DESIGN AND PERFORMANCE OF JOINT REPLACEMENTS

– JOINT RECONSTRUCTION, ARTHRITIS, AND ARTHROPLASTY > General >

CHAPTER 100 – DESIGN AND PERFORMANCE OF JOINT REPLACEMENTS

Director of Biomedical Engineering, Cooper Union Research Foundation,

Albert Nerken School of Engineering, 51 Astor Place, New York, NY 10003.

was interposition arthroplasty using soft and flexible materials, but

the strength of these materials was inadequate. Rigid materials such as

metal and glass in the form of condylar shapes attached to one of the

joint surfaces provided some success, but there was still a problem

with the apposing joint surface. In the knee, geometric inaccuracy

leading to poor kinematics and abnormal soft-tissue tensions was also a

problem. An interesting finding with condylar components, such as cup

arthroplasty or MacIntosh tibial plateaus, was the formation of a

fibrous membrane adjacent to the component, with a new bone plate

beneath. This tissue modeling is now recognized to develop due to

interface micromotion and to the stresses acting on the exposed

trabecular ends. Even now, implants are designed with relatively smooth

surfaces interfacing the bone; however, there is a higher incidence of

pain, migration, and loosening with these implants compared with the

more rigid methods of fixation. The success of more invasive components

with uncemented intramedullary stems, such as hemiarthroplasties and

knee hinges, depended largely on obtaining an acceptably low level of

stem–bone micromotion and interface stresses on the bone (33).

when Charnley introduced cemented metal-polyethylene components for the

hip, and in the late 1960s, when this technology was transferred to the

knee by Gunston (95). The principles proposed

by Charnley were rigid fixation of the components to the bone,

resurfacing of both joint surfaces, and the use of materials with low

friction and wear. These principles, embodied in cemented

metal-on-plastic components, have stood the test of time to this day (100,112).

of total joints used. A number of other hip designs were introduced

that were fundamentally based on the Charnley design. An exception was

the use of metal-on-metal in the McKee-Farrar design. There was a great

deal of attention to surgical technique, especially obtaining good

cement–bone apposition with high shear strength. Some total knees

proved to be successful in the long term, but others fell by the

wayside because of the lack of recognition of the kinematics, the role

of the cruciates, the patellofemoral mechanics, and the requirements

for adequate fixation. Most of the design forms used today, namely

unicompartmentals, condylar replacements with or without cruciate

retention, mobile bearing knees, stabilized condylars, and fixed and

rotating hinges, were all introduced before the end of the decade.

Ceramic-on-polyethylene and ceramic-on-ceramic replacements for the hip

had been introduced before 1980.

sophisticated instrumentation, especially for the knee, and uncemented

components with porous coatings intended for indefinite fixation. In

the knee, improved consistency of surgical technique was achieved as a

result of more accurate alignment and soft-tissue balancing. Concerning

porous coating, those designs in which rigid initial fixation was

achieved obtained sufficient bone ingrowth for long-lasting results.

Certain uncemented designs of hip stem, acetabular component, and

femoral component of the knee have shown survivorship values (54) superior to those of cemented components. A hydroxyapatite (HA) coating (104,203)

has similarly shown high durability from 5 to 10 years follow-up. The

situation today is that a number of designs of hips, knees, and other

joints have been shown to have a survivorship of greater than 90% at 10

years, such that the large majority of elderly patients can be treated

confidently. Today’s hip and knee systems offer a large variety of

sizes and modular augments to deal with virtually every situation

encountered in primary and revision surgery. The instrumentation

systems are elaborate, usually well engineered, and often too complex,

but they allow the surgeon to achieve accurate component placement and

limb alignment.

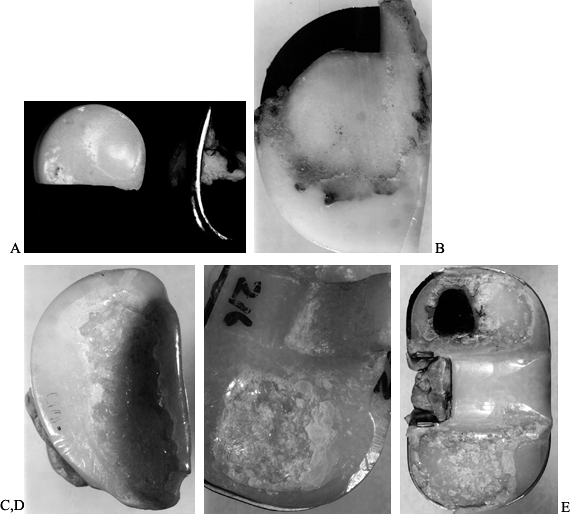

are excessive wear of the ultra-high molecular weight polyethylene

(UHMWPE) (126,236) and

loosening. These two problems are related to some extent in that the

accumulation of small particles causes a tissue response that, in turn,

produces bone resorption. However, it is now evident that wear can be

reduced in a number of ways. The main problem has been that

gamma-irradiation of UHMWPE in air, followed by gradual oxidation

either on the shelf or in the patient, has led to a degradation of

mechanical properties and an increase in the wear rate (18,140,180).

have shown a reduced susceptibility to oxidation, which has resulted in

reduced surface wear and a much lower incidence of the destructive

delamination seen in total knee replacements (TKRs) (27).

Gamma-irradiation and storage in an inert atmosphere, as well as

enhanced cross-linking and stabilization to minimize subsequent

oxidation, have resulted in reduced wear rates. For the hip joint,

ceramic-on-UHMWPE can reduce wear by as much as 50%, whereas

ceramic-on-ceramic and metal-on-metal produce minimal wear debris (65,82).

If such improved bearings are combined with superior cement techniques

or porous and bioactive coatings, much greater durability can be

expected compared with that achieved in the past 2 decades.

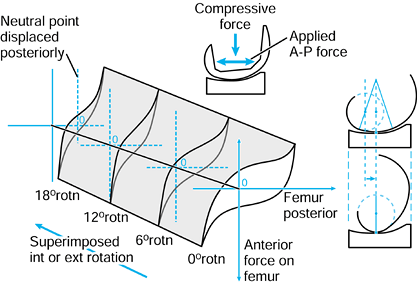

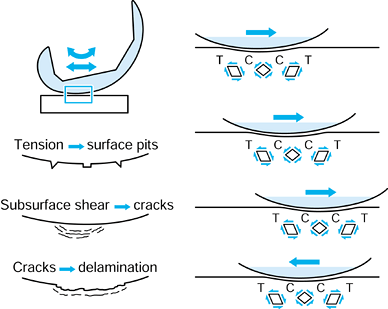

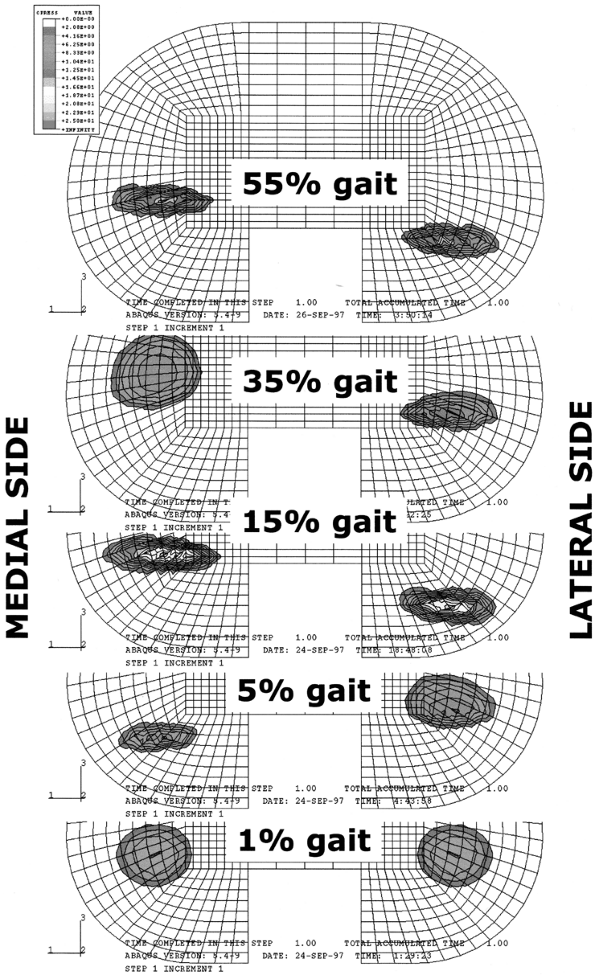

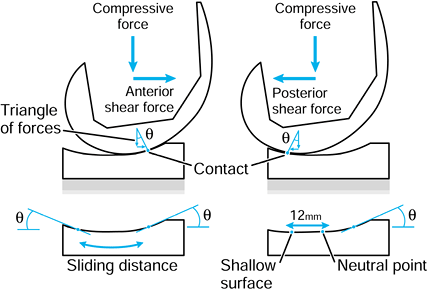

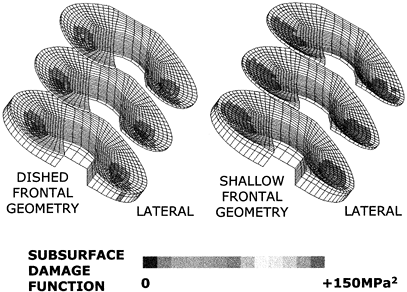

subsurface stresses is still a threat. Computer modeling of this

process has now shown how appropriate surface geometry can

substantially reduce the likelihood of delamination without

compromising the freedom of motion (189). New

advances will undoubtedly be made in the performance of TKR, especially

for younger patients. The mobile bearing concept is one such approach

for minimizing wear and improving function. However, further advances

are likely in the form of guided motion knees providing optimal muscle

lever arms and high flexion ranges. The superior functional performance

of unicompartmental replacement performed on one or both sides of the

joint opens up the possibilities of minimally invasive surgery (84),

with the option of using computer-assisted technologies. The boundary

between biologic treatments and total joints will become an issue, and

with both approaches improving and developing, the relative merits and

applications will become an area for extensive research and evaluation (59,70,72,79,141,142,152,162,165,177).

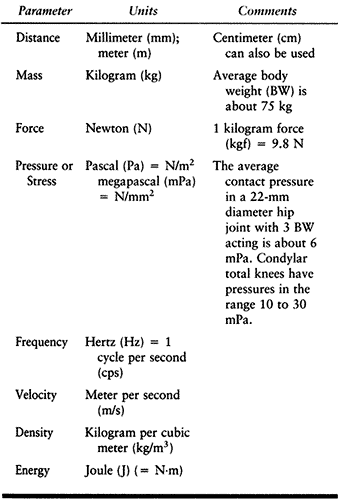

concepts of biomechanics and biomaterials relevant to joint replacement (159). The Standard International (SI) system of units (Table 100.1) is now in widespread use.

|

|

Table 100.1. SI System of Units

|

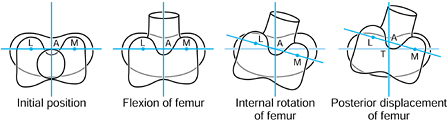

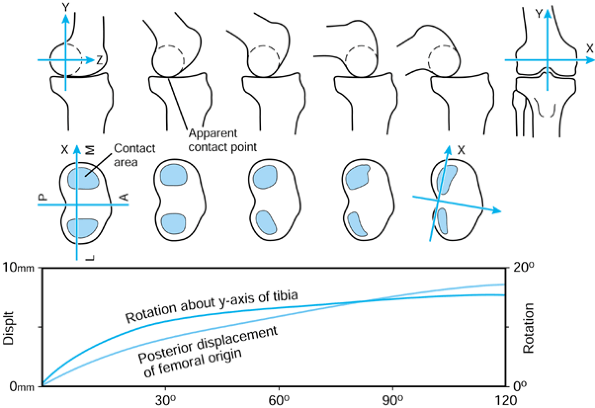

p in the negative Z direction. Finally, the femur is given an

additional displacement d along the negative Y direction. The tibia has

remained fixed with respect to the global axes, and the femoral motions

could be described with respect to an axis system fixed in the tibia.

The values F, p, and d are vectors in that they have magnitude and direction, often denoted with a line above or in bold type.

|

|

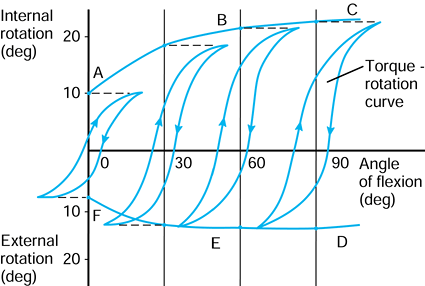

Figure 100.1.

Motion in a plane. Global axes, axes in the femur, and axes in the tibia are defined. In this case, three successive motions of the femoral axes relative to the global axes are shown: F, p, and d. |

not to be confused with the geometric centers of local radii of

curvature. If the instant center is at the center of curvature, the

motion at the contact point is called pure sliding (124). If the center is at the contact point, the motion is pure rolling (31). A center in between the two produces sliding and rolling combined.

|

|

Figure 100.2. Any two successive positions of a body in a plane can be obtained by a rotation about a single point.

|

define rotations and displacements with respect to axes, rather than

using centers of rotation (238) by the following principles:

-

Define a global axis system.

-

Define axes in each bone.

-

Define each component of motion of one axis system relative to the other.

-

Define the order in which the motions take place.

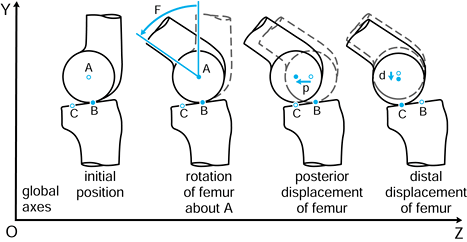

the femur is shown in its initial position on the tibia at zero flexion

with contact points L and M. The femur is first rotated by 90° (flexed)

about a transverse axis through A. Next the femur is rotated about a

vertical axis through A fixed relative to the tibial axes. The lateral

contact point moves posteriorly by a and the medial anteriorly by a. The femur is next translated posteriorly by a. The lateral contact point has now displaced posteriorly by a total of 2a,

but the medial condyle is in its original position. In orthopaedic

terms, as the knee has flexed, there has been an internal rotation of

the tibia and a posterior translation of the femur.

|

|

Figure 100.3.

Three-dimensional knee motion described by successive rotations and displacements. The figure depicts “average” knee motion from the extended to the flexed position. |

posterior displacement of the lateral contact point can occur on an

unrotated or rotated tibia, producing a slightly different end result.

The entire motion could have been achieved by a single rotation about

and a displacement along a screw axis (235),

but this is more difficult to visualize conceptually than the sequence

of rotations and displacements described. In addition, the internal

rotation and posterior displacement could have been achieved by a

rotation about a vertical axis through the medial tibial condyle.

Hence, it is important to define the method of describing the motion

and which axes are used, to avoid misunderstanding and confusion.

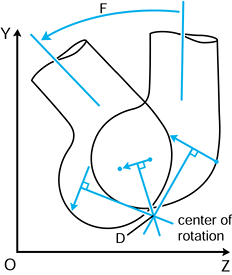

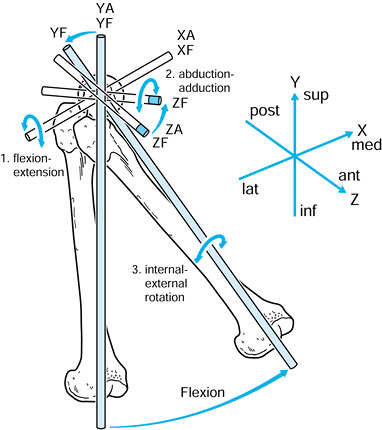

of the femoral head and the vertical axis is through the center of the

knee (Fig. 100.4). The anteroposterior (AP) and

mediolateral (ML) axes are self-evident, and all axes are mutually

perpendicular. The axes in the acetabulum and femur are conveniently

defined as being coincident with the hip in the neutral position. The

motion of the femur is defined in relation to a fixed acetabulum as

follows:

|

|

Figure 100.4. Axes in the hip joint.

|

-

Flexion-extension about the XA axis.

-

Abduction-adduction about the ZA axis.

-

Internal-external rotation about the YF axis.

The transverse axis in the femur can be chosen through the epicondyles.

The other two axes are mutually perpendicular. For convenience, the

axes of the tibia in the initial reference position at zero flexion can

be taken to be the same as for the femur. Ordered motions are defined

for the femoral axis system relative to the tibial axis system.

|

|

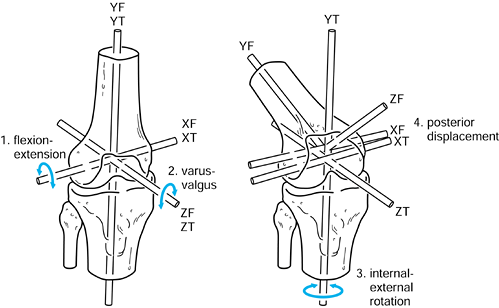

Figure 100.5.

Axes in the femur and tibia used to describe successive rotations and displacements. Flexion of the femur about XT, varus about ZT, external rotation about YT, and posterior displacement along negative ZT are shown. |

-

Flexion-extension about XT.

-

Varus-valgus about ZT.

-

Internal-external rotation about YT (this can also be regarded as rotation of the tibia about YT).

-

AP displacement along ZT.

used to define a set of order-independent motions of the knee. This is

the Grood-Suntay system (93), which has the advantage of ease of visualization.

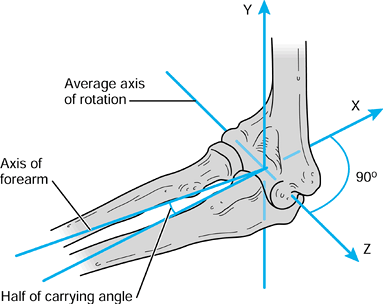

it is useful to define the axes with respect to the axis of rotation,

rather than using the long axes of the bones. The description of the

motion can then be simplified to a single degree of freedom by the

choice of the axis, which

bisects the carrying angle (Fig. 100.6).

This axis becomes a common axis in the humerus and ulna, the other two

axes being mutually perpendicular as shown. In this case, the long axes

of the bones are not coincident with the reference axes.

|

|

Figure 100.6.

For a uniaxial joint such as the elbow, one of the axes in each bone is taken along the axis of rotation, which bisects the “carrying angle.”. |

different motions and the paths from the initial position to the final

position. Successive rotations about three axes as shown in the

preceding figures are called eulerian or cardan angles (6,235). Transformation matrices

consisting of sines and cosines are used to convert the coordinates of

points on the object from the initial to the final position with

respect to one of the defined axis systems. A major interest in

artificial joints is the continuum of motion during dynamic activities,

an aspect that will be discussed later.

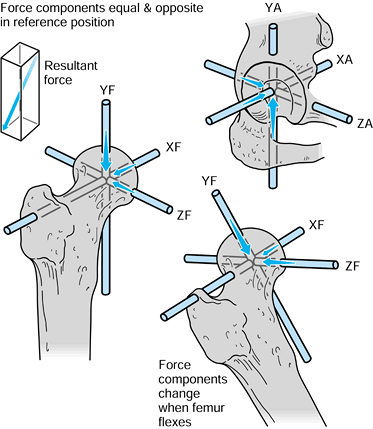

case, they have magnitude, line of action, and point of application.

Exactly the same axis systems used for the bones can be used to define

the forces. For the hip in the neutral position, there are three components of force along each of the three axes, which can be combined into a single resultant force (Fig. 100.7). The forces on the femoral head are exactly equal and opposite

to those on the acetabulum. If the femur is now moved to any arbitrary

position, the resultant forces on the femoral head and in the

acetabulum will still be equal and opposite. However, the three

components of force along each of the femoral axes are now different

from those along the acetabular axes. Hence, when defining the forces

across a joint, it is important to specify the axis system to which the

forces are referred. In reality, of course, the resultant force is

representative of the pressure acting over a large surface area.

|

|

Figure 100.7.

When the axes in the femur and acetabulum are coincident, the three components and the resultant are equal. When the femur moves, the resultant is the same, but the components along the femoral axes are different. |

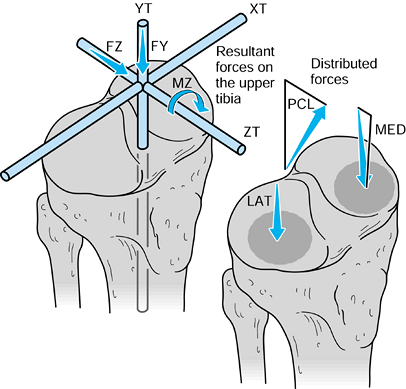

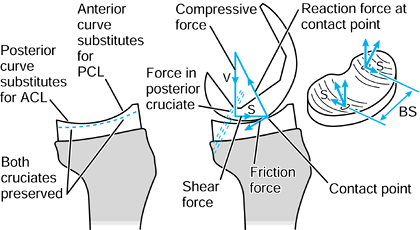

to the upper tibia. The compressive force and the varus moment produce

a larger resultant force on the medial condyle than on the lateral

condyle. The forces themselves are representative of the contact

pressures and act at the center of pressure

of each contact area. The shear force is transmitted to the tibia by

the contact areas being on the upward anterior slopes of the tibial

plateaus and by a force in the posterior cruciate ligament (PCL).

|

|

Figure 100.8.

Forces and moments acting on the upper tibia with respect to axes. The forces are shown distributed to the condylar surfaces and to the posterior cruciate ligament. |

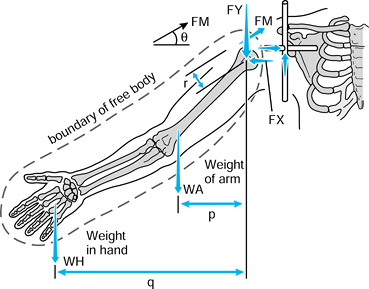

in which the problem is to calculate the forces on the face of the glenoid with the arm abducted and a weight in the hand (174). The steps are:

|

|

Figure 100.9.

To calculate the unknown forces at the joint, the forces are drawn and the arm is isolated as a “free body,” shown by the dotted line. |

-

Define axes in each bone. The humeral

axes are not drawn here because only the forces with respect to the

glenoid are considered. -

Define the forces on the glenoid. In this example, only the forces in the scapular plane FY and FX are considered.

-

Draw these forces equal and opposite on the humeral head.

-

Draw the other forces on the arm, namely the muscle forces FM, and the external forces WA (weight of the arm) and WH (weight in the hand).

-

Define the arm as a free body by drawing a boundary around it and showing the forces that act across the boundary.

radiographs), there are three unknowns, namely FX, FY, and FM. Three

equations are thus required to obtain a solution.

humeral head, so their moments are zero.) The individual values are

then solved from these three equations. This concept of isolating a

defined entity as a free body

and analyzing the forces across the boundary can be applied to numerous

force analysis problems in the body. As with motion, the changing

pattern of forces during activities is important.

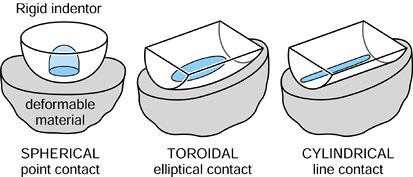

depicted with lines of action, in reality the forces are transmitted

across areas on the joint surfaces. This results in a contact pressure, or contact stress, acting on the surface (124). The density of the subchondral bone plate will provide an indication of the pressure distribution (161).

are used. Whereas static analysis, as shown in the previous section,

can be used to calculate resultant forces, to calculate pressures and

stresses in an implant-bone system, more complex analyses are required.

For simple geometries, elasticity (e.g., hertzian) equations can be

used to calculate the contact areas and stresses in terms of the radii

and the elastic properties of the materials. However, for realistic

bone and implant shapes, finite element analysis (FEA) (15,16,44,175) is the most appropriate technique.

is hemispherical, with the maximum pressure at the center being 1.5

times the mean pressure. The same situation occurs if the lower surface

is flat, a convex spherical surface, or a concave spherical surface.

|

|

Figure 100.10. Three types of contact in joints: spherical, cylindrical, and toroidal.

|

-

Higher force.

-

Lower elastic modulus (stiffness) of the materials.

-

More conforming surfaces.

-

Longer time the force is acting (due to “creep,” defined later).

-

Higher force.

-

Higher elastic modulus.

-

Less conforming surfaces.

-

For a stiff layer under a relatively soft layer.

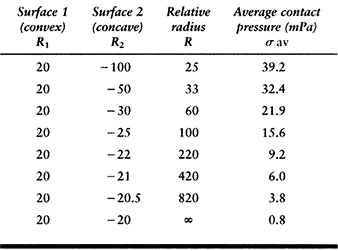

curvature for the two surfaces, and the radius of curvature is taken as

positive for convex surfaces and negative for concave surfaces.

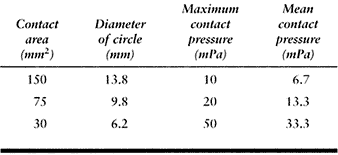

on a flat surface. The average contact pressures calculated for a given

force (1000 N) and material properties (metal-on-plastic) are shown in Table 100.2. This table shows how the relative radius and the contact

pressure change dramatically as the surfaces approach full conformity.

The range covers a nonconforming knee to a hip joint with a small

femoral–acetabular clearance (15). Note, however, that the standard hertzian equations lose accuracy when the contact radius (R2) approaches the surface radius (R1). Another factor is that the contact pressure does not necessarily predict the wear rate, which is so often assumed (148).

|

|

Table

100.2. The Relative Radii of Curvature and the Contact Pressure in a Spherical Metal-Plastic Contact, Covering the Range from Knees to Hips, for a Compressive Force of 1000 Newtons |

curvature) has a much larger contact area than does a sphere on the

same flat surface (Fig. 100.10). Examples of

arthroplasties with such contacts include some knees, elbows, ankles,

and fingers. Today, most geometries in condylar knees are toroidal,

between spherical and cylindrical, producing elliptical contact areas.

This has the advantages of reducing contact stresses and avoiding

“digging-in” at the sides if tilting occurs. The stresses beneath the

surface in all types of contacts are extremely important in both

natural and artificial joints, in terms of producing subsurface damage.

(Note that the word “stress” can be substituted for the word “pressure”

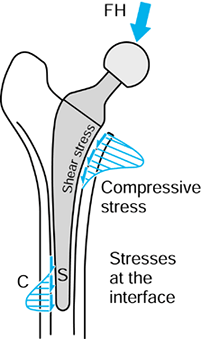

in this context.) In the case of metallic cemented or uncemented hips,

the contact pressures are highest in the proximal-medial region but

with high pressures distal-lateral also. The magnitudes of the

pressures depend also on stem geometry and head offset. For uncemented

stems, in which a “perfect” metal–bone fit is not achieved, local

contact pressures can be very high due to the stiffnesses of the

materials. An additional interface effect is due to friction between

the metal and the bone, causing shear forces to act as shown in Figure 100.11 (101,198).

If there is bonding across the interface from cement or from a porous

or HA coating, the shear forces will be higher, decreasing the

interface contact pressures. The interface shear stress is defined as:

|

|

Figure 100.11.

Interface contact pressures and shear stresses for intramedullary fixation of a hip. The magnitudes of these stresses vary considerably depending on stem design, fixation method, bone geometry, head offset, and other factors. |

-

Positive contact pressures at those interfaces that usually experience compression (e.g., acetabulum, upper tibia).

-

Minimum contact stresses on interfaces that usually do not experience compression (e.g., intramedullary canal).

-

Minimum shear stresses (e.g., acetabulum, upper tibia, intramedullary canal).

avoid intramedullary fixation, or to design the component to minimize

tension and shear.

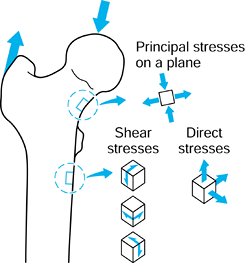

forces are acting, in general, there will be stresses acting in the

plane of the surface (Fig. 100.12). If a small square is drawn on the surface, there will be one direct stress (tensile or compressive) acting on opposite faces and another direct stress acting on the other pair of faces. There will be a single value of shear stress

acting to distort the square. If the square is now rotated, an

orientation can be found at which the shear stress is zero. The direct

stresses acting at this orientation are called the principal stresses.

One of these is the maximum and the other the minimum. Tension is taken

to be positive; compression negative. However, the principal stresses

can be both negative, both positive, or one negative and one positive,

depending on

the loading conditions around the square of surface. The maximum shear stress is at 45° to the principal stresses.

|

|

Figure 100.12.

At a location on a surface, there are two direct stresses and two shear stresses. An orientation can be found at which the shear stresses are zero. The direct stresses are now the principal stresses. A similar situation applies to a three-dimensional element of material. |

same. Here, a small cube of material is taken, which has three direct

stresses and three shear stresses. At a certain orientation, the shear

stresses are zero and the direct stresses are again called the

principal stresses.

This term is convenient in that it describes the stress state at a

point with a single number. In fact, it is calculated from the three

principal stresses, and is a value that quantifies the likelihood of

yielding, synonymous with the yield stress in direct tension.

which is the amount of energy (force × distance) stored in the material

due to the applied stresses deforming the material. This quantity is

considered to be relevant to bone remodeling, whereby the response of

osteoblasts within the bone material is proportionate to the amount of

deformation and hence strain energy density. This is an “elastic”

quantity recoverable on removal of the stresses, but yielding of the

material is an additional consideration.

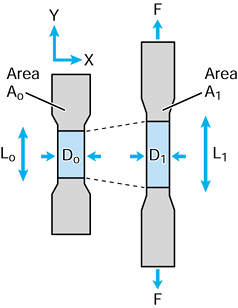

and not to the shape of the object, whether it be a bone or an implant

component. A fundamental property is modulus of elasticity E, which can be determined by a simple tensile or compressive test on a cylinder (Fig. 100.13):

|

|

Figure 100.13. A simple tensile test to calculate the modulus of elasticity E.

|

strain is small, usually measured in microstrain. A typical strain

value for the cortex of a long bone under peak load is on the order of

2000 to 3000 microstrain. For materials such as cartilage and ligament,

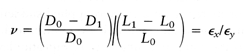

however, the strain can be 10% or more, and hence the true stress after load application must be related to the deformed area σT = F/A1, where A1 is the area with the force applied. Poissons ratio ν defines the strain in directions perpendicular to the longitudinal strain:

0.4, and for an incompressible material such as a fluid or rubber, ν

equals 0.5.

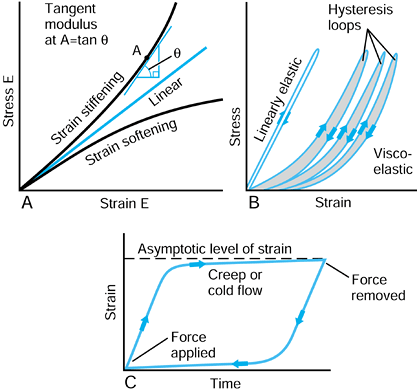

but increases steadily with strain. Rubbers usually exhibit strain

stiffening also. Conversely, materials such as polyethylene exhibit

strain-softening behavior, in which the elastic modulus appears to

reduce with strain. For these nonlinear materials, modulus of

elasticity has to be defined as a tangent modulus at a particular value of strain, as shown in Figure 100.14A.

|

|

Figure 100.14. A: Metals usually have a linear stress-strain curve. Biologic materials, rubbers, plastics, and composites are usually nonlinear. B:

An elastic material recovers its initial shape immediately on load removal. For a viscoelastic material, there is a residual displacement and a hysteresis loop. C: Characteristics of creep or cold flow, when the load is maintained over a period of time, and then removed. |

is an immediate strain, followed by a continued strain at a decreasing

rate, reaching an asymptotic level (Fig. 100.14C). The behavior is called creep or cold flow.

When the force is removed, the reverse process occurs. Polyethylene

behaves in this way, as does articular cartilage, tendon, and ligament.

Stretching exercises before a sporting activity put such tissues

through viscoelastic and creep cycles. Acrylic cement, when subjected

to sustained loading in a fluid environment at 37°C, shows some creep,

and this may be relevant to the slight sinkage of polished hip stems

over time.

if a property such as modulus or strength is much greater in only one

particular direction. Most biologic materials are orthotropic, which

results from their structure, either aligned collagen fibers in the

case of ligament and tendon, or aligned osteons in the case of bone (128).

Articular cartilage is a special case with complex properties due to

its triphasic composition of collagen fibers, mucopolysaccharide

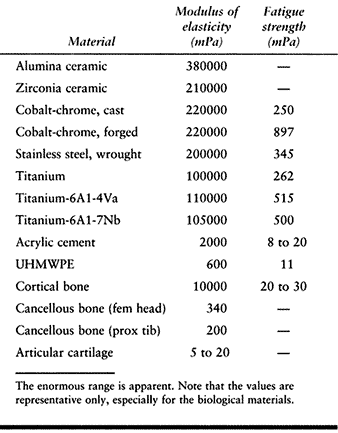

matrix, and fluid. The values of modulus of elasticity for the

materials discussed cover a wide range (Table 100.3),

and consequently, the transfer of forces between different structures

is complex and can involve regions of stress concentration.

|

|

Table 100.3. The Modulus of Elasticity and the Fatigue Strength of Biological and Artificial Materials

|

either tension, compression, or shear. In general, tensile failure is

the most common. If a material is stretched and fails suddenly, that is

termed brittle fracture. Ceramics and acrylic cement behave in this way. Metals and polyethylene, on the other hand, are ductile in that there is a region of plastic deformation whereby the material elongates at essentially the same applied load. If the load is released, there is a permanent deformation,

but the material can continue to be structurally useful in that

condition. Permanent deformation in plastic tibial and patellar

components is an example. Tendons and ligaments behave as if they were

numerous fascicles in combination (41,241),

with rupture of the tightest fascicles occurring first. If the load is

released and sufficient fibers are intact, the structure can still

function. Bone is close to being brittle, although there is some

plastic deformation due to pull-out of osteons from the matrix (58,128,159).

the level at which single cycle yield or fracture occurs due to

repetitive cycling of forces, a process known as fatigue. This process has been observed on many orthopaedic devices including hip stems (93) (Fig. 100.15), tibial trays (1), and plastic liners (Fig. 100.16). The fatigue strength or fatigue limit is the stress below which no failure would occur no matter how many cycles of loading occurred (Table 100.3).

This value is generally about two thirds of the failure stress for a

single-load application. Fatigue failure initiates at the location of

the highest stresses, and the crack gradually propagates through the

section until the stress reaches the level at which complete failure

occurs at a single load. The starting point of the crack can be a small

defect in the material structure, such as an intergranular defect in

metal or plastic (205). Even a reference

number of a component etched onto a metal surface in a highly stressed

region has been the initial location of a fatigue crack. Such defects

are called stress concentrations or stress raisers in that they raise the stress level above the overall average level in that region (106).

Sharp edges, corners, or grooves in implant components are common sites

of stress concentration. Even defects just within the material, such as

small bubbles in cement, can act as stress concentrations in the same

way. Generally, biologic materials do not experience fatigue failure

because the resting periods between loading episodes allow for

restoration and remodeling. However, one theory for the development of

osteoarthritis has been advanced: healed trabecular microfractures,

failed in fatigue, produce an overly stiff supporting structure to the

articular cartilage.

|

|

Figure 100.15.

A fractured revision hip stem, in which the lower part of the stem is rigidly supported but the proximal region was relatively unsupported, especially medially. |

|

|

Figure 100.16.

Fatigue cracks in an UHMWPE tibial component. This is due to a degradation of mechanical properties from oxidation in a component that had been on the shelf for several years. |

change rapidly from section to section, especially in the presence of

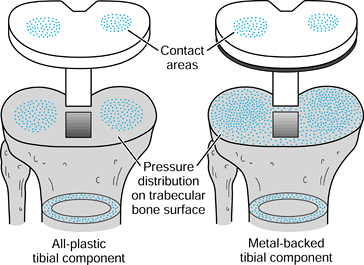

implants. Combinations of bone and implant are called composite structures. An example of a component that acts in series with the bone is a metal-backed tibial plateau (Fig. 100.17).

It is assumed that the resultant forces on the plastic surfaces are

similar for the all-plastic and metal-backed components. However, at

the resection level of the upper tibia, although the forces transmitted

across this section are the same, the distribution is quite different.

In the case of the plastic, there are high stresses directly under the

contact areas. In contrast, the metal plate spreads the load over the

entire upper tibia. The actual pressure distribution largely reflects

the foundation stiffness of the underlying trabecular bone (154). At an individual trabecular level, the stresses are largely compressive in a vertical direction in the normal knee, but are

varied and complex beneath an artificial knee, depending on the

penetration and closeness of contact of the cement. At the level of the

cortex, below the implant level, the stresses in the prosthetic case

are similar to those of the normal knee.

|

|

Figure 100.17.

The stress distribution on the upper tibial surface depends on whether the component is all-plastic or metal-backed. In the latter case, the distribution reflects the foundation stiffness of the trabecular bone. In the cortex, the stresses are equal and resemble normal. |

These two stress distributions are combined to produce the resultant

stresses. The bending stresses usually dominate over direct stresses

such that the lateral side is still in tension and the medial side is

in increased compression.

|

|

Figure 100.18.

The stresses in the bone at a section just below the lesser trochanter, for the intact femur, and after insertion of a hip stem. See text for details. |

is called the bending stiffness. In practice, a hip stem has a much

higher EI value than the bone for a narrow cortical thickness and large

canal diameter. In this case, the proportion of the bending carried by

the stem is high, and the bone can be seriously stress protected. At the other extreme, with a thick cortex and a narrow canal, the bone carries a high proportion of the bending.

Human joints are different from most bearings in engineering in that

they operate under low sliding speeds and are expected to last a

lifetime. Furthermore, they are constructed of a thin soft layer on a

relatively hard layer, carry out motions in multiple directions, and

are not necessarily fully conforming. The way in which they function so

effectively is in maintaining a layer of viscous fluid between the

cartilage surfaces such that direct rubbing of cartilage on cartilage

occurs infrequently (227). A number of

different lubrication mechanisms known in engineering have been found

to apply to human joints, but their behavior is so complex that there

is no direct analogy. The coefficient of friction,

defined as the ratio of the frictional shear force to the compressive

force, ranges from about 0.001 to 0.01. This means that, for a typical

compressive force of 3 body weight (BW) (2000 N) on a hip or knee, the

shear force is a mere 10 N. In contrast, a metal-polyethylene joint

would have a shear force of at least 10 times that. Although friction

is usually associated with sliding between two surfaces, a frictional

shear force can also be transmitted during rolling, up to the level

determined by the dynamic friction coefficient. The motion in that case is termed tractive rolling.

During a lightly loaded swing phase, synovial fluid is drawn in between

the joint surfaces. On applying a force at the start of stance, a fluid

film is maintained by a squeeze film

mechanism, whereby the large surface area and the viscosity of the

fluid mean that leakage of the film occurs at a very low rate. As

movement begins, the film is further maintained or even enhanced by elastohydrodynamic lubrication,

by which the area of contact is maintained due to the deformations of

the bearing surfaces and fluid is pressurized as it is drawn into a

thin converging wedge between the surfaces. In addition, as the

cartilage surfaces are deformed, fluid is exuded between the surfaces

(this has been termed weeping lubrication)

and at the leading edge of the contact area. Fluid becomes trapped in

small undulations in the cartilage surfaces, a mechanism called trapped pool lubrication, and a higher concentration of

hyaluronic acid can result in a more viscous layer of synovial fluid, by so-called boosted lubrication.

The hyaluronic acid protein complex chemically binds to the cartilage

surface so that even if sliding occurs when there is minimal film

thickness, boundary lubrication is provided.

lubrication mechanisms are ineffective because of the hardness of the

materials and the limited surface areas, so that surface-to-surface

rubbing takes place during sliding. At each step, it is estimated that

millions of submicron-sized plastic particles are released into the

joint. The effect of wear on particles and osteolysis of the bone

around the interface, as well as the mechanical effects of the change

in geometry, are major limiting factors in the durability of artificial

joints (82).

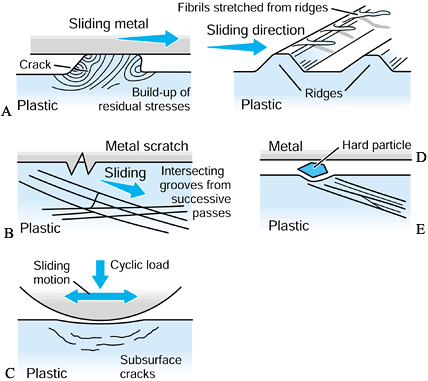

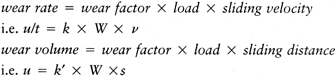

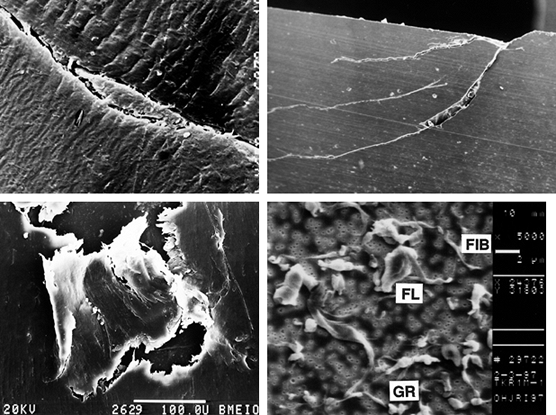

visualized as the sticking of a tiny region of the plastic surface on

to the metal surface such that a fragment of plastic is pulled away (Fig. 100.19). It is now thought that such a mechanism may require multiple passes to build up sufficient strain energy in the asperity

(a local high point) before it is released. A variation of this

mechanism occurs when the adhesion results in a small fibril of plastic

being stretched from an asperity and eventually released. The next

mechanism is abrasive wear (83). In two-body abrasive wear,

small sharp asperities on the metal surface, such as scratches, cut

into the plastic surface. Crisscrossing of scratches on the plastic due

to variations in motion paths accelerate this type of wear. Three-body abrasive wear occurs due to the entrapment of small particles between the sliding surfaces (51).

In artificial joints, these particles can be plastic, acrylic cement,

bone, HA, or metal debris from rough or sprayed surfaces. If such

particles embed into the plastic surface, they can accelerate the wear

locally. All of these mechanisms produce particles in the range of 0.1

µm to a few microns. The particle shapes are granules, fibrils, or flakes (47,48).

For ceramic-on-ceramic or metal-on-metal joints, the wear mechanisms

are similar but the rates of volumetric wear are much smaller than for

metal-on-polyethylene joints, and the particle sizes are also smaller.

|

|

Figure 100.19. A representation of different wear and damage mechanisms from a plastic surface: adhesive wear (A), two-body abrasive wear (B), three-body abrasive wear (C), delamination (D), and fretting (E).

|

This is a fatigue process whereby shear stresses at about 1 mm beneath

the surface change in direction as sliding and rolling take place,

initiating and propagating cracks in the material (176).

When the cracks reach the surface, fragments of plastic are liberated.

A surface once disrupted fragments at a rapid rate. It is noted that,

because delamination is affected by subsurface stresses, it can occur

due to rolling as well as sliding, although the stress magnitudes are

slightly higher in sliding. Pitting is

another fatigue damage phenomenon caused by tensile cracks initiating

at the surface. The effect is usually local, seen as pits about 0.5 to

1.0 mm in diameter. The severity of both delamination and pitting

depend on the fatigue properties of the material, which, in turn, may

depend on time-dependent phenomena such as oxidative degradation (62,77,135,180,182).

-

The material properties change (e.g., due to yield, surface heating, in vivo oxidation, chemical effects).

-

The surface of an initially polished hard material becomes scratched.

-

Transfer films occur (e.g., due to surface heating, degraded joint fluid).

This occurs due to cyclic shear stresses across an interface between

two parts intended to be statically fixed together. Examples are a

modular femoral head on a taper and a plastic insert in a metal

backing. The shear stresses can be generated due to elastic

deformations from cyclic loading, including the Poissons effect. The

latter occurs, for example, when the plastic of

a

tibial component becomes squeezed radially outward from a contact area.

The motion due to the interface shear stresses can be submicron or even

up to a millimeter in a loose snap-fit connection.

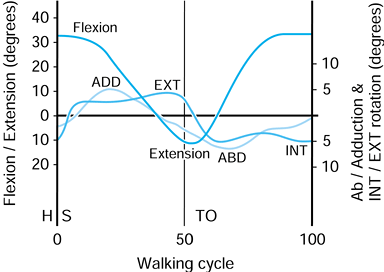

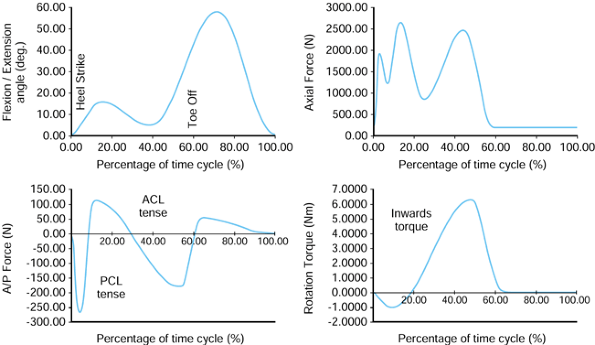

On heel-strike, there is about 30° of flexion, and at toe-off, about

10° of extension. The other two rotations are approximate because of

the difficulty of separating femoral from pelvic motion. However, the

range of abduction to adduction is about 11°, and for internal-external

rotation, the range is about 8°. These rotations produce motions of

individual points on the femoral head that traverse curved paths in the

socket and cross over one another. This aspect is discussed further in

the section dealing with hip-simulating machines.

|

|

Figure 100.20.

Representative values for the rotations occurring in the hip joint during normal walking. (Data from Inman VT, Ralston HJ, Todd F, eds. Human Walking. Baltimore: Williams & Wilkins, 1981.). |

determined indirectly by using gait analysis and directly in total

joints by using telemetry (20,21,187).

The latter is more applicable to the subject of this chapter. These

forces have been depicted as acting on the femoral head during

different activities. Figure 100.21 shows that

the line of action of the force during level walking changes much less

than the angles of motion of the femur relative to the acetabulum. The

projection on the acetabelum of these forces during walking results in

a similar pattern but with larger angles of excursion. This means that

the force vector moves somewhat more with the femur than it does with

the acetabulum (74,75). The reason for this is that approximately two thirds of the hip force is produced by the abductors (10), which tend to apply their force parallel to the long axis of the femur (74,75).

|

|

Figure 100.21.

The magnitudes and directions of the forces on the femoral head during the stance phases of different activities. (The data were determined by using telemetry [21].) |

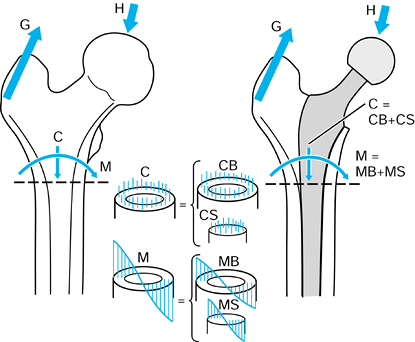

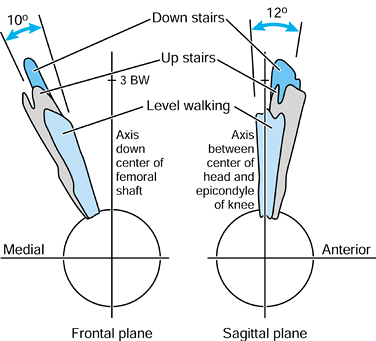

important to the function of total hips. For this purpose, it is useful

to consider the forces relative to axes based on the long axis of the

femur. In the frontal plane, the force makes an angle of 15° to 27° to

the long axis of the femur during stance. This produces axial

compression, a varus moment, and a medial-to-lateral force. In the

sagittal plane, there is an important component peaking at

approximately 0.75 BW acting from an anterior to posterior direction on

the femoral head, which results in torsion (21,99).

The latter is considered to be an important contributor to the

compressive failure of trabecular bone in uncemented stems, and results

in stem fractures initiating from an antero-lateral corner.

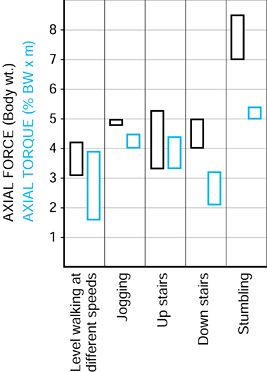

The exceedingly high force of 8 BW encountered accidentally in a

stumble is important because a single force such as this, along with

its torsional component (21), could lead to debonding at the implant–bone, cement–bone or cement–stem interfaces, or to cracking of the cement mantle (22,150,210). A factor that influences the mechanics of the hip is the offset of the femoral head from the femoral axis (167,184).

This is frequently reduced from normal in a total hip replacement

(THR). The effect is an increase in the force required in the abductors

(10), leading to a higher resultant joint

force, a more vertical resultant, and sometimes a gait abnormality. An

increase in offset reduces forces but causes an increase in the bending

moment on the stem. Failure to achieve the

normal anteversion of the head and neck increases the axial torsion, which is undesirable (21).

|

|

Figure 100.22.

The ranges of the peak forces in different activities measured by telemetry in two different subjects. (Data from Bergmann G, Graichen F, Rohlmann A. Hip joint loading during walking and running, measured in two patients. J Biomech 1993;26:969.) |

little since the original Charnley design, although paradoxically, even

a small change in design can result in a major change in performance.

Fundamentally, the stem shape parallels the canal shape (167),

leaving space for a cement mantle of 2 to 4 mm in thickness. In early

designs such as the Charnley, Exeter, Stanmore, Muüller, and T28, the

cement was not intended to bond to the stem. In contrast, at the

cement–bone interface, these designs aimed for an intimate mechanical

contact with rough bone or trabecular bone. Compressive, shear, and

tensile stresses are transmitted to the bone surface (113), an unnatural situation, but one that is tolerated for long time periods.

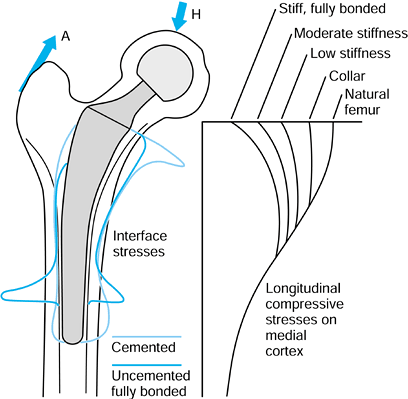

changed from normal due to the presence of the stem, especially

proximomedially, where the longitudinal compressive stresses are

reduced to 20% to 30% of normal levels (110,223) (Fig. 100.23).

Progressing distally, the stresses become closer to normal, reaching

normal levels below the level of the stem tip. The reduction in a

stress parameter, such as the Von Mises stress, particularly when it

results in a reduction of bone density or volume, is called stress protection or stress shielding (30).

Over a time period of approximately 5 to 10 years, this results in

longitudinal removal of bone at the neck cut level, osteopenia, and

resorption of bone away from the cement. If this process becomes

extreme, the interface stresses around the remaining stem become

excessive (150), leading to “clinical” loosening (94).

In addition, wear particles can be more easily transported down the

interface, producing lysis at locations all around the stem, especially

distally (98). A further consequence of

proximal bone loss is that the stem is only rigidly fixed in its distal

half, increasing the bending stresses and increasing the possibility of

fatigue fracture (94).

|

|

Figure 100.23.

Typical direct (compressive and tensile) stresses at the bone interface, and the longitudinal compressive stresses in the bone, after cemented or uncemented stems. The proximomedial stress-shielding is least with a functional collar and most with a fully bonded stiff stem. Some data are adapted from various papers by R. Huiskes and colleagues (see, e.g., references 113,114). |

become the standard method for measuring and monitoring changes in bone

density over time (201,202).

In this technique, in the frontal plane, for example, an x-ray beam is

scanned across the field, and measures of x-ray absorption are made,

giving a measure of bone mass at a matrix of points in the field. Major

changes in bone mass usually occur slowly, and it has been found that

bone loss may be only 10% to 20% at 2 years, but that this loss can

increase to as much as 50% in the proximal-medial region at 5 years.

known only approximately, but the goal is to minimize these stresses

and to avoid local stress concentrations. Stresses within the bone

should be as close to normal as

possible.

Cement and stem stresses, especially tensile, should be minimized and

should not exceed the fatigue limit under normal loading conditions.

All of these goals cannot be obtained simultaneously, but a number of

guidelines for hip stem design exist:

-

Stem bending stiffness should be much lower than that of the bone to minimize stress shielding.

-

Avoid excessively flexible stems that elevate interface tensile and compressive stresses and produce excessive micromotion.

-

Ensure that the cement mantle thickness is a minimum of 2 to 3 mm (122) (can be achieved using centralizers).

-

avoid corners or any other feature on the stem that would cause stress concentrations in the cement or in the stem itself (22).

-

Create smooth contours but with sectional shapes that will not twist within the cement mantle.

-

Provide features such as proximolateral

projections (e.g., “cobra” design) to provide a greater connection

between stem and cement, a net increase in compressive stresses, and a

reduction in tensile stresses -

Provide a means of centralization,

especially proximomedial and distal, to avoid close metal–bone

proximity, where lysis frequently occurs. -

Use third-generation cementing

techniques, including cleaning the canal, distal plugging,

pressurizing, and minimizing porosity (12,145)

long-term clinical data suggest that a smooth surface or a near-smooth

surface, in which there is no direct stem–cement bonding, produces

successful results. The use of rough surfaces, or rough surfaces with a

precoating of cement to obtain stem–cement bonding, has not been

uniformly successful. It appears that shear and tensile stresses at the

interface can cause progressive debonding and interface micromotion (150).

The latter can then generate metal and cement debris, which enter the

joint space, followed by accelerated wear of the UHMWPE liner. Evidence

of stem–cement micromotion in all types of stem is frequently seen in

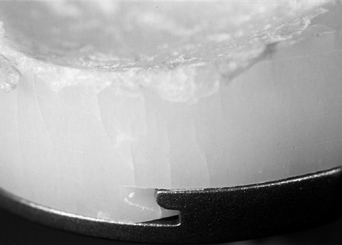

retrievals and produces fretting wear of both stem and cement (Fig. 100.24).

|

|

Figure 100.24.

A retrieved hip stem showing that the original matte surface has been polished smooth due to micromotion between the stem and the cement. This is due to fretting wear. |

and forged cobalt-chrome or stainless steel is usually preferred.

Titanium alloys have been prone to surface wear or even crevice

corrosion and are not in general suitable for cemented application. The

ideal combination for a cemented stem with a modular head is to use

cobalt-chrome alloy for both owing to the minimal corrosion on the

taper connection (31) and reduced scratching of

the femoral head over time. Other head materials are discussed later in

this chapter. Because of its success in elderly patients, and even in

younger patients (12,71,145)

(although studies are variable on this issue), it is unlikely that the

design of the standard cemented stem for primary cases will change

substantially in the foreseeable future. Long-stem cemented components

are used in revisions, but the cement penetration and shear strength

are likely to be inadequate owing to the loss of most of the cancellous

bone from the previous implant (146).

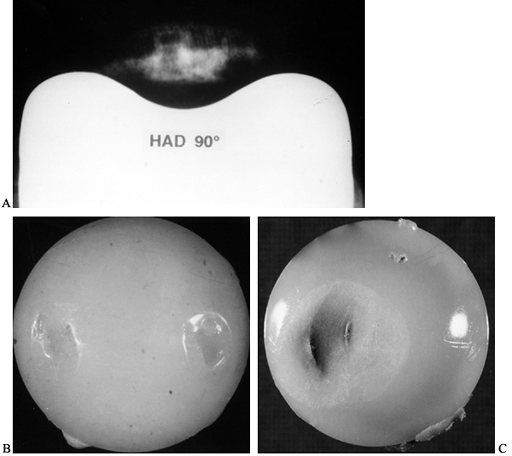

solid UHMWPE hemisphere, or just greater than a hemisphere, with

grooves on the outer surface for keying to the cement. A metal wire is

usually embedded on the outside to measure the wear relative to the

femoral head on radiographs. The range of motion (ROM) between the

femoral neck and the socket before impingement occurs is important

because it affects the potential for dislocation as well as loosening.

It is notable that, as wear proceeds, the ROM steadily reduces, and

this process can lead to problems for 22 mm heads in the long term. The

factors affecting ROM are:

-

ROM increases with head diameter. (However, there is an increase in volumetric wear with diameter.)

-

ROM increases with decreasing neck

diameter. (This is especially applicable to flexion-extension, in which

the neck can be elliptical.) -

ROM decreases with a short neck if collar-socket impingement occurs.

-

ROM decreases with “skirted” femoral heads, which increase head height and offset.

-

ROM decreases in certain planes if the socket and stem are malpositioned.

diameter in the range of 26 to 28 mm with an elliptical neck of minimum

diameter for strength. In practice, the most widely used diameters are

28 mm and 22 mm. To obtain sufficient plastic thickness the minimum

outer diameters of the acetabular component recommended for a 28 mm

diameter head are 44 mm for plastic and 48 mm for metal-backed plastic.

Below those diameters, a 22 mm head is recommended.

are the same as those for stems, notably intimate contact of the cement

with a rough bone surface and penetration within the trabeculae. There

is still uncertainty regarding removal of the subchondral plate (161) and the size and number of key holes (Fig. 100.25).

Although retention of a subchondral plate is attractive for force

transmission, areas of relatively smooth bone are prone to interface

micromotion, bone resorption, and particle ingress. The loosening

mechanism of cemented acetabular components is that the peripheral

regions become infiltrated with UHMWPE debris, leading to bone

resorption, followed by a creeping process that eventually involves the

entire interface (192). This process has been

conceptualized as a progressive increase in the “effective joint

space.” Mechanical factors are also likely to play a role due to higher

than normal stresses occurring in the trabecular bone (64).

Steady migration of sockets into the acetabular bone is common, and

acetabular component failure usually occurs at a higher rate than for

stems in follow-up examinations after more than 10 years. The use of

metal backing (115), which reduces the

incidence of interface radiolucency in tibial components, has not been

successful in cemented acetabular components. Simple finite element

models indicated a more uniform stress distribution across the

interface, but more complex 3-D models, which included the exact

shapes, bone densities, and forces acting (64),

have shown otherwise. This has highlighted the care needed in

formulating and interpreting finite element models and the conclusions

that may be drawn from them.

|

|

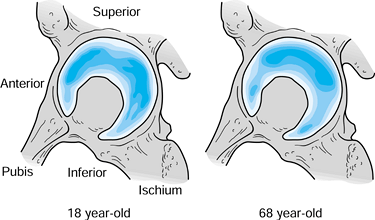

Figure 100.25.

Density of the subchondral bone in the acetabulum for two different ages. Assuming that the density reflects load transmission, in youth (left), there is more even distribution, which gradually converts to more localized superolateral load transmission over time (right). (Data from Muüller-Gerbl M. The Subchondral Bone Plate, Vol 141. Advances in Anatomy, Embryology and Cell Biology. Berlin: Springer-Verlag, 1998.) |

hemispherical shells were interposed between reamed surfaces of the

femoral head and acetabulum in the expectation that new cartilaginous

surfaces would form between the metal and the bone. The tissue

formation, however, was unpredictable, consisting of localized islands

of fibrocartilage and hyaline articular cartilage. There may still be

possibilities for this type of approach if the type of tissue formation

can be controlled to a greater degree. The Austin-Moore and similar

hemiarthroplasties, generally with rectangular sectioned stems, were

moderately successful with regard to fixation and pain relief, although

most of the patients had limited functional requirements. Subsequently,

many such uncemented stems with “satin” or smooth interface surfaces

have been introduced in total hip stems, but have all been subject to

bone resorption, interface micromotion, and migration, leading to

unsatisfactory results.

achieving tolerable stresses at the implant–bone interface and

minimizing interface micromotion to approximately 50 µm or less over

most of the interface. These conditions depend on the surface of the

stem, the sectional shape, and the overall geometry. The major factors

are

-

Stem Surface.

Smooth or satin stem surfaces are unsatisfactory and become surrounded

by a thin layer of fibrous tissue and a bony shell, which is linked to

the cortices with trabecular struts. Rough surfaces have been

successfully used in designs such as the Zweymuller (PLUS,

Endoprothetik AG, Switzerland) in cases in which rigid mechanical

fixation with the diaphysis has been achieved at surgery. In suitable

stem designs, porous surfaces have shown at least 25% of the surface

area ingrown by bone, which has proved to be adequate for long-term

fixation (42,80). The rate of bone ingrowth and the percentage of area ingrown are enhanced with HA or HA-tri-calcium phosphate (TCP) coating (203).

Such coatings superimposed on rough or macrogrooved surfaces have

demonstrated enhanced bone growth around the periphery of the stem, but

bone

P.2590

has been sparse when gaps have been greater than approximately 1 mm (90,203).

In all of the above-mentioned cases, the strongest bone attachment and

areas of new bone formation have been where the implant was in contact

with cortical bone or strong cancellous bone, in regions where high

forces are transmitted (42,80,194). -

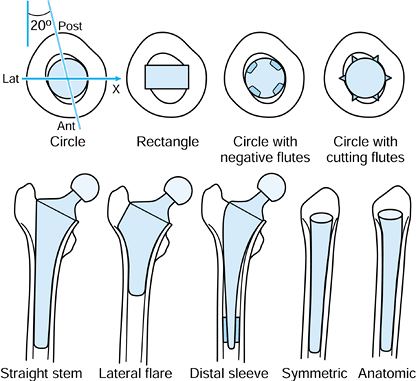

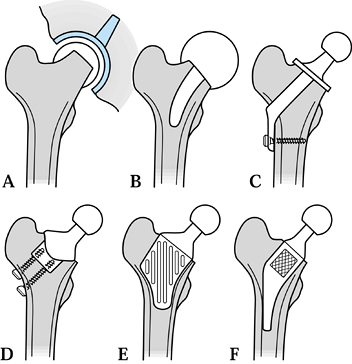

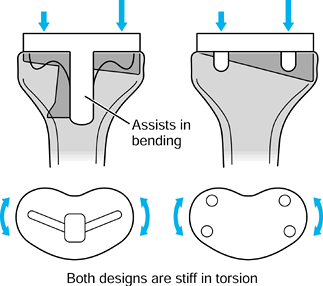

Stem Sectional Shape (Fig. 100.26).

Circular or elliptical sections have the least potential for bone

attachment, except where an initial interference fit is achieved and

the stem is rough or coated. Corners that cut into the bone have been

successful, but again only for certain surfaces and where the overall

stem geometry has avoided excessive stresses at the stem corners.

Grooves cut into the stem provide little benefit unless they are

provided with a bioactive coating such as HA. On the other hand,

multiple cutting flutes, especially when combined with a rough surface,

provide stable fixation, particularly in torsion (232). A useful application of such flutes is in revision stem design (131) Figure 100.26.

Figure 100.26.

The shape and orientation of the normal diaphyseal canal is shown. The

most rigid fixation of stems occurs when the corners of a rectangular

stem or longitudinal cutting flutes cut into the cortical bone.

Osseointegrated straight stems provide rigid fixation at the expense of

proximomedial stress-shielding and difficulty of removal. The lateral

flare provides rigid fixation and allows for a shorter stem, especially

when designed anatomically in the ML view. -

Overall Stem Geometry. In the frontal view, most stems are either straight or have a lateral flare (Fig. 100.26).

Generally, it has been found that reliable long-term fixation is

obtained when rigid initial fixation has been achieved and most of the

stem is rough or coated to promote subsequent bone apposition or

ingrowth. Two examples are the Zweymuller and the AML (DePuy, Inc.,

Warsaw, IN). The main disadvantage of this approach, especially when

the stem is both porous coated and long, occurs when removal of an

ingrown stem becomes necessary. The lateral flare designs with a high

neck cut attempt to maximize proximal fit-and-fill such that the stem

can be of reduced length. This is possible because the proximal shape

reduces the bending moment on the stem and also provides rigid axial

load support. The stems are usually anatomic in shape, as seen in the

ML view, to maximize the proximal fill. A question with uncemented

stems is the number of sizes needed to provide adequate fit both

proximally and distally in the large majority of cases. Some designs

address this by using modular distal sleeves (50).

Collars are an effective way of increasing the compressive stress

component in the proximal femur, but this can be achieved reliably only

if there is osseointegration into the underside of the collar (57,71).

more proximal stress shielding than a cemented stem owing to its larger

cross-sectional area (38,80).

Laboratory tests have shown that this is not necessarily the case

because the stem becomes tightly wedged in the femur, producing high

circumferential tensile stresses as well as up to 50% of the axial

compressive stress component (226). Where

proximal bone ingrowth has been achieved, bone has been well preserved

over time, based on DEXA-scanning data. However, serious proximal bone

loss has occurred under the following conditions:

-

Rigid distal fixation and inadequate proximal fixation.

-

High bending stiffness of stem compared with bone (80) (i.e., thick stem, thin cortex)

-

Excessive stem length.

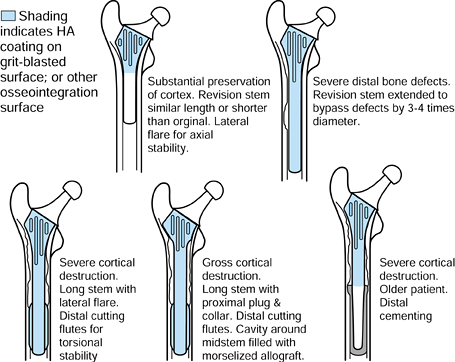

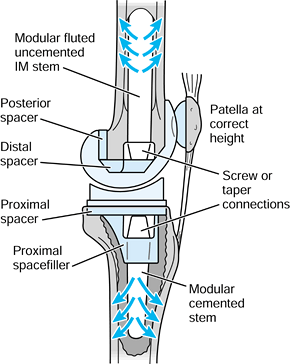

revisions. The major goals in the design of a revision stem are to

maximize axial and torsional stability, and to preserve or enhance the

remaining bone. To achieve these goals, the following features are an

advantage:

-

A stem with distal longitudinal cutting

flutes and a bone attachment surface (e.g., rough or HA-coated) to

provide torsional, axial, and bending stability; if necessary, the long

stem inserting into the diaphysis past the level of the previous stem. -

A proximally filling stem with cutting fins and grooves, and a bone attachment surface to attach to and load the proximal bone.

-

A lateral flare to enhance axial stability, increase proximal bone loading, and reduce the bending moments on the distal stem

as well as patient factors, a graduated implant system is logical,

basing the design decision on a hierarchy of factors (Fig. 100.27).

Modular systems using separate proximal “plugs” and distal stems, or

using a hollow proximal sleeve with a stem that locks within it (as in

the S-ROM [DePuy-J&J, Warsaw, IN] system) (45)

are useful approaches in dealing with these variations in an

off-the-shelf system. A fragile or detached greater trochanter is

problematic and can be held by hooks or wires. Circumferential bone

wiring reduces hoop stresses on surgical insertion but may cause stress

concentrations in future years. The most difficult revision situation

occurs when the diaphysis below the level of the failed stem is thin.

Here, the choice is between impaction allografting (91),

with a risk of migration, or a very long uncemented or cemented stem

affixing in the femoral condyles. The long stem can even be rigidly

attached to a knee replacement in those cases in which both the hip and

knee need revising or replacing.

|

|

Figure 100.27.

A graduated approach for a revision hip system in which various design features are added according to the condition of the femur and status of the patient. |

made for providing a custom hip for every case, provided the surgery is

suitably precise (14). For a cemented hip,

there must theoretically be an ideal thickness and shape of cement

mantle and an ideal stem length. For an uncemented hip, there must be

an ideal fit and stem length to minimize interface micromotion (109) and produce the ideal combination of interface and bone stresses (110,232).

In all cases, the ideal position of the femoral head can be obtained.

However, the issue is complex, and separate considerations apply to

cemented or uncemented, primary or revision (49,131). Some of the factors that are noted in the argument against the widespread adoption of custom stems are as follows:

-

The stem design itself is only one part

of the total operative procedure. Larger variations in clinical results

may occur owing to technique variables rather than owing to the stem

design. This point includes the fact that custom stems are not

necessarily positioned in the intended location in the femur. However,

a “Robodoc” type of approach (computer-controlled milling of the

femoral canal based on preoperative computed tomographic [CT] imaging)

might provide the eventual answer to this problem (14,171). -

Long-term deterioration of fixation, such

as interface bone resorption and “clinical loosening,” may be dominated

by biologic factors at the interface, including the effect of wear

debris. -

There are no validated theoretical models

for determining the ideal shape for a hip stem for any particular

femoral geometry. Hence, the nearest fit from an off-the-shelf system

may be as favorable as a custom design if the latter is designed by

nonvalidated rules. -

Achieving an accurate fit-and-fill of a

stem to the cortical bone (or an exactly uniform cement mantle) may not

produce the ideal conditions for long-term success (181).

This has been demonstrated for a closely fitting stem, but one without

a surface that provided osseointegration, such as porous or HA coating. -

There are insufficient randomized and

well-documented studies demonstrating that for routine use, a custom

stem system produces better long-term results compared with an

off-the-shelf system of comparable design features. Furthermore, the

clinical measures—other than outright failure, which requires long

follow-up and large numbers—are insufficiently sensitive to distinguish

between two stem designs. -

The variations in femoral geometry are

contained within a sufficiently narrow boundary that a multisized

off-the-shelf system, in combination with reamers and rasps that can

modify a given femur shape, can achieve an accurate fit in the large

majority of cases. -

The logistics of producing custom hips

involve additional technologic steps to determine the 3-D geometry of

the femur, such as scaled radiographs (119), CT reconstruction, or even direct shape determination at surgery (160,181),

such that there is a significant increase in the cost and

administrative steps required, and there may be excessive delay in

producing the custom hip

problems, there is still a justification for using custom hips in

primary cases and even more so in revisions. It has been shown that

very low rates of loosening, even superior to that obtained with

cemented stems, can be achieved by using fully porous-coated or

HA-coated stems that are fixed tightly into the diaphysis by

appropriate reaming. However, proximal stress shielding is an

undesirable consequence with this system. If the more preferable

proximal stem fixation is required, the fit requirements are more

stringent. In this situation, custom hips have an advantage. There is

considerable empirical data that interface micromotion is the major

cause of pain and bone resorption, and laboratory data have shown that

micromotion can be minimized by implants with a close fit to cortical

bone (46). Hence, in a large series of cases,

custom stems should reduce the incidence of pain and interface

radiolucency compared with an off-the-shelf design with the same design

features (Fig. 100.28). Even if an

off-the-shelf hip is used for the more “normal” anatomies, custom stems

may still be used for abnormal situations. For revision hip

replacements, the variations in the proximal shape after removal of the

original stem, the diameter and curvature of the diaphysis below that

region, and the required location of the femoral head are so great that

a custom approach has a strong justification. Indications for custom

hip replacements are:

|

|

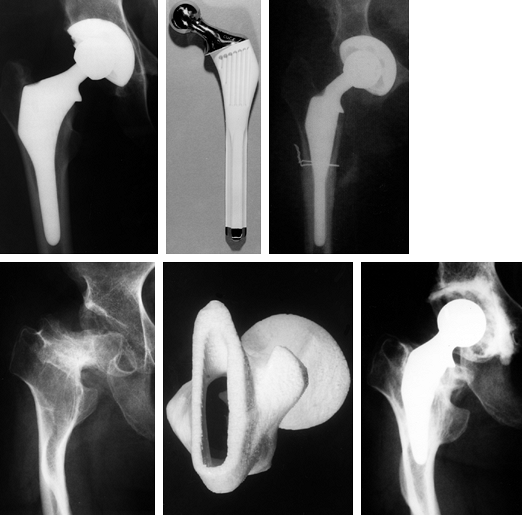

Figure 100.28. Examples of custom hips used in primary cases, in which the anatomy ranged from normal to grossly abnormal. Top left: A custom hip used for normal anatomy. Top right:

Subtrochanteric osteotomy in a 90° anteversion congenital dislocated hip using longitudinal cutting flutes across the osteotomy. Bottom: Grossly abnormal geometry for which CT scans were used to design a tongue-shaped stem and a stereolithographic plastic model was made for preoperative trials. |

-

Congenital dislocated hip (CDH), in which

the femoral anteversion is in the range of approximately 30° to 60°.

The custom stem is designed to fit the canal closely and to restore the

normal 15° to 20° of anteversion. -

CDH in which the femoral anteversion is

in excess of approximately 60°. Here, a subtrochanteric osteotomy is

performed, the upper femur is rotated correctly at surgery, and the

custom stem is designed with longitudinal cutting flutes to provide

torsional stability across the osteotomy site (Fig. 100.28). -

CDH, juvenile rheumatoid arthritis (JRA),

or other conditions in which the hip is exceptionally small or has

severely abnormal anatomy (Fig. 100.28). -

In hips that are extremely large, or with

large canals, for which the custom hip is made hollow or slotted to

reduce the bending stiffness. -

After osteotomy, trauma, or other

conditions, with abnormal geometry, sometimes requiring an osteotomy at

surgery to restore normal geometrical relations -

Canals with extreme bowing in either the

AP or ML views or with an overhanging greater trochanter, requiring a

“banana-shaped” stem -

In revisions due to the wide range of

bony conditions, proximal shape and bone loss, stem length required,

anterior bow, distal diameter, and relation between the proximal and

distal dimensions. A graduated approach is especially appropriate for

revision hip replacements, as described earlier (Fig. 100.27).

A number of commercially available software packages can be used to

contour the inside and outside cortical bone boundaries, from which a

3-D model of the bone can be generated. The internal contouring

requires definition of a suitable Hounsfield number (a value signifying

bone density, where 100 equals water and 1000 equals cortical bone)

distinguishing the boundary between cancellous and cortical bone. For

purposes of reaming and rasping, a value of 500 to 600 has been shown

to be suitable. Another method for determining the shape of the femoral

canal that is more direct and less expensive but is restricted to

femurs of relatively normal shape is to use scaled AP and ML

radiographs (119). The canal outlines are

digitized and then a 3-D computer model of the “average femur” is

numerically distorted so that its canal outline fits that of the

specific femur. This method has been shown to be accurate to better

than 1 mm in the regions where a close stem fit is required.

is needed to design the stem to a particular scheme. For example, it

can be assumed that distal reaming and proximal rasping are performed

to produce a more geometric shape for ease of manufacture and surgery.

The general principle is such that the major load transmission occurs

proximally (110), which results in the following ideal features:

-

Medial, lateral, and anterior flares.

-

A collar with a coating for osseointegration.

-

A close-fitting proximal stem with an osseointegration coating.

-

Proximal macrogrooves to minimize

micromotion and provide additional bony stability should there be any

deterioration of an HA coating -

A relatively short and smooth distal stem to restrict its function to controlling bending rather than transmitting axial forces.

custom hip replacements, prewritten computer numerically controlled

(CNC) software is required. This software provides instructions to a

milling machine to produce the stem from a bar of preformed material.

The end result is an integrated software package that covers both the

design and manufacturing stages.

custom hip system compared with an off-the-shelf system is to assume

that accuracy of fit is the single criterion for comparison, and then

to determine how many off-the-shelf

sizes

would be needed to fit the general population of femurs to a given

accuracy. This requires that the most ideal set of sizes for the

off-the-shelf system be synthesized. The problem can be solved in the

following way:

-

Produce a “training set” of approximately

100 successive osteoarthritic cases for which custom hip replacements

have been produced, excluding shapes that clearly are outliers. -

Define the shape of the stem by p geometric variables, such as coordinates of numerous key points around the stem periphery.

-

Use “principal component analysis” to reduce the variables, using linear combinations of the variables that best express the p-dimensional scatterplot of the original variables

-

Synthesize an n-sized system such that if n = 1, that is the geometric mean, and if n > 1, the sizes synthesized provide the best fit for the largest number of the training set.

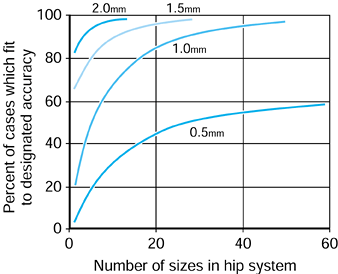

can be produced. If an accuracy of fit of 0.5 mm or better between the

stem and the bone were required, then a 40-sized system would achieve

this in just under 50% of all cases. However, if a 1 mm accuracy were

satisfactory, a 20-sized system would deal with more than 80% of all

cases. Virtually all cases could be dealt with using a 10-sized system

if only 1.5 or 2 mm accuracy were required.

|

|

Figure 100.29.

Principal component analysis was used to synthesize best fit off-the-shelf hip systems with different numbers of sizes in the system. The percent of cases in the general population fitted to the specified accuracy is shown. |

replacement, namely surface replacement, the problem of fit is greatly

simplified. Such an approach can be classified as a conservative hip,

which can include several forms. A conservative hip is one that

involves fixation to the femur and acetabulum such that its removal for

any reason would allow the placement of standard primary hip components

with little compromise. Early examples of conservative hips are the

Aufranc cup arthroplasty and the various femoral head replacements with

short pegs, such as the Judet (212). From the

1970s to the present, various surface replacements have been attempted

using combinations of metal, ceramic and polyethylene for the

components, and press-fit, cement, porous, and HA for fixation. There

have been several problems with surface replacement to date:

-

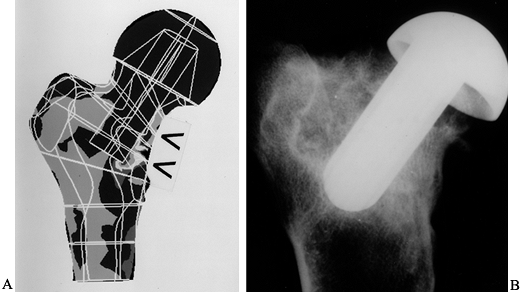

The bone has remodeled inside the head to exaggerate the load transmission to the medial calcar, as predicted by FEA (Fig. 100.30).

Figure 100.30. A:

Figure 100.30. A:

The FEA analysis (Von Mises stress) shows decreased bone stress under

the head and increased stress in the medial calcar region. B:

The radiograph shows a conservative hip after 1 year in a goat, showing

bone resorption under the head, and new trabeculae where the stem is

close to the lateral cortex. -

Subsequent degradation of the implant–bone interface and overall loosening.

-

Fracture of the neck level with the rim

of the head component. The risk can be minimized by avoiding excess

reaming, as well as by details of component design. -

Excessive reaming of the socket to

accommodate sufficient thickness of UHMWPE. This has been solved by

using thin shells of a cobalt-chrome (Co-Cr) alloy, a metal-on-metal

bearing -

In cases of avascular necrosis of the femoral head.

A modification to a standard surface replacement is Townley’s TARA

design. This design removes most of the head, greatly reducing the

trabecular remodeling problem, whereas the short stem improves

stability. Thrust-plate designs (e.g., Wiles, Huggler and Jacob) have

met with some success in clinical follow-up, and further improvements

to this type are possible by using surface textures and coatings for

osseointegration. Advantages of this configuration are that good

initial stability can be obtained to allow for osseointegration, and a

normal modular head can be used. A key issue is that a proportion of

the varus bending is transmitted by the neck collar and by the lateral

plate because this has important remodeling consequences. Variants of

the thrust-plate design use different fixation at the neck resection

level, within the neck itself, and at the lateral cortex. FEA of hip

stems with a lateral flare indicates that, for a high neck cut, the

stem carries only a small bending moment, allowing its length to be

shortened considerably. This provides the possibility of a “proximal

plug” type of conservative hip. In this type, osseointegration can

occur over a large surface area. Preserving part of the femoral neck

for bone support is used in the Mayo conservative hip design (Zimmer,

Inc., Warsaw, IN) and in the Pipino hip. Other conservative hip schemes

include metal shrouds that cover regions of the outer proximal femur.

Such designs could have application for abnormal femoral geometries and

even for some revisions. From the acetabular perspective, those

conservative designs that incorporate a femoral

trunnion to use a standard modular head have an advantage for restoring the required head offset.

|

|

Figure 100.31. Different designs of conservative hip: (A) metal-on-metal surface replacement (Amstutz, McMinn); (B) capping design with stem (Townley TARA); (C) thrust plate (Huggler-Jacob, Wiles); (D) stemless design (Munting & Verhelpen); (E) proximal CAD-CAM (Santori-Walker); (F) Mayo Conservative Hip (Morrey).

|

stems with each other can be divided into laboratory studies and

clinical evaluations.

view, sagittal view, and the sectional fits, from a given stem size

range, in a representative selection of femurs. The goal with cemented

stems is to achieve a uniform cement mantle thickness around each cross

section, as well as minimum values of around 2 to 3 mm from distal to

proximal. For uncemented stems, the goal is to achieve stem–cortical

contact at those areas determined by the design philosophy, such as

around the entire distal stem or on the lateral and medial flares. From

a practical point of view, contact can be considered to be within a

defined tolerance level such as 0.5 or 1.0 mm (119).

In actual evaluations of this type on typical uncemented stems, it has

been found that there is only a small percentage of contact with

cortical bone.

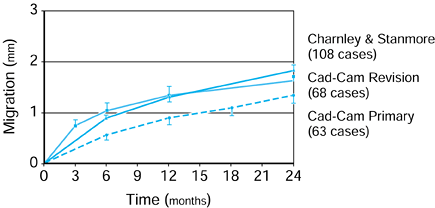

component is fitted into a plastic or cadaveric bone, cyclic forces are

applied to

the femoral head in a test machine, and the stem–bone motion is measured over time (193).

It has been found that the stem subsides progressively, usually

reaching an asymptotic limit after a few hundred cycles. The total

subsidence is called “migration.” Thereafter, there is a cyclic elastic

deformation between the stem and the bone, termed “micromotion.” The

values of micromotion are usually in the range of 10-200 µm (109).

It is estimated that a value of about 50 µm is acceptable before

interface bone resorption would occur. Generally, better fit, a more

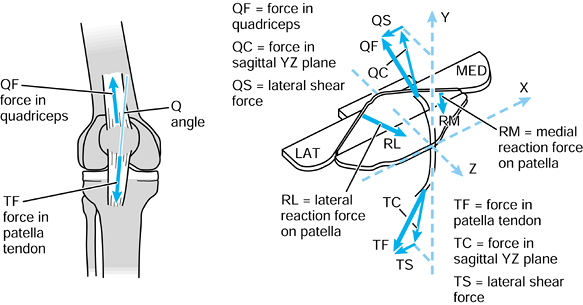

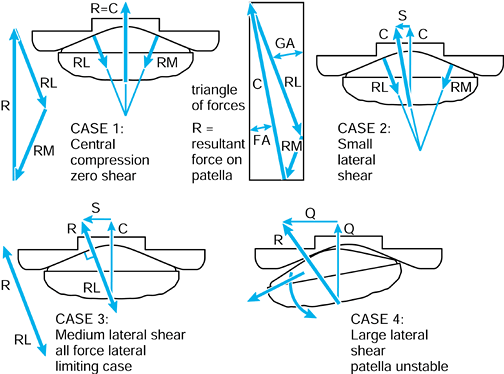

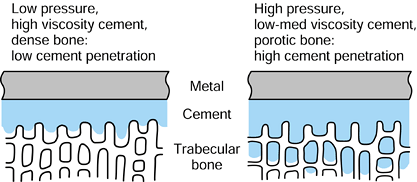

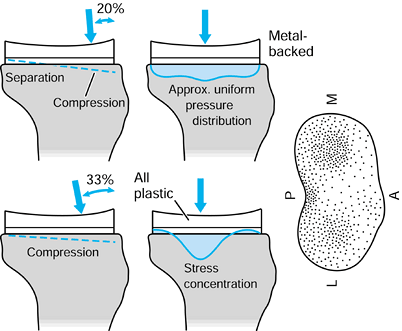

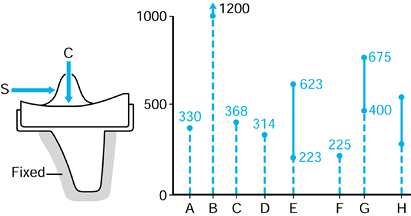

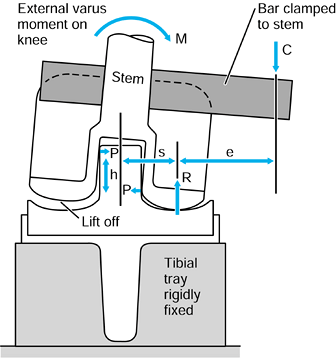

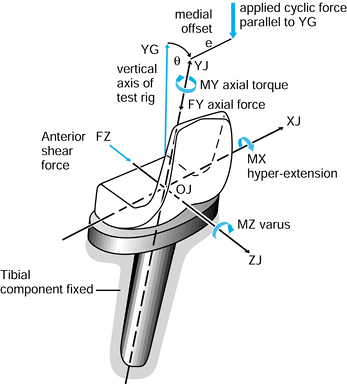

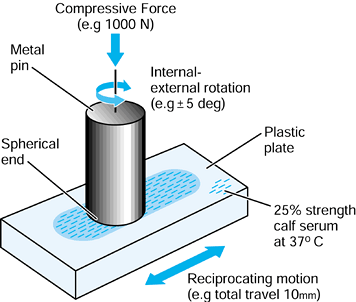

anatomic stem, the presence of a lateral flare, and more cortical