components or a combination of stiffer

components and mechanical optimization of frame designs (10,37,41).

Two-plane unilateral frames (e.g., Delta frame, tent frame, triangular

frame) can provide increased frame stiffness even with the use of

relatively weak components, but they are more cumbersome and may

interfere with wound access and secondary operative procedures (9,11).

frame, bilateral frame) were frequently used during the 1970s, when it

was felt that the transfixion pins and the bilateral longitudinal

support system would render them considerably stiffer than the

traditional unilateral designs (56,105). Subsequent mechanical studies showed that these frames are rather weak in resisting sagittal bending moments (12,19).

The insertion of multiple closely spaced transfixion pins caused

compartment syndromes, neurovascular injuries, and impairment of

musculotendinous units with resulting joint stiffness (11).

One-plane bilateral frames are therefore considered unsafe in most

locations and have been largely abandoned. The stiffest configurations,

two-frame bilateral frames, have been advocated for the management of

infected and unstable fractures, in particular pylon fractures of the

ankle, or to provide optimal conditions for bone healing. Although

mechanically better balanced than one-plane bilateral frames, they are

not commonly used today; new unilateral fixators work as well and are

not afflicted with all the disadvantages and complications caused by

transfixion pins and bilateral rods.

The frame must minimize obstruction to other operative procedures, be

adaptable to a wide variety of injury patterns, and be stiff enough to

maintain alignment under various loading conditions. Its use should

facilitate full weight bearing yet produce a low rate of serious

complications. These goals are best achieved by adhering to three basic

principles (9,11,14).

In decreasing order of importance, these principles demand that an

applied frame minimize the risk of injury to the vital limb anatomy,

provide ready access for wound debridement and secondary procedures,

and meet the mechanical demands of the patient and the injury.

which pins can be safely inserted is primarily determined by the

location of the main vessels, nerves, and musculotendinous units. Of

the two limb segments that make up the lower extremity, the distal

segment is much better suited for the application of an external

fixator, because the principal bone lies eccentrically and the pins can

be inserted through a subcutaneous bony corridor (14,42).

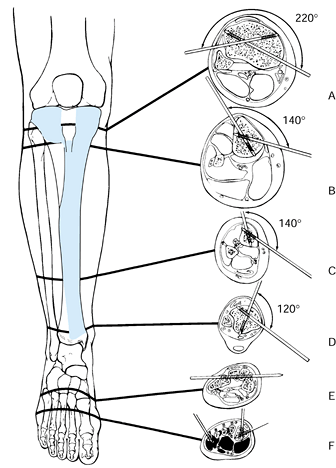

show that in the proximal third of the tibia, pin placement is safe

within an arc of 220°, which extends from the posteromedial border of

the tibial plateau to the proximal tibiofibular joint (42).

Excluded is a small rectangular area overlying the patellar tendon.

This safe anteromedial corridor decreases to 140° just below the tibial

tubercle and to 120° at the ankle joint. Therefore, half-pins are

safest distal to the tibial tubercle. Full transverse pins tie down the

muscles of the anterior compartment; in certain locations neurovascular

structures are threatened by injury

from a pin, so their use should be minimized and their insertion should be done judiciously.

|

|

Figure 11.20. The “safe corridor” for pin insertion in the lower leg. A: Proximal to the tibial tubercle, pins can be safely inserted within an arc of 220°. B: Just below the tibial tubercle, the safe arc decreases to 140°. C:

In the distal third of the leg, the safe arc remains 140°, but the anterior tibial vessels and deep peroneal nerves become vulnerable as they cross the lateral tibial cortex. D: Above the ankle joint, the safe arc is 120°. E,F: Pins in the tarsal or metatarsal bones may be used to splint the ankle joint if neurologic or soft-tissue injuries prevent the application of an external support. (From Behrens F, Searls K. External Fixation of the Tibia: Basic Concepts and Prospective Evaluation. J Bone Joint Surg Br 1985;68:246, with permission.) |

attention. Proximally, a pin can pierce the protective posterior muscle

layer and injure the posterior neurovascular structures. This is

prevented if the pin exit area is limited to the medial third of the

posterior tibial cortex. In the distal third, the anterior tibial

vessels are vulnerable along the lateral tibial cortex, which therefore

should be avoided. Whenever possible, pin placement should be limited

to areas where the tibia lies subcutaneously.

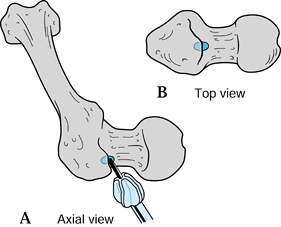

femur is circumferentially covered with soft tissues. There is no ideal

corridor available as all pins pierce the thigh musculature before they

are seated in the bone (3). Preferred pin

placement is from the lateral side, just anterior to the intermuscular

septum. Half-pins are essential because they transfix only the vastus

lateralis. Sometimes the pins can be inserted anterior to the lateral

intermuscular septum and posterior to the vastus lateralis, but they

still limit the excursion of the iliotibial band and thus restrict knee

motion while the fixator is in place (3,9).

Medial-pin exit sites that are between the midfemur and the distal

fifth are in a danger zone, because in this region the superficial

femoral vessels and the saphenous nerve are tightly held in the

adductor canal and are vulnerable to pin injury. If pins in these

locations are essential, place them using open technique and avoiding

the neurovascular bundles. These same considerations apply to the upper

extremity. Only the subcutaneous borders of the long bones are

reasonably safe, but even there tendons and cutaneous nerves are still

at risk of injury. In general, place upper-extremity fixation pins with

open technique.

of safe frame types to one- or two-plane unilateral configurations.

Within the safe soft-tissue corridor, the best pin location, frame

geometry, and frame placement are determined by the size and severity

of soft-tissue lesions, and by the comminution and stability of the

bone injury. Adapt each frame to the injury at hand to permit the best

possible wound access for initial care, repeated debridements, and

secondary soft-tissue procedures such as the transfer of local and

distant soft-tissue flaps and the placement of bone grafts. Within the

safe corridor, place pins and frames away from the injured area and the

principal access routes. If an injury involves mainly the medial side

of the leg, apply the frame anteriorly or anterolaterally; a lateral

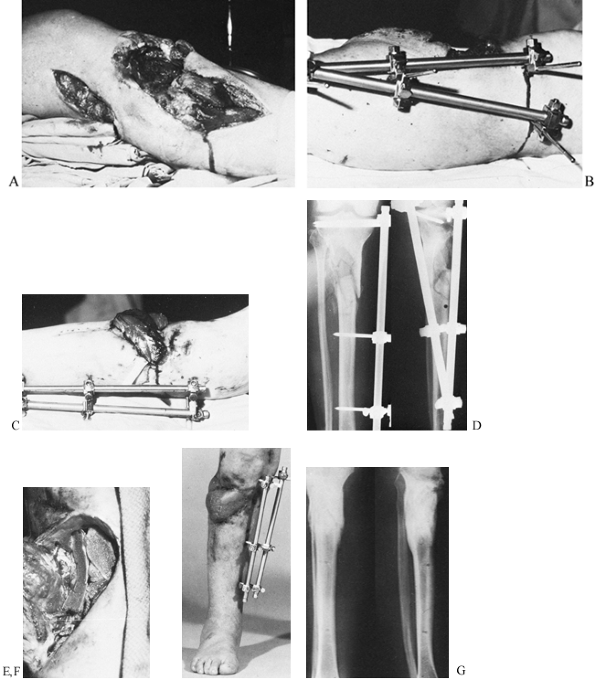

injury may call for a medial or anteromedial frame (Fig. 11.21).

|

|

Figure 11.21. A gunshot wound involving the lateral aspect of the proximal tibia with severe loss of soft tissue and bone. A: Initial appearance from the lateral side. B: Stabilization by an external fixator placed on the medial side. C:

The soft-tissue defect covered by a lateral gastrocnemius flap; there is no interference from the fixator frame. A split-skin graft was used to cover the muscle flap. D: Radiographs at this stage. E: Elevation of the healed gastrocnemius flap to allow the skeletal defect to be bone grafted. F: At 5 months, the fracture has healed, and the patient has borne full weight for 4 weeks. G: Radiographs 1 year after the injury. (From Behrens F, Searls K. External Fixation of the Tibia: Basic Concepts and Prospective Evaluation. J Bone Joint Surg Br 1985;68:246, with permission.) |

frame should control the prevailing forces and moments at the fracture

site. Information based on the size and weight of the principal lower

extremity segments and the distribution of the muscles surrounding the

femur and tibia indicate that, in the supine position, sagittal bending

moments are two to five times larger than the moments acting in the

frontal plane. After a patient is weight bearing, compressive loads and

torsional moments around the longitudinal axis gain in importance (11).

However, there is little change in the ratio of

anteroposterior-to-frontal bending moments. This suggests that

regardless of other mechanical properties, a fixator frame in the lower

extremity should be about two to five times stiffer in the sagittal

than in the frontal plane (12). For tibial

fixators, this stiffness ratio is most easily achieved if the principal

pin plane is oriented in an anteroposterior (AP) direction. Although

clinically appropriate, lateral femoral frames are not ideal

mechanically because they are relatively inefficient in resisting

fragment motion in the sagittal plane. To

counteract

this tendency, spread the pins in each principal bony fragment as far

apart as possible. Use stiff longitudinal rods and double-stack them if

necessary (3).

geometry are other factors that influence the application of a

mechanically effective frame. Assuming that stainless steel components

are used, the pins should have a diameter of at least 5 mm, and the

longitudinal rods should have a diameter of 8 mm or more. The

articulations must not slip within the range of clinically applied

torques. Experimental work has shown that the following methods

increase frame stiffness in one or more loading modes (10,12):

-

Increasing the pin spread within each main bony fragment (14)

-

Reducing the distance between the bone and the longitudinal rods (13)

-

Attaching a second longitudinal rod to the same pin plane (10)

-

Erecting a second half-frame at an angle to the first (i.e., creating a two-plane unilateral frame)

accommodate most tibial and femoral injury patterns without the need

for bilateral frames. Unilateral frames suffice for most

upper-extremity injuries.

Although much of this planning process occurs before the fixator is

applied, it must anticipate the most likely time course of healing and

the principal variations and potential complications that might be

encountered.

premorbid condition, socioeconomic circumstances, and the cause,

severity, and extent of the injuries. Determine whether external

fixation is the best method for treating the patient’s injuries, what

is the best device and in what configuration, whether the fixator will

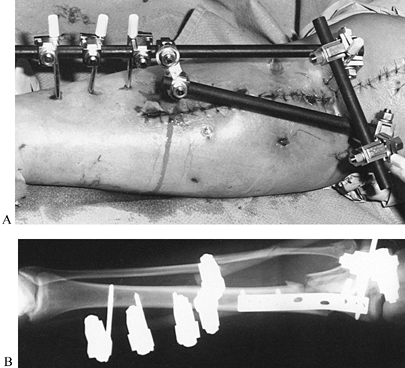

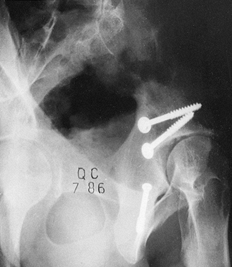

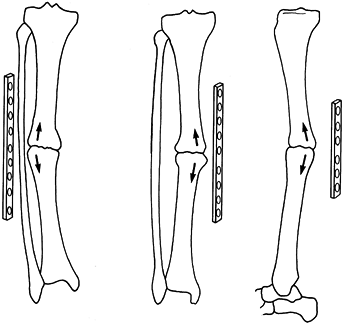

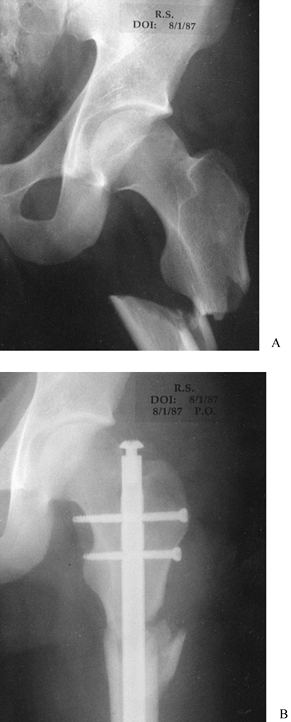

be used alone or in conjunction with internal fixation (Fig. 11.22),

what equipment is available, and what surgical skills are needed.

Determine also if the full frame should be applied immediately or

completed at a later time, and whether the fixator will remain in place

until the fracture is healed or will be replaced with a cast or

internal fixation as soon as the soft-tissue conditions permit (14).

|

|

Figure 11.22. A:

Comminuted proximal tibial fracture in an elderly patient, showing a combination of external and internal fixation to stabilize the comminuted periarticular fracture pattern in an osteopenic patient. B: Radiotranslucent carbon fiber rods facilitate assessment of the fracture site and proper timing of secondary intervention, yet provide sufficient stability to allow for soft-tissue consolidation. |

designs are preferred for patients who are heavy or who have an

unstable fracture pattern. For the younger child, a wrist or upper

extremity device may be sufficient. When rapid application is essential

or proper radiographic control unavailable, fixators with full

universal joints at both ends are ideal, because they facilitate

alignment and length adjustments at a later time (88,96).

repeated assessment of healing, devices composed of radiolucent carbon

fiber components are advantageous.

a particular fixator frame depend on the extent of the soft-tissue

injury within the safe corridor, the stability and location of the

fracture, the size of the patient, the presence

of associated lesions, the size of the fixator components, and the designs of the fixator articulations (14).

spread and provide moderately stiff components, 80% to 90% of the

applied frames are of a one-plane unilateral design (13).

For devices that provide universal articulations but lack the

mechanical advantage of maximal pin spread (e.g., Hoffmann apparatus,

Orthofix), the risk of slippage at the articulations is considerable.

With these fixators, take care to use undamaged functioning

articulations and possibly double-stacked one- or two-plane unilateral

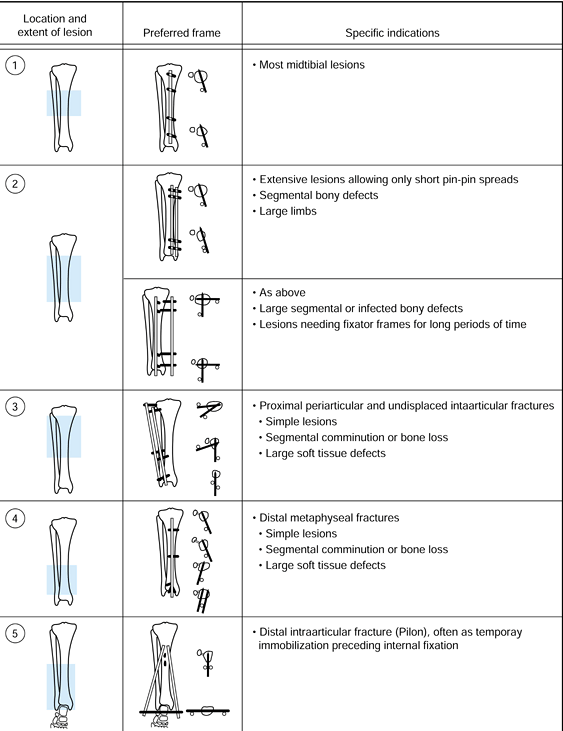

frames (96). These configurations are preferred for fractures with segmental bone loss or extensive comminution (Fig. 11.23, item 2, lower drawing). One-plane frames with double rods (Fig. 11.19, upper drawing) have a rigidity pattern similar to that of two-plane unilateral frames,

but they are less cumbersome and allow better wound access (10).

Due to their greater rotational rigidity, two-plane unilateral frames

may be still preferable for the management of infected nonunions and

lesions that are accompanied by substantial bone loss.

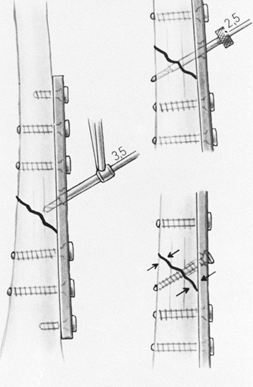

|

|

Figure 11.23.

The recommended configuration of fixator frames for different bone and soft-tissue injuries. The location and extent of the lesion is indicated, on the left, by the crosshatched area. The preferred frame is shown, with solid bars representing the pins; on the right are the indications for the use of the configuration. (From Behrens F, Searls K. External Fixation of the Tibia: Basic Concepts and Prospective Evaluation. J Bone Joint Surg Br 1985;68:246, with permission.) |

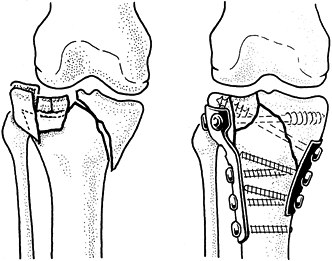

stabilizing comminuted proximal and distal periarticular fractures,

which often provide only short metaphyseal or epiphyseal fragments for

pin insertion. With simple frame modifications (Fig. 11.21B; Fig. 11.23, items 3 and 4),

however, these fractures are easily managed. Proximally, where the safe

corridor opens wide, subchondral pin placement affords anchorage for

two or more half or full pins (Fig. 11.21B, Fig. 11.21C and Fig. 11.24D). Over two or more longitudinal

rods, these pins are then rigidly connected to several distal pins,

which in the tibia are placed close to the sagittal plane. After the

application of these frames, the knee is moved through a full range of

motion to ensure free mobility of joint capsule, pes anserinus, and

iliotibial band. Distal tibial fragments as short as 2 or 3 cm long can

be stabilized by inserting two or more pins on either side of a

longitudinal rod (Fig. 11.23, item 4).

For the immobilization of distal intraarticular fractures, a talar or

calcaneal pin is connected with two rods to two or more anterior

half-pins in the proximal tibia (Fig. 11.23, item 5). Hybrid frames work well and to some extent have replaced these frames. These are presented in more detail in Chapter 23 and Chapter 25.

|

|

Figure 11.24. A grade 3 open tibial fracture with bone loss in a patient with other open fractures. A: Clinical appearance on admission. B: Radiographic appearance on admission. C,D:

Stabilization of the fracture with two-plane bilateral pin configuration proximally and three anterior pins distally. Bone graft had been delayed for 3 months because of adult respiratory distress syndrome. E: At 8 months, after the patient had started full weight bearing, the frame was gradually reduced. As a last step before removal, the proximal pin was loosened. F: Radiographs 1 year after injury. |

the management of type II or IIIA open tibial fractures with two or

three comminuted fragments. After anatomic reduction and

interfragmental compression with screws, a relatively rigid external

frame is applied instead of a neutralization plate. This approach has

been quite successful in metaphyseal fractures, which generally heal

within 2 to 3 months. In the diaphysis, however, high complication

rates, mainly in the form of refractures, have been common. This is not

surprising, because in cases of avascular diaphyseal fragments bony

union is often delayed for more than a year. Additional detail on this

issue is provided in Chapter 24.

-

Drape the limb to keep the injury zone

and the adjacent joints accessible in the operating field. Avoid

adhesive plastic drapes where pins will be inserted, as they tend to

wind up on drill points and pins and may be inadvertently transported

deep into the wound. An image intensifier helps to assess proper pin

location, pin depth, and fragment alignment, and it is particularly

valuable in dealing with closed fractures that do not allow direct

manipulation of the fracture fragments.

-

Make a skin incision just large enough to

accommodate the drill point and pin sleeves to be used. Most

manufacturers provide matched protective sleeves for drilling, depth

measurement, and pin placement. -

In deeper bones, incise the deep fascia (a small x

often facilitates guide sleeve placement); separate muscle fibers with

a Metzenbaum scissors or a small elevator and elevate the periosteum at

the pin site. Many half-pins are now available with specially designed

tips that are self-cutting and self-tapping and have flutes to deliver

bone fragments. To avoid overheating, bone necrosis, and pin breakage,

never insert these with power but rather with hand drills provided by

the manufacturer.

-

Insert the protective sleeves down to the bone.

-

Gently impact the teeth of the sleeve or trochar into the bone, if called for by the manufacturer.

-

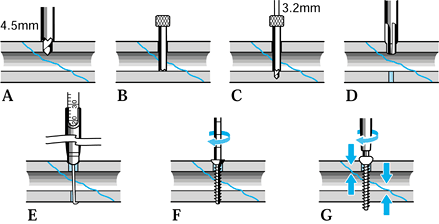

Drill the initial hole with the size

called for by the manufacturer for the pin diameter to be used. Use

power, cool the drill, and avoid overheating the bone. -

Usually one drill size suffices. In some

cases, the near cortex must be drilled with a larger diameter to

accommodate a larger smooth shank on the pin. -

Select the appropriate pin and the thread length: in some systems, a depth gauge is required, or the drill may be calibrated.

-

Insert the pin until at least one full

thread penetrates through the opposite cortex. Carefully monitor this

with the fluoroscope, as in some systems the pin cannot be reversed

without loosening. -

Many half-pin systems allow selection of

a total thread length that is 5 mm less than the overall diameter of

the bone at the site where the pin is inserted. This permits the wider

nonthreaded shaft of the pin to fit tightly into the proximal drill

hole and places a smooth shank at the level of skin. This reduces skin

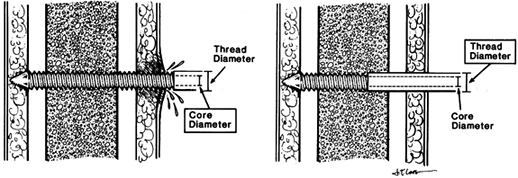

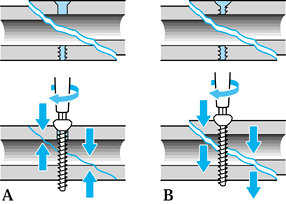

irritation and doubles the bending stiffness of the pin (Fig. 11.25). Figure 11.25. Seating of half-pins. A:

Figure 11.25. Seating of half-pins. A:

Threaded pin portion protrudes beyond the skin. This tends to cause

skin irritation and pin-tract infection. Pin stiffness is determined by

the core diameter. B: Threaded pin portion

is limited to the distal cortex. The smooth shaft rarely irritates the

skin. Pin stiffness is determined by the larger thread diameter. (From

Behrens F. General Theory and Principles of External Fixation. Clin Orthop 1989;241:15, with permission.) -

Once the entire frame has been assembled

and the fracture reduced, check the skin around each pin to be certain

that tension on one side of the pin is not present. This is indicated

by gathering of the skin. If there is tension, incise skin where it is

gathered until it lies tensionless around the pin. -

Differential motion of skin on the pin

can result in bacterial contamination of deeper tissues; therefore,

gently close any excessive incision about the pin with a fine nylon

suture that can be removed when the skin is healed.

type of fixator used. Many frames allow independent pin insertion, in

which case be certain that the limb or the fracture is aligned and

insert the next pin most distant from the initial pin. The initial pin

should have been the most extreme pin at the other end of the bone.

Insert the second pin using either a template guide or the preassembled

fixator as a guide.

proximal and distal fragments. With these fixators, independent

arrangement of the pins anywhere along a fixator bar, such as in the

unilateral frame, is not possible as the pins are inserted through a

clamp or ring that holds the cluster of pins in one fragment in a

more-or-less fixed arrangement relative to the others. The exceptions

are Ilizarov type ring fixators, where pins can be placed anywhere

along the 360° arc of the ring, and pin clamps that allow a limited

range of placing the pins longitudinally on the bone. With these

fixators, maintenance of overall alignment of the limb is less crucial,

as universal adjustment clamps permit reduction of the fracture after

the fixator has been applied; however, each fixator has a limited range

of adjustment. It is possible to apply pin clusters so out of alignment

with each other that reduction cannot be achieved. Therefore, it is

always prudent to maintain general overall alignment of the limb,

particularly rotation, as any type of fixator is applied. The following

steps describe the technique for a typical fixator of this type.

-

Using the manufacturer’s guide or the

fixator itself, insert the pins in one fragment and then the other. A

wide spread of the pins within the range allowed by the clamp increases

stability. Always apply the two outer pins on a given clamp first, to

be certain that all pins will be anchored in bone. -

Now reduce the fracture; with the

universal joints loose, obtain anatomic reduction. Tighten the

universal joints or adjustments once reduction is achieved. -

If fracture-fragment alignment is not

satisfactory on subsequent fluoroscopic examination or x-rays, loosen

the universal joints and repeat the reduction maneuver.

-

Insert one pin into each main fragment,

generally starting with the pins close to the joints (i.e., farthest

from the fracture). Maintain gross alignment of the limb (14). -

Reduce the fracture. Apply adjustable

clamps to each pin and connect them by a longitudinal rod. Then

manually reduce the fragments and tighten the two clamps to achieve

temporary reduction. Proper rotational alignment is crucial (13). -

Insert the remaining pins (10).

-

Adjust the fixator. Adjustments in the

plane of pin insertion are easily achieved by loosening the pins. For

angular adjustments in another plane, replace the longitudinal rod by

two shorter ones that are connected over a central universal joint. For

the correction of significant rotational malalignment, all pins except

one in each fragment must be exchanged.

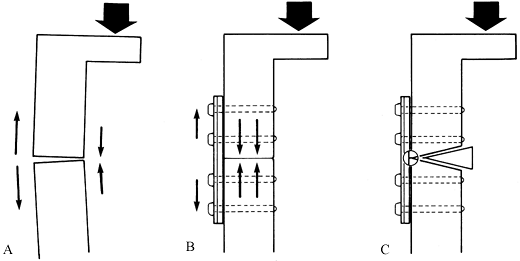

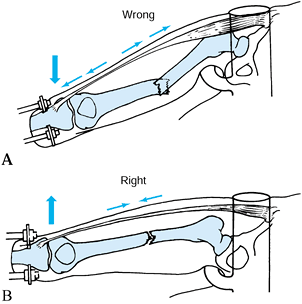

simple transverse or interdigitating fractures, axial compression of

the fracture site provides additional stability. When axial compression

is attempted with unilateral frames, the fracture fragments have a

tendency to angulate away from the longitudinal rods. It is

advantageous to start with the fracture fragments angled toward the

rod(s). With increasing compression, the fracture fragments tend to

straighten into anatomic alignment.

comparing the injured to the opposite limb, if it is uninvolved; for

assessment of alignment, however, obtain AP and lateral radiographs

that include the joints above and below.

extremity, for example in balanced suspension with the calf muscles

supported with a sling (Fig. 11.26). Support

the ankle joint in 5° to 10° of dorsiflexion with a prefabricated

splint. If the patient has sustained a severe soft-tissue injury (in

particular, compartment syndrome requiring fasciotomy, or palsy or

paresis of the common peroneal or posterior tibial nerves) or bony

injury distal to the ankle joint, replace the ankle splint with a

transtarsal pin (Fig. 11.20E) or two metatarsal pins that are connected to the external fixator frame (Fig. 11.20F).

|

|

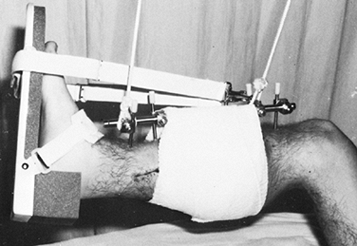

Figure 11.26.

The early postoperative management of an open tibial fracture. The limb is suspended, the calf is supported, and the ankle joint is splinted in 5° to 10° of dorsiflexion. |

passive, active-assisted, and active range of motion exercises of knee

and ankle joints. Follow with isometric muscle strengthening exercises

across both joints and mobilization with crutches or a walker. As soon

as tolerated, encourage the patient to partially bear weight on the

injured extremity, progressing to full weight bearing as the fracture

consolidates, if the fracture type and external fixator permit. If this

course is conscientiously followed, approximately 70% of all patients

with tibial fractures can advance to full, unsupported weight bearing

before the fixator is removed or replaced by a different method of

immobilization. Weight bearing has little to do with pin tract

infection or pin loosening. Patients with segmental bony defects must

be limited to bearing with only the weight of the limb.

debridements, or additional soft-tissue or bony reconstructive

procedures, the limb will generally be encased in a bulky postoperative

dressing, which precludes access to the pin sites. Because the patient

returns often to the operating room for wound debridement and

subsequent reconstruction, there is no necessity for pin care by the

nursing staff on the ward. In fact, exposing an open fracture wound on